A Design Method for Thin Shell Acoustic Superstructures with Arbitrary Surface Shape

A design method and technology of thin shell structure, applied in the direction of sound-producing equipment, instruments, etc., can solve problems such as lack of design methods, and achieve the effect of reducing environmental noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0049] (1) Broadband ultra-strong sound insulation thin shell structure design

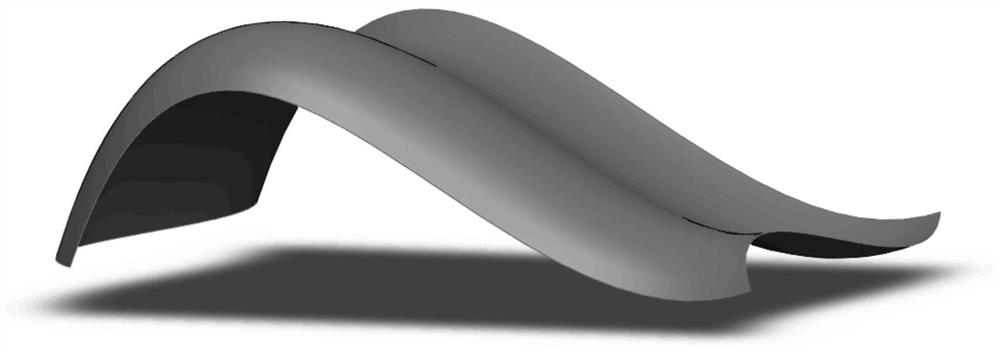

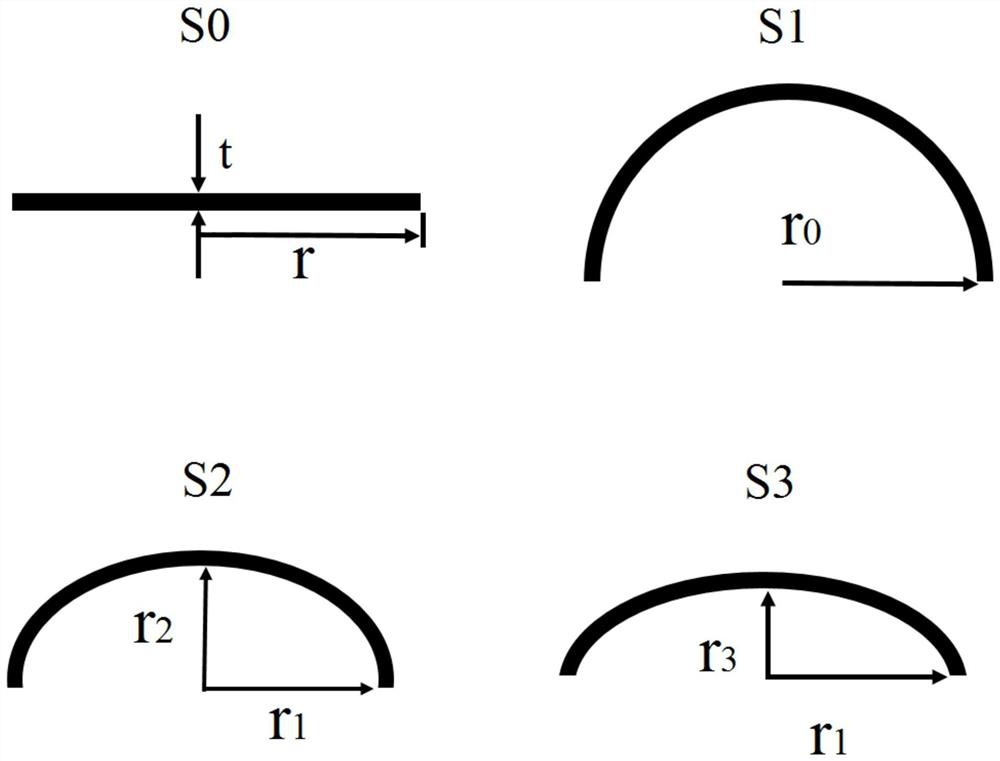

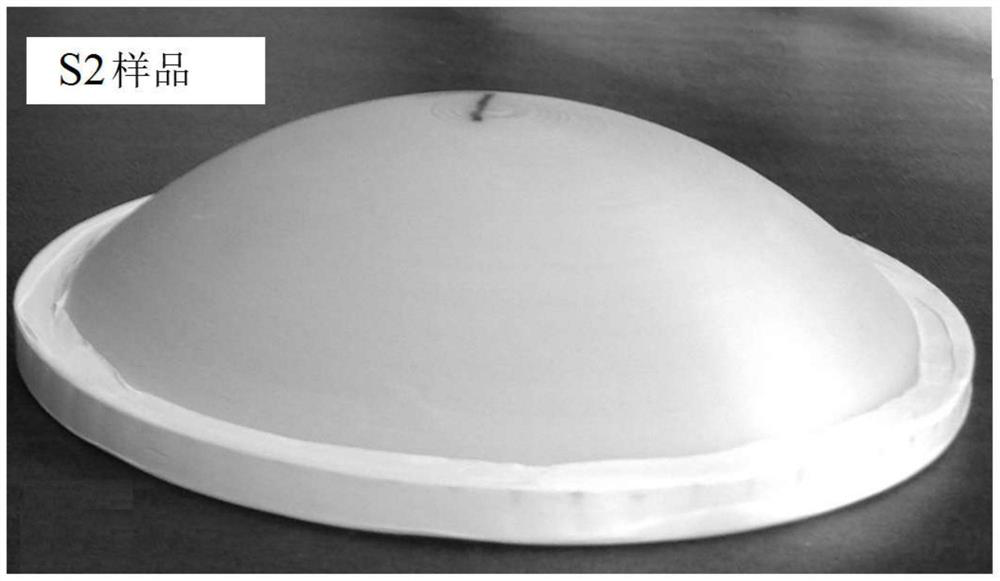

[0050] Thin-shell structures are the most commonly used thin-walled structures in engineering. Commonly used thin-shell structures include rotating shells and cylindrical shells, or many structures are complex curved shell structures that are compounded or evolved from these two types of structures, such as attached figure 1 shown. Among the two commonly used thin shell structures, cylindrical shells are more widely used than rotary shells. However, considering that the cylindrical shell structure is not convenient for acoustic performance measurement, the present invention first designs a rotating shell structure for experimental verification. For comparison, two sets of structures (S0 and S1) of thin plate and hemispherical rotating shell were designed respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com