Laser shock peening method for improving intensity of laser induced shock wave by adopting time sequence double laser pulse

A technology of laser shock strengthening and laser pulse, applied in the field of improving shock wave intensity and laser shock strengthening, can solve the problems of insufficient utilization of laser energy, affecting shock wave intensity, etc., to achieve the effect of increasing shock wave intensity, enhancing shock wave intensity, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

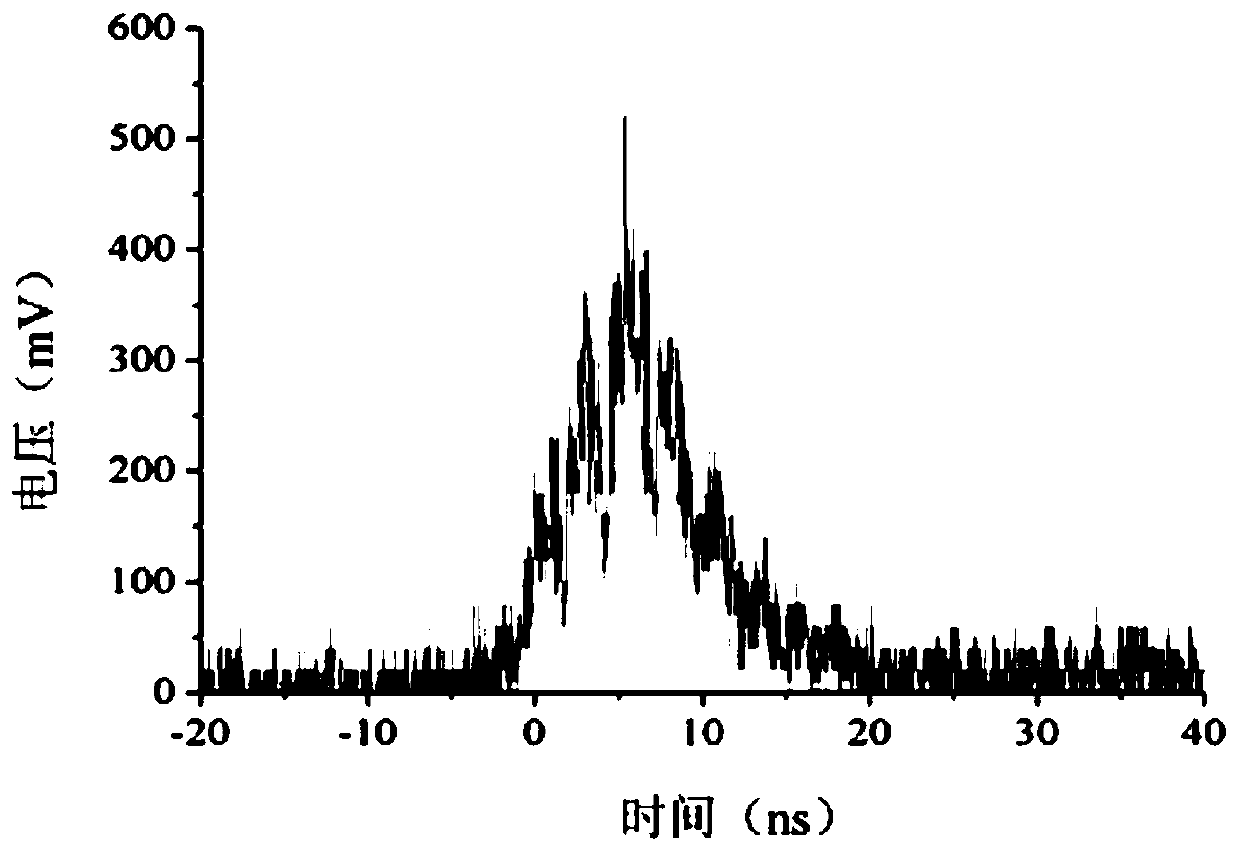

[0026] Embodiment 1: Laser pulse A and laser pulse B are split from the original single laser pulse. For the implementation device, see Figure 6 shown. Figure 1 (a), (b) is the original single laser pulse time waveform and laser spot of the laser used in the verification experiment supporting the present invention. The laser wavelength is 1064nm, the pulse width at half maximum is 12ns, the original spot diameter is 12mm, the total pulse energy is 680±10mJ, the laser spot irradiated to the surface of the workpiece is 1.2mm through lens convergence, and the laser power density is about 5GW / cm 2 .

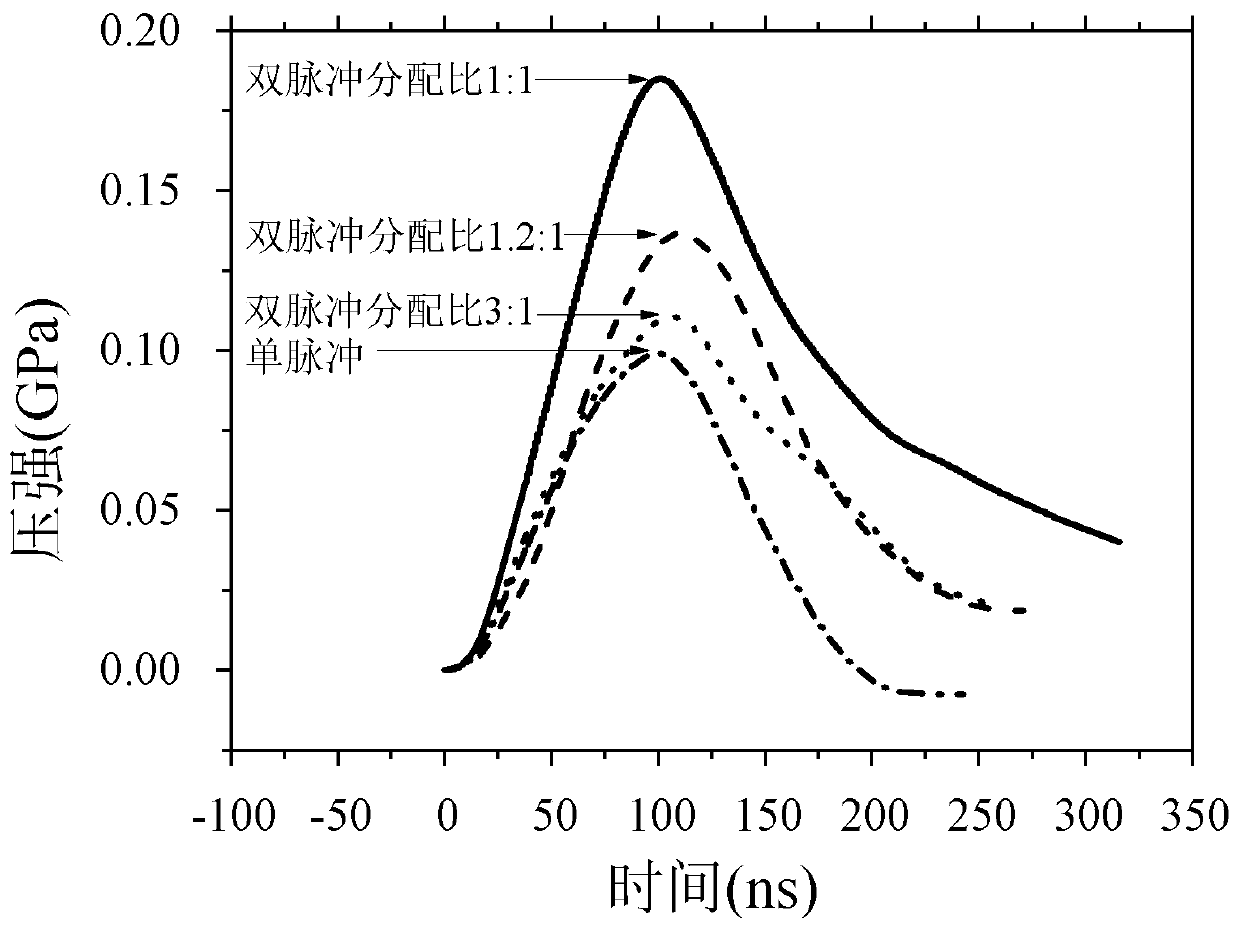

[0027] Based on the principle of laser-induced plasma detonation waves, the present invention utilizes the changing law of laser absorption characteristics of plasma during ignition and diffusion, and proposes a method of "splitting a single laser pulse and constructing time-sequential double pulses" to successively impact the workpiece, To achieve the purpose of increasing the sh...

Embodiment 2

[0036] Embodiment two: see Figure 7 As shown, laser pulse A and laser pulse B are output by two independent lasers. The specific process is as follows: two independent lasers are used to output two independent laser pulses that are relatively delayed under the control of a delay trigger: laser pulse A, laser pulse b. The delay trigger is implemented by a digital signal generator. After setting the delay amount, two independent pulse lasers are triggered successively to obtain two laser pulses in sequence.

[0037] Others are the same as in Embodiment 1.

Embodiment 3

[0038] Embodiment three: see Figure 8 As shown, the laser pulse train impact strengthening scheme extended from the basic idea and principle of the present invention, such as Figure 8 As shown, according to the needs of the actual process, constructing a time-sequential laser pulse train of more than two pulses and sequentially irradiating and impacting the surface of the workpiece can prolong the duration of the shock wave, increase the impulse, and increase the depth of the residual compressive stress of the workpiece. This is of great significance to laser shock peening engineering and technology. In the specific implementation process, the sub-pulse laser energy size and the time interval between sub-pulse can be set according to the control principle of the plasma electron density described in the present invention, so as to improve the laser energy utilization rate and prolong the duration of the shock wave. Effect.

[0039] The number of split single pulses is set a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com