Autoclaved aerated concrete block/slab containing novel mortar and preparation method

A technology of concrete block and autoclaved aeration, applied in the field of concrete blocks, can solve the problems of waste of resources, production process equipment, unstable bubbles, etc., and achieve the effects of good crystallinity, small drying shrinkage value, and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

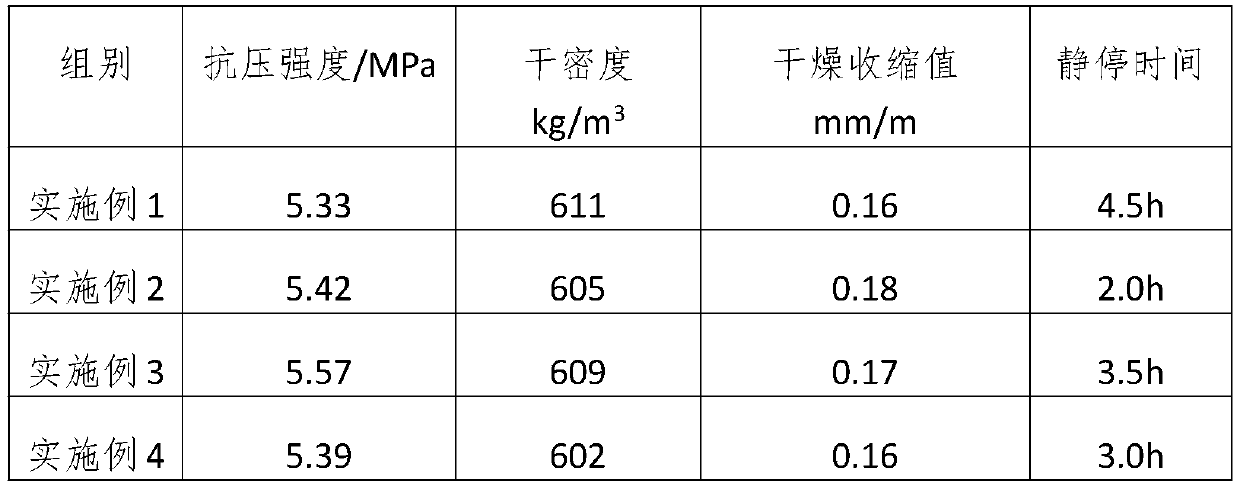

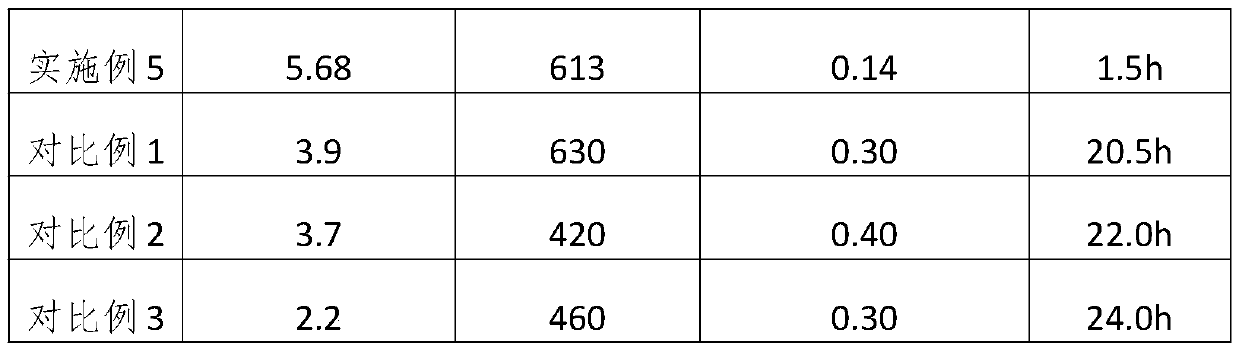

Embodiment 1

[0049] An autoclaved aerated concrete block / board containing a new type of mortar, made of the following raw materials in weight percentage: 47% of silicon material, 8% of new type of mortar, 8% of lime, 5% of aluminum powder paste, and the balance is waste The new mortar is made of the following raw materials in parts by weight: 95 parts of cement clinker, 25 parts of magnesium phosphate cement, and 2 parts of hemihydrate gypsum.

[0050] Further, the fineness of the new mortar is capable of passing through a 75 μm square hole sieve, the initial and final setting times are 70 minutes, and the effective CaO content is >63%; the siliceous material is sand or fly ash; the sand is silica sand , mud content 75%; the fly ash is solid waste after coal combustion in thermal power plants; the lime is quicklime, and its effective calcium oxide content is greater than 70%; the aluminum powder The plaster meets the following conditions: solid content ≥ 65%, active aluminum ≥ 85%, finene...

Embodiment 2

[0066] An autoclaved aerated concrete block / board containing a new type of mortar, made of the following raw materials in weight percentage: 77% of silicon material, 15% of new type of mortar, 15% of lime, 25% of aluminum powder paste, and the balance is waste The new mortar is made of the following raw materials in parts by weight: 120 parts of cement clinker, 40 parts of magnesium phosphate cement, and 8 parts of hemihydrate gypsum.

[0067] Further, the fineness of the new mortar is capable of passing through a 85 μm square hole sieve, the initial and final setting times are 140 minutes, and the effective CaO content is >63%; the siliceous material is sand or fly ash; the sand is silica sand , mud content 75%; the fly ash is solid waste after coal combustion in thermal power plants; the lime is quicklime, and its effective calcium oxide content is greater than 70%; the aluminum powder The plaster meets the following conditions: solid content ≥ 65%, active aluminum ≥ 85%, f...

Embodiment 3

[0083] An autoclaved aerated concrete block / board containing a new type of mortar, made of the following raw materials in weight percentage: siliceous material 50%, new type mortar 9%, lime 9%, aluminum powder paste 10%, and the balance is waste The new mortar is made of the following raw materials in parts by weight: 100 parts of cement clinker, 30 parts of magnesium phosphate cement, and 3 parts of hemihydrate gypsum.

[0084] Further, the fineness of the new mortar is such that it can pass through a 78 μm square hole sieve, the initial and final setting times are 80 minutes, and the effective CaO content is >63%; the siliceous material is sand or fly ash; the sand is silica sand , mud content 75%; the fly ash is solid waste after coal combustion in thermal power plants; the lime is quicklime, and its effective calcium oxide content is greater than 70%; the aluminum powder The plaster meets the following conditions: solid content ≥ 65%, active aluminum ≥ 85%, fineness 0.075...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com