Bismuth oxide/bismuthyl carbonate/bismuth molybdate composite photocatalytic material and preparation method thereof

A technology of composite photocatalysis and photocatalytic materials, which is applied in the field of industrial catalytic preparation, can solve the problem of low visible light catalytic activity of bismuth molybdate, and achieve the effects of wide visible light response range, convenient operation and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

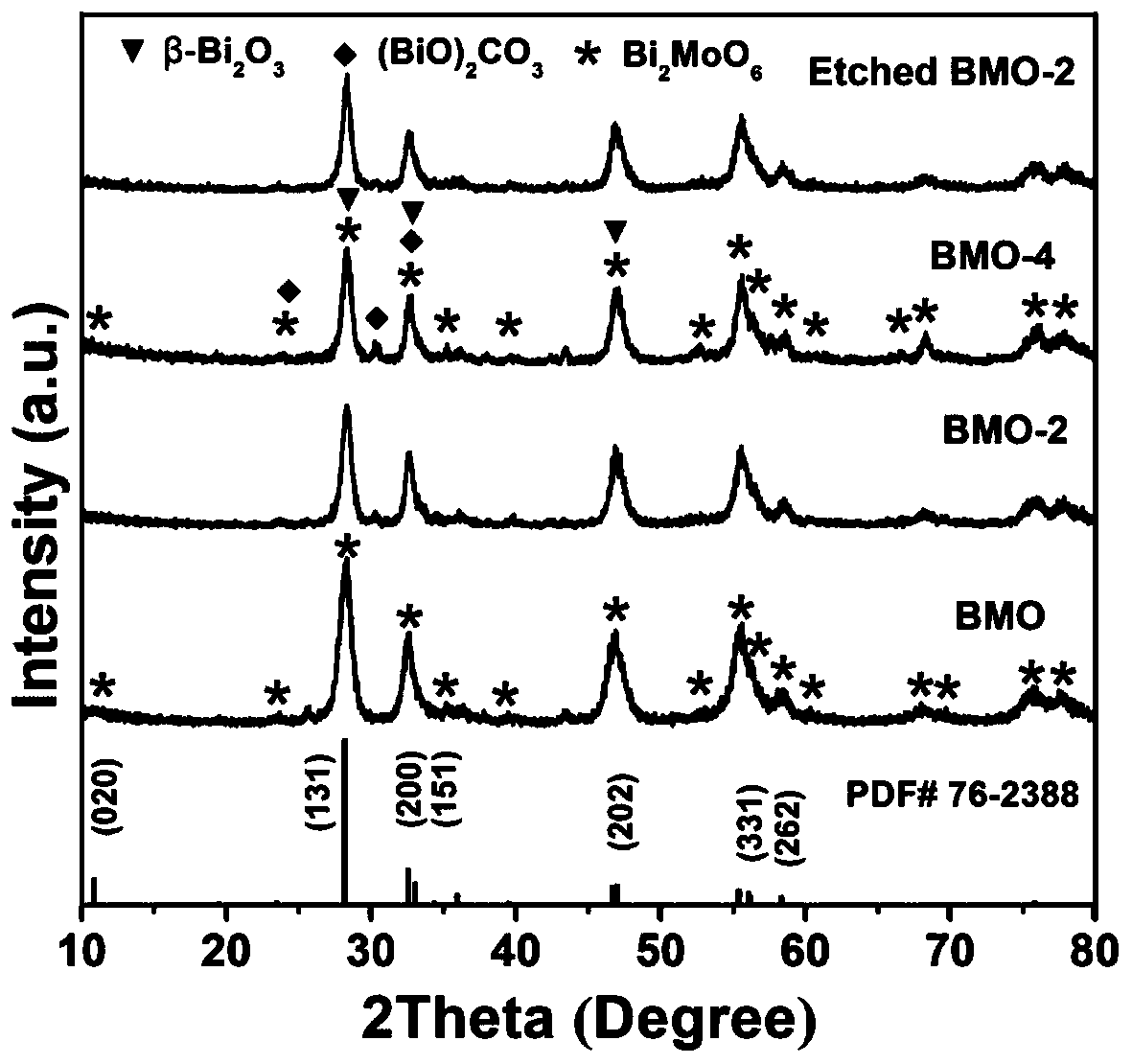

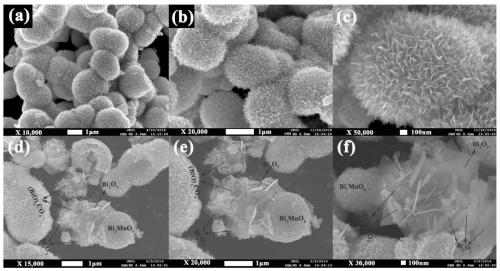

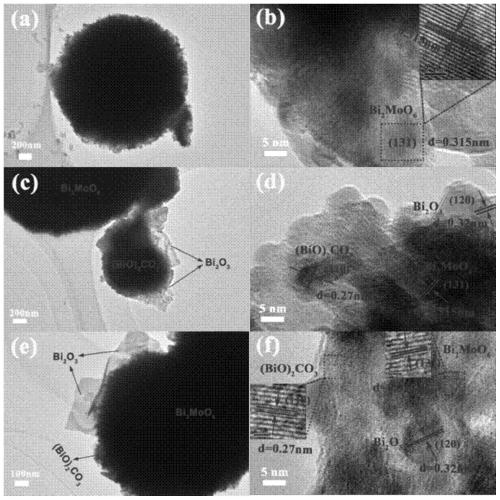

[0041] A kind of preparation method of above-mentioned bismuth oxide / bismuth oxycarbonate / bismuth molybdate composite photocatalytic material of the present invention, specifically implement according to the following steps:

[0042] Step 1.1, measure Bi(NO 3 ) 3 ·5H 2 O and Na 2 MoO 4 2H 2 O, the measured Bi(NO 3 ) 3 ·5H 2 O was dissolved in ethylene glycol solution, and then a measure of Na was added to the ethylene glycol solution 2 MoO 4 2H 2 O, finally stir until a transparent solution is obtained;

[0043] Step 1.2, first add absolute ethanol to the transparent solution obtained in step 1.1 and stir evenly, then transfer it to a stainless steel reaction kettle lined with Teflon and seal it, and then put the reaction kettle into the electric heating constant temperature blast In a drying oven, react at 160°C for 12 hours to obtain a mixed solution A. After the reaction is completed, the mixed solution A is naturally cooled to room temperature, then centrifuged,...

Embodiment 2

[0048] A kind of preparation method of above-mentioned bismuth oxide / bismuth oxycarbonate / bismuth molybdate composite photocatalytic material of the present invention, specifically implement according to the following steps:

[0049] Step 1.1, measure Bi(NO 3 ) 3 ·5H 2 O and Na 2 MoO 4 2H 2 O, the measured Bi(NO 3 ) 3 ·5H 2 O was dissolved in ethylene glycol solution, and then a measure of Na was added to the ethylene glycol solution 2 MoO 4 2H 2 O, finally stir until a transparent solution is obtained;

[0050] Step 1.2, first add absolute ethanol to the transparent solution obtained in step 1.1 and stir evenly, then transfer it to a stainless steel reaction kettle lined with Teflon and seal it, and then put the reaction kettle into the electric heating constant temperature blast In a drying oven, react at 160°C for 12 hours to obtain a mixed solution A. After the reaction is completed, the mixed solution A is naturally cooled to room temperature, then centrifuged,...

Embodiment 3

[0055] A kind of preparation method of above-mentioned bismuth oxide / bismuth oxycarbonate / bismuth molybdate composite photocatalytic material of the present invention, specifically implement according to the following steps:

[0056] Step 1.1, measure Bi(NO 3 ) 3 ·5H 2 O and Na 2 MoO 4 2H 2 O, the measured Bi(NO 3 ) 3 ·5H 2 O was dissolved in ethylene glycol solution, and then a measure of Na was added to the ethylene glycol solution 2 MoO 4 2H 2 O, finally stir until a transparent solution is obtained;

[0057] Step 1.2, first add absolute ethanol to the transparent solution obtained in step 1.1 and stir evenly, then transfer it to a stainless steel reaction kettle lined with Teflon and seal it, and then put the reaction kettle into the electric heating constant temperature blast In a drying oven, react at 160°C for 12 hours to obtain a mixed solution A. After the reaction is completed, the mixed solution A is naturally cooled to room temperature, then centrifuged,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com