Robust real-time weld joint feature detection method

A technology of welding seam characteristics and detection methods, which is applied in the field of automatic detection system of welding trajectory, and can solve problems such as performance constraints of welding seam detection system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

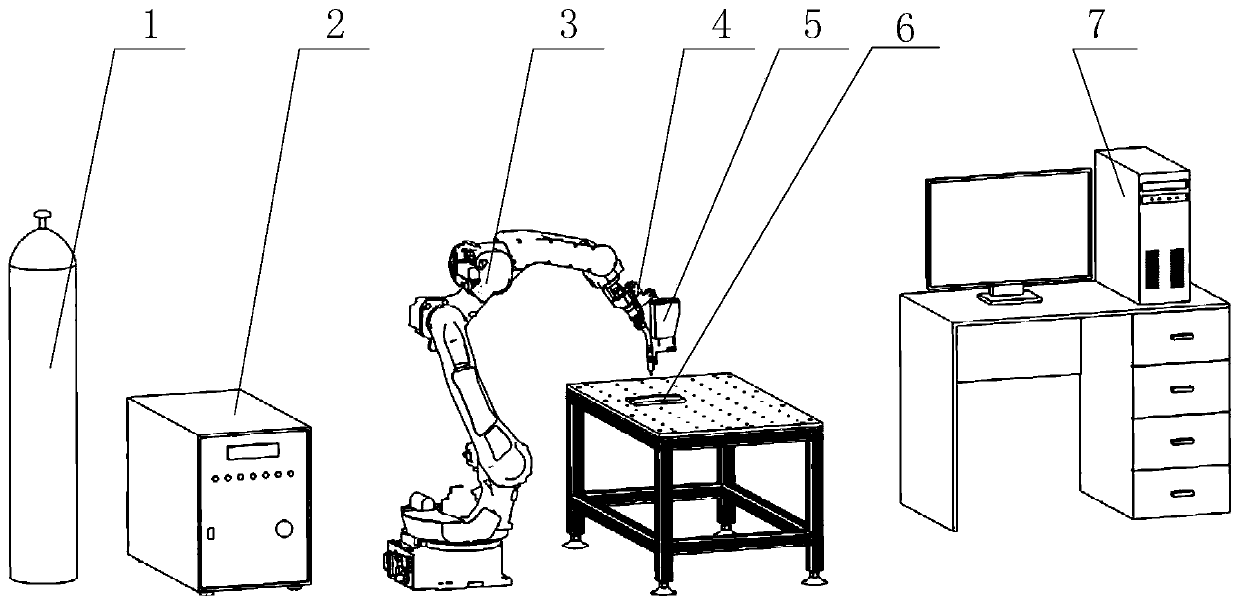

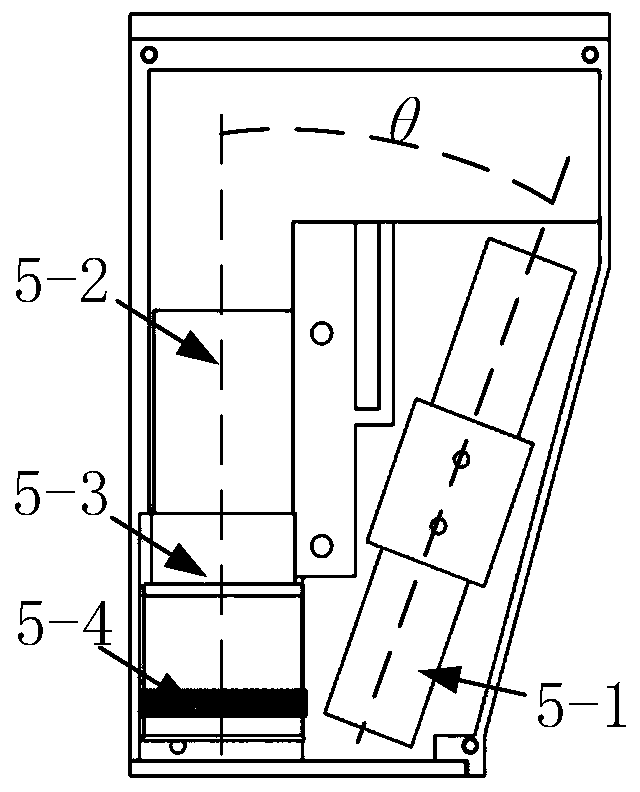

[0072] like figure 1 As shown, the laser vision weld seam detection system includes a welding protective gas cylinder 1, a multifunctional digital welding power supply 2, a six-axis welding robot 3, a sensor fixture 4, a laser vision sensor 5, a welding workpiece and a workbench 6, and an industrial control computer 7. like figure 2 As shown, the laser vision sensor 5 is composed of a laser 5-1, an industrial camera 5-2, a camera lens 5-3, and an optical filter 5-4. The laser 5-1 and the industrial camera 5-2 are installed at an angle of 20°. The laser vision sensor 5 is fixed and front-mounted on the front end of the welding torch through the sensor fixture 4, so as to realize real-time acquisition of weld seam features.

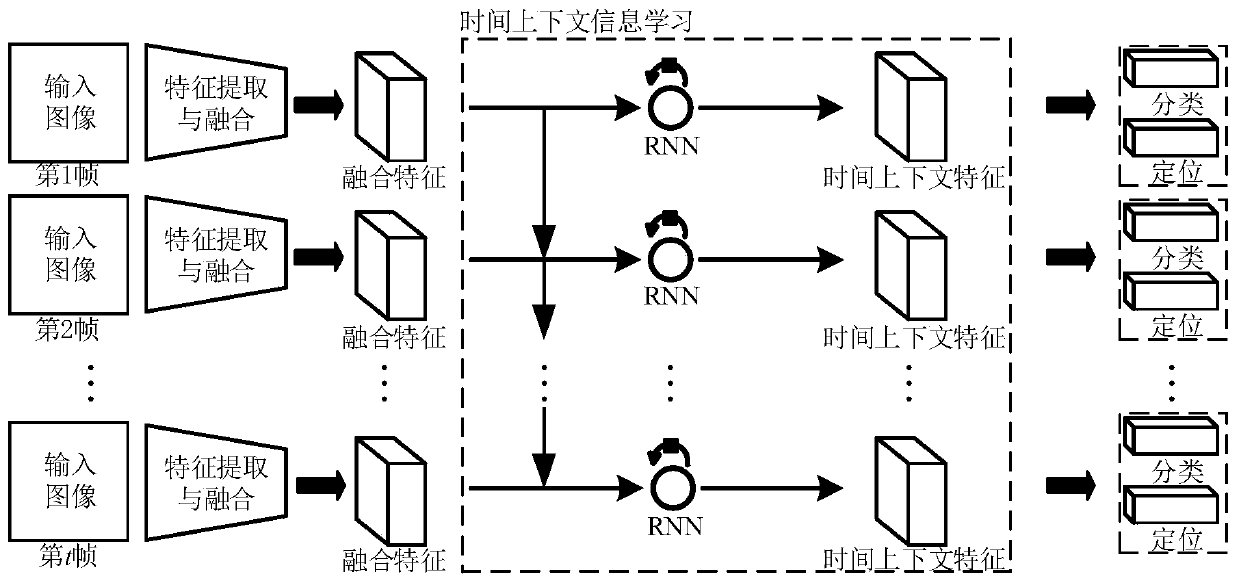

[0073] like image 3 As shown, the robust real-time weld feature detection method proposed in this embodiment realizes the detection of weld features in the images collected by the laser vision sensor 5, specifically including steps:

[0074] S1, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com