Silicon substrate cleaning method

A silicon substrate, water rinsing technology, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as poor, easy to corrode, destroying the cleaning effect of the oxide layer, etc., to achieve high uniformity, low cleaning cost, cleaning good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

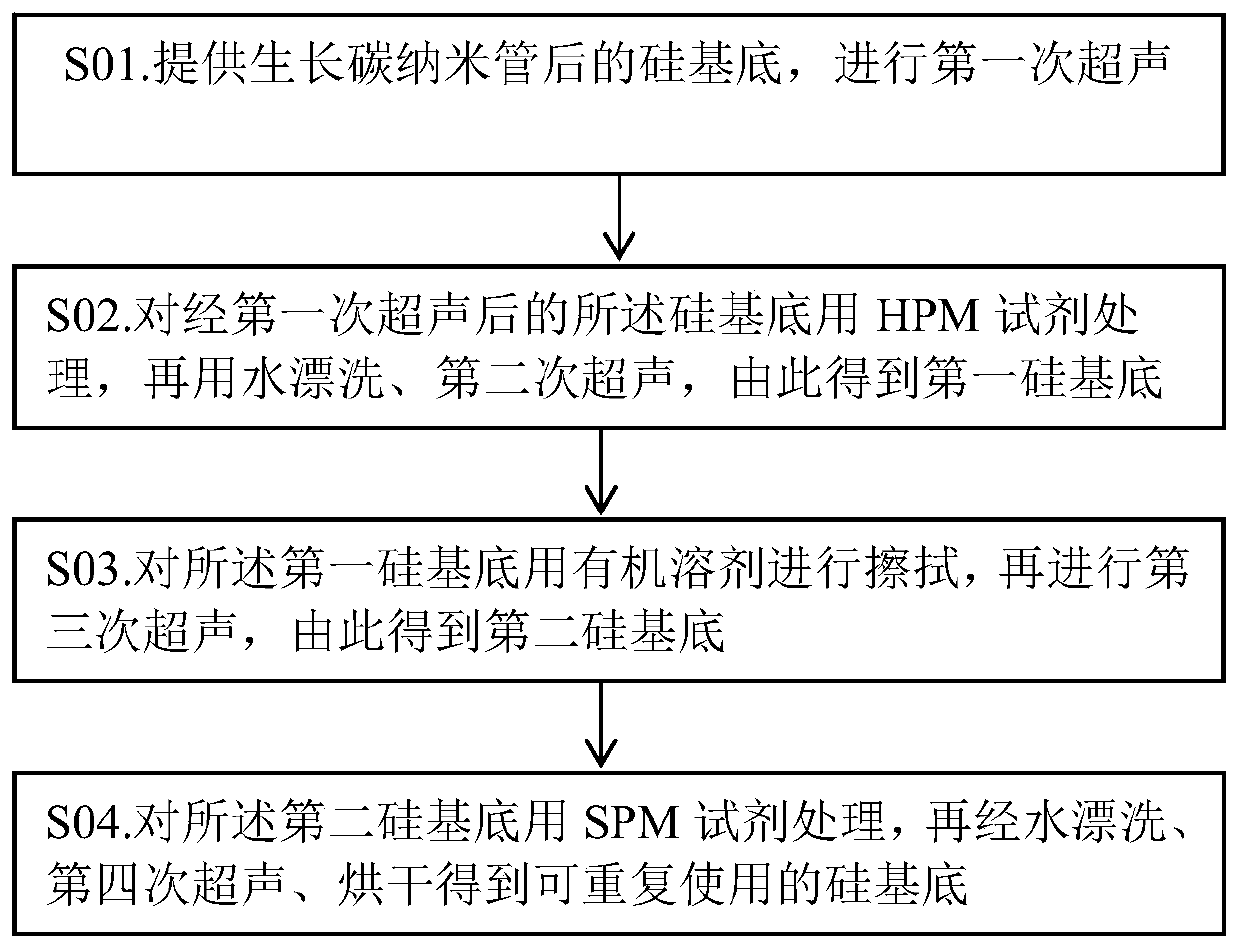

Method used

Image

Examples

Embodiment 1

[0034] Provide 50 pieces of silicon substrates grown by carbon nanotubes, and use pure water to sonicate for 5 minutes at a frequency of 40 Hz; place the flower basket containing silicon chips in a quartz boat containing HPM reagents, the temperature of the reagents is 70 ° C, soak for 15 minutes, The HPM reagent is a volume ratio of DIW: hydrogen peroxide: hydrochloric acid = 6:1:1; rinse the silicon wafer with pure water for 5 minutes, and then use pure water to sonicate at a frequency of 40 Hz for 5 minutes to remove excess impurities; use a class 100 dust-free Dip the cloth with absolute ethanol, gently wipe the surface of the silicon wafer, remove the carbon nanotubes and amorphous carbon attached to the silicon wafer, and prevent them from being carried into the next process, and then use pure water at a frequency of 40 Hz for 5 minutes; Place the flower basket of silicon wafers in a quartz boat with SPM reagent at a temperature of 110°C and soak for 15 minutes. The SPM r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com