Room temperature phosphorescent carbon dot material and its preparation method and application

A room-temperature phosphorescence and carbon dot technology, applied in luminescent materials, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve the problems of unstable performance of carbon dots and low yield, and achieve stable phosphorescence performance , high efficiency and good room temperature phosphorescent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] On the one hand, an embodiment of the present invention provides a method for preparing a room temperature phosphorescent carbon dot material. The process flow of the preparation method of the room temperature phosphorescent carbon dot material is as follows: figure 1 As shown, it includes the following steps:

[0030] Step S01: dissolving acrylamide, urea and citric acid in water in proportion to prepare a mixture solution;

[0031] Step S02: performing hydrothermal reaction treatment on the mixture solution in a sealed environment, and then performing purification treatment.

[0032] Specifically, in the step S01, acrylamide, urea and citric acid jointly constitute raw materials for preparing room temperature phosphorescent carbon dot materials. In one embodiment, during the process of dissolving acrylamide, urea and citric acid in water in proportion, the mass ratio of acrylamide, urea and citric acid is controlled to be (1-8):(2-6): (0.1~1.0), the specific three ...

Embodiment 1

[0046] The first embodiment provides a room temperature phosphorescent carbon dot material and a preparation method thereof. The room temperature phosphorescent carbon dot material is prepared according to a method comprising the following steps:

[0047] S11: Weigh 4g of acrylamide, 4g of urea and 0.5g of citric acid respectively for use;

[0048] S12: Put the weighed acrylamide, urea and citric acid into 20mL ultrapure water (the water resistivity is 18.4MΩ·cm -1 ) in a beaker, stir well;

[0049] S13: Put the above-mentioned mixed solution into a 30mL polytetrafluoroethylene reactor, and heat the reactor in an oven at a constant temperature of 200°C for 36 hours, and the temperature will be room temperature;

[0050] S14: Put the brown solution obtained after the reaction into a 500Da dialysis bag, and dialyze it in a beaker with 2L ultrapure water to remove impurities and obtain a light yellow carbon dot solution;

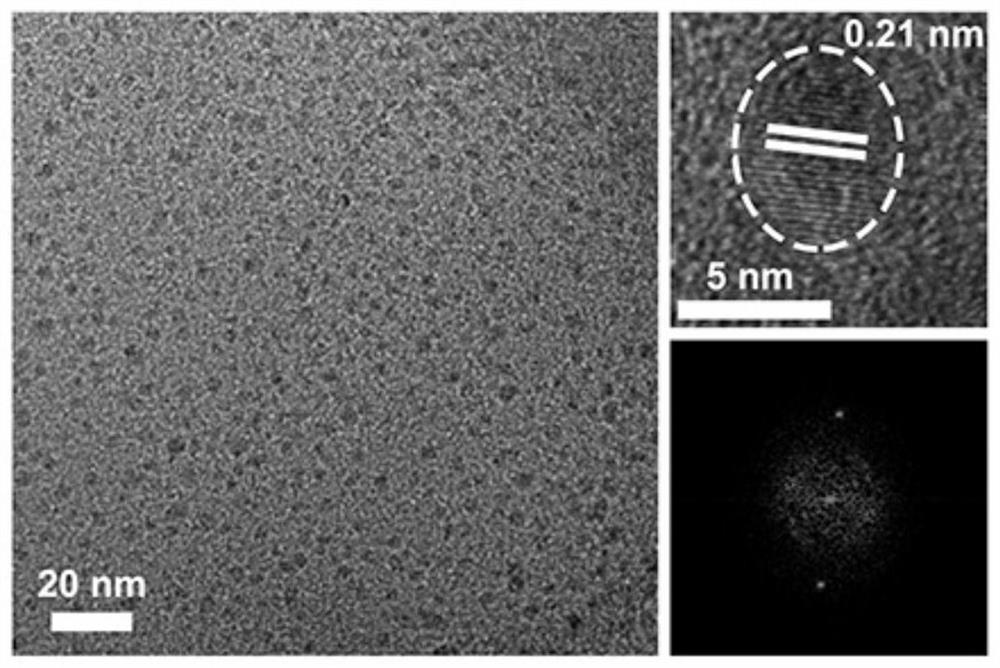

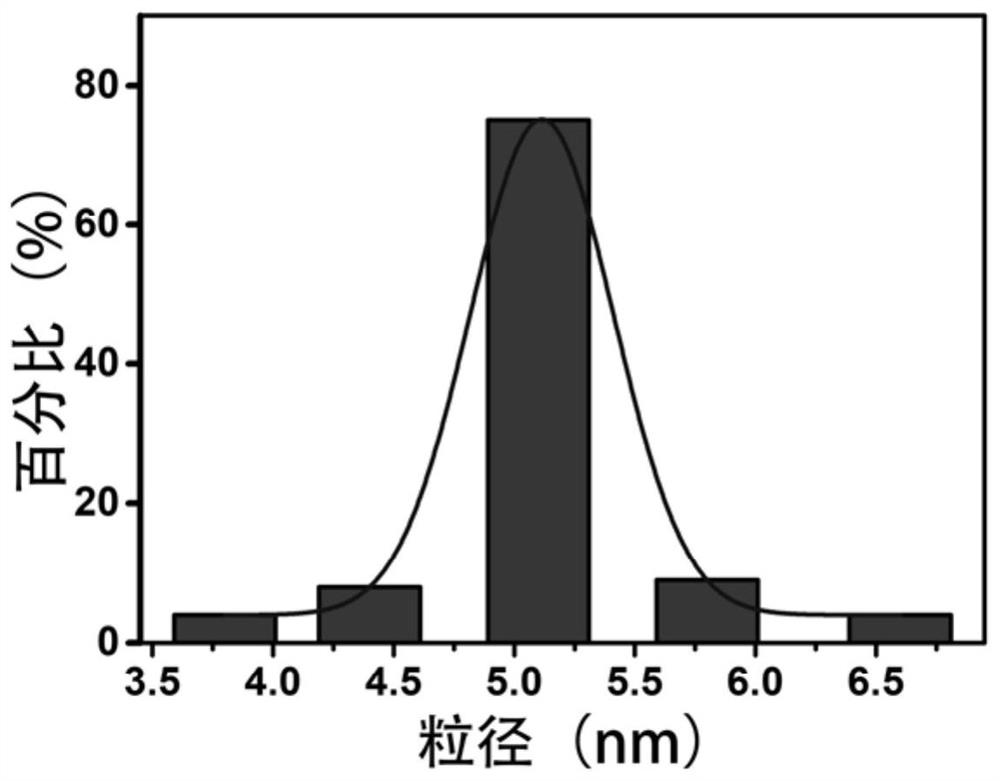

[0051] S15: Put the obtained light yellow carbon dot s...

Embodiment 2

[0053] The first embodiment provides a room temperature phosphorescent carbon dot material and a preparation method thereof. The room temperature phosphorescent carbon dot material is prepared according to a method comprising the following steps:

[0054] S11: Weigh 1g of acrylamide, 4g of urea and 0.5g of citric acid respectively for use;

[0055] S12: Put the weighed acrylamide, urea and citric acid into 20mL ultrapure water (the water resistivity is 18.4MΩ·cm -1 ) in a beaker, stir well;

[0056] S13: Put the above-mentioned mixed solution into a 30mL polytetrafluoroethylene reactor, and heat the reactor in an oven at a constant temperature of 200°C for 36 hours, and the temperature will be room temperature;

[0057] S14: Put the brown solution obtained after the reaction into a 500Da dialysis bag, and dialyze it in a beaker with 2L ultrapure water to remove impurities and obtain a light yellow carbon dot solution;

[0058] S15: Put the obtained light yellow carbon dot s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com