Preparation method of power coconut oil with coconut flavor

A coconut oil and coconut fragrance technology, which is applied in the directions of fat oil/fat production, fat generation, etc., can solve problems such as being unsuitable for children and the elderly, greasy taste, narrow tablet application range, etc., to save raw material costs, easy to absorb, namely good melting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

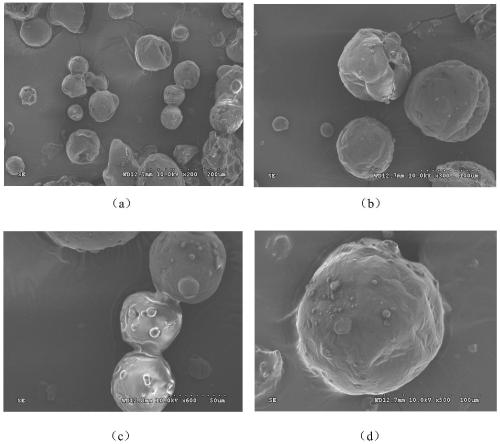

Image

Examples

Embodiment 1

[0033] A kind of preparation method of coconut fragrance powder coconut oil of the present embodiment, described method specifically comprises the steps:

[0034] 1) Select fresh coconut meat without mildew and no rot, wash the coconut meat and crush it into shredded coconut, then squeeze the shredded coconut at a temperature of 50-75°C. pulp;

[0035] 2) get the coconut milk obtained in 10kg step 1), and add L-sodium ascorbate in the coconut milk, mix, wherein: the add-on of described L-sodium ascorbate is 0.05% of coconut milk quality;

[0036] 3) Add sodium caseinate, guar gum, maltodextrin, sucrose successively to the coconut milk in step 2), fully dissolve and mix to obtain emulsified coconut milk, wherein: the sodium caseinate, guar gum , maltodextrin, and sucrose are added in amounts of 0.50%, 0.50%, 15%, and 4% of the concentrated coconut milk mass respectively;

[0037] 4) The emulsified coconut milk obtained in step 3) is sterilized under pasteurization temperature...

Embodiment 2

[0041] A kind of preparation method of coconut fragrance powder coconut oil of the present embodiment, described method specifically comprises the steps:

[0042] 1) Select fresh coconut meat without mildew and no rot, wash the coconut meat and crush it into shredded coconut, then squeeze the shredded coconut at a temperature of 50-75°C. pulp;

[0043] 2) get the coconut milk that 10kg step 1) obtains, and add sodium nitrite in described coconut milk, carry out centrifugal concentration after mixing, wherein: the add-on of described sodium nitrite is 0.001% of coconut milk quality;

[0044] 3) Add monoglyceride, xanthan gum, maltodextrin, and glucose to the coconut milk after centrifugation and concentration in step 2), fully dissolve and mix to obtain emulsified coconut milk, wherein: the monoglyceride, xanthan gum The addition of raw gum, maltodextrin, and glucose are respectively 0.15%, 0.10%, 15%, and 4% of the mass of concentrated coconut milk;

[0045] 4) The emulsified ...

Embodiment 3

[0049] A kind of preparation method of coconut fragrance powder coconut oil of the present embodiment, described method specifically comprises the steps:

[0050] 1) Select fresh coconut meat without mildew and no rot, wash the coconut meat and crush it into shredded coconut, then squeeze the shredded coconut at a temperature of 50-75°C. pulp;

[0051] 2) get the coconut milk that 10kg step 1) obtains, and add citric acid in described coconut milk, carry out vacuum low-temperature concentration after mixing, wherein: the add-on of described citric acid is 0.10% of coconut milk quality;

[0052] 3) Add span60, carrageenan, maltodextrin, sucrose successively to the coconut milk after vacuum low temperature concentration in step 2), fully dissolve and mix to obtain emulsified coconut milk, wherein: the span60, carrageenan, malt paste The addition amount of essence and sucrose is respectively 0.06%, 0.50%, 30%, 6% of the mass of concentrated coconut milk;

[0053] 4) The emulsif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of repose | aaaaa | aaaaa |

| embedding rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com