Water-based two-component bright white finish preventing rash and preparation process thereof

A water-based two-component, white topcoat technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of easy heat rash and pinholes, poor overall application effect, etc., and achieve good smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

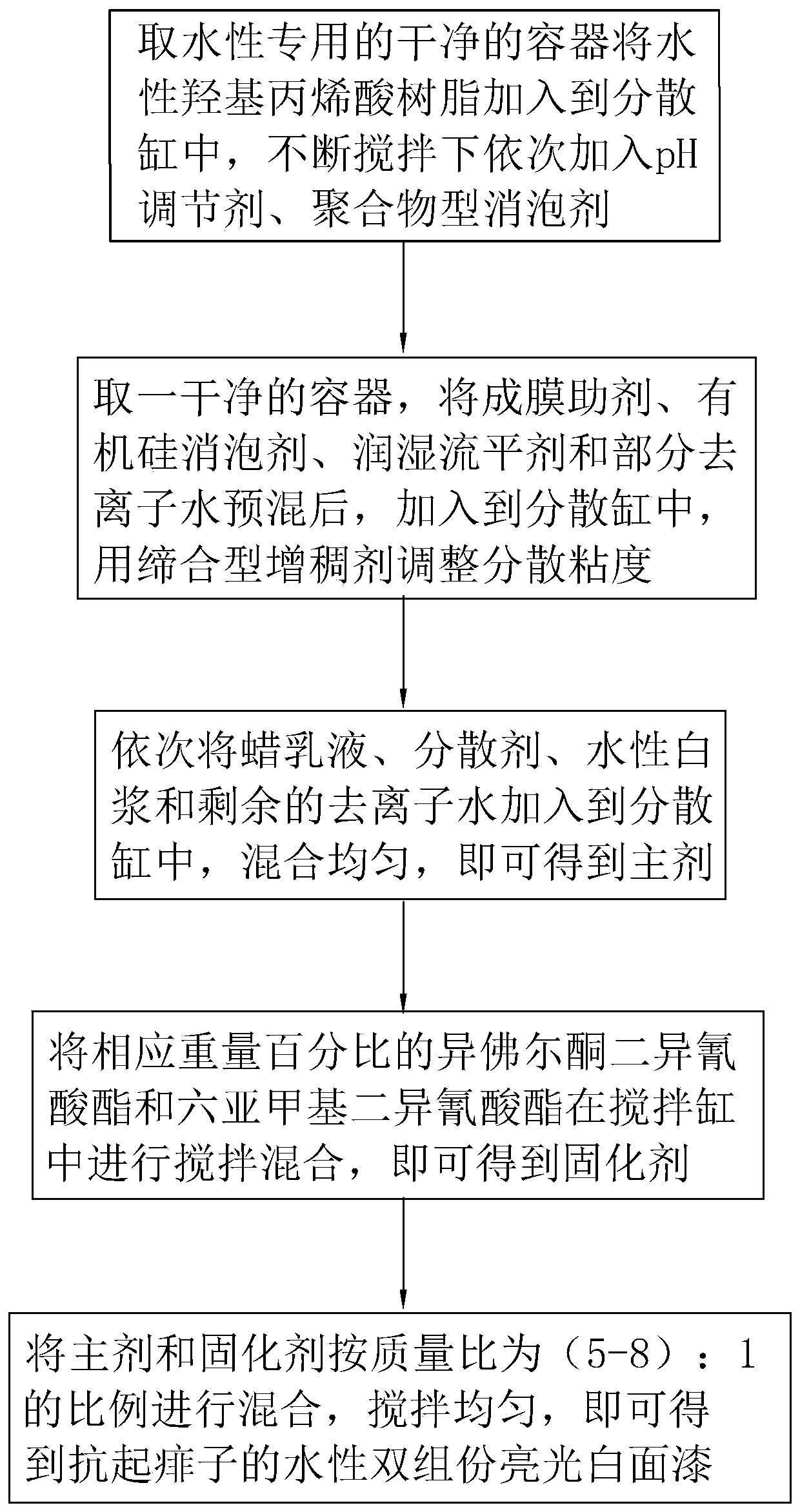

[0054] Embodiment 1-3: a water-based two-component glossy white topcoat that resists prickly heat, and is prepared through the following steps:

[0055] Step 1: Take a clean water-based special container and add water-based hydroxyacrylic resin into the dispersing tank, start the dispersing machine, add calcium hydroxide and polymer-type defoamer in turn at 650r / min, and adjust the speed to 1050r / min min, high-speed dispersion for 30 minutes, QC detection of 100 micron cardboard without shrinkage and particles;

[0056] Step 2, take a clean container, pre-mix propylene glycol butyl ether, silicone defoamer, wetting and leveling agent and part of deionized water, add it to the dispersion cylinder at a flow rate of 2.5kg / min, and adjust the speed to 1100r / min, adjust dispersion viscosity with associative thickener, disperse at high speed for 25 minutes, QC test fineness <30, draw plate without shrinkage cavity;

[0057] Step 3: Add the wax emulsion, polyacrylamide, water-based ...

Embodiment 4

[0061] Example 4: A water-based two-component bright white finish that resists prickly heat. The difference from Example 1 is that step 5 is specifically set as follows: the ratio of the main agent and the curing agent is 5:1 by mass Mix at a stirring speed of 1000r / min for 20 minutes to obtain a water-based two-component bright white finish that resists prickly heat.

Embodiment 5

[0062] Example 5: A water-based two-component glossy white finish that resists prickly heat. The difference from Example 1 is that step 5 is specifically set as that the main agent and the curing agent are in a mass ratio of 8:1 Mix at a stirring speed of 1000r / min for 20 minutes to obtain a water-based two-component bright white finish that resists prickly heat.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com