Co/V double-metal-doped g-C3N4 photocatalyst and preparation method and application thereof

A photocatalyst, g-c3n4 technology, applied in physical/chemical process catalysts, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as limited performance improvement and reduced carrier separation efficiency, and achieve The effect of short reaction time, increasing surface active sites, and improving degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

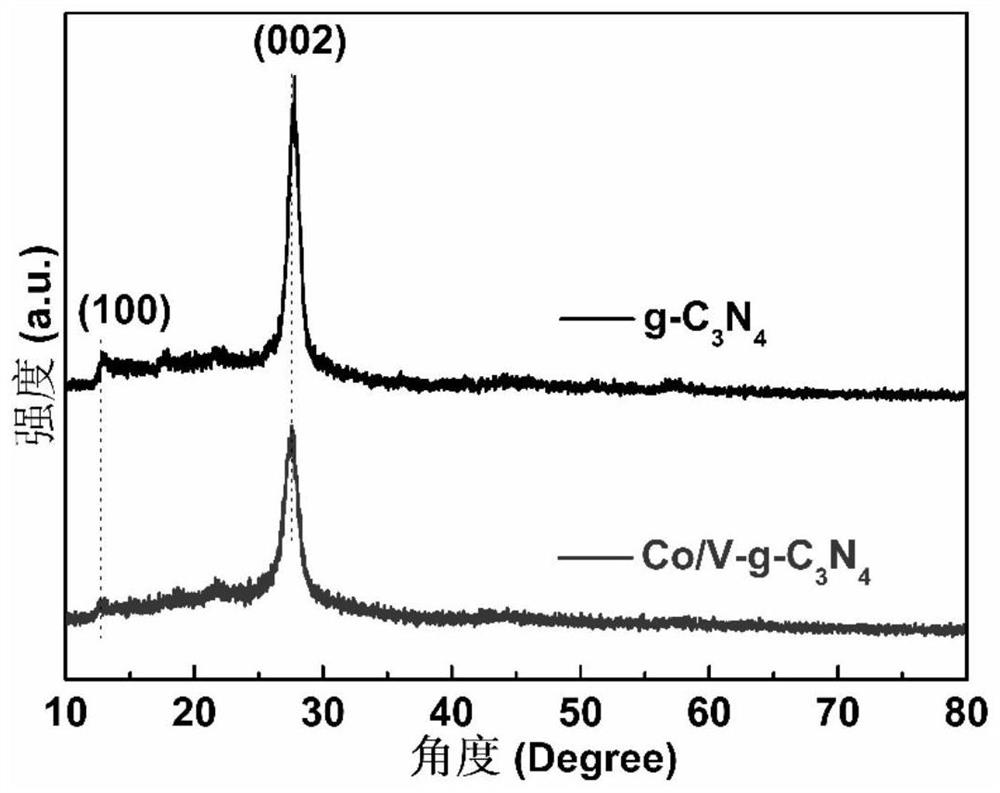

[0036] Example 1: Co / V double metal doping g-C3 N 4 Preparation of photocatalyst

[0037] (1) Co / V double metal doped g-C 3 N 4 Preparation of photocatalyst precursor:

[0038] Prepare 0.1mol L -1 DMF solution containing vanadyl acetylacetonate, 0.2mol L -1 Cobalt acetate aqueous solution, set aside; then dissolve 1g urea in 5mL distilled water, stir well, then add 5mL cobalt acetate aqueous solution, 20mL DMF solution containing vanadyl acetylacetonate to it, mix well, transfer the mixed solution to high pressure Heat reaction at 150°C for 24 hours in the reaction kettle, cool to room temperature after the reaction, centrifuge, wash, and dry to obtain Co / V bimetallic doped g-C 3 N 4 Photocatalyst precursor;

[0039] (2) Co / V double metal doped g-C 3 N 4 Preparation of photocatalyst:

[0040] 10g of urea dried at 80°C for 24h, 0.001g of Co / V bimetallic doped g-C 3 N 4 The photocatalyst precursors were mixed evenly, ground and transferred to a crucible, and placed i...

Embodiment 2

[0044] Example 2: Co / V double metal doping g-C 3 N 4 Preparation of photocatalyst

[0045] (1) Co / V double metal doped g-C 3 N 4 Preparation of photocatalyst precursor:

[0046] Prepare 0.1mol L -1 DMF solution containing vanadyl acetylacetonate, 0.2mol L -1 Cobalt acetate aqueous solution, set aside; then dissolve 1g urea in 5mL distilled water, stir well, then add 5mL cobalt acetate aqueous solution, 20mL DMF solution containing vanadyl acetylacetonate to it, mix well, transfer the mixed solution to high pressure Heat reaction at 150°C for 24 hours in the reaction kettle, cool to room temperature after the reaction, centrifuge, wash, and dry to obtain Co / V bimetallic doped g-C 3 N 4 Photocatalyst precursor;

[0047] (2) Co / V double metal doped g-C 3 N 4 Preparation of photocatalyst:

[0048] 10g of urea dried at 80°C for 24h, 0.0025g of Co / V bimetallic doped g-C 3 N 4 The photocatalyst precursors were mixed evenly, ground and transferred to a crucible, and place...

Embodiment 3

[0050] Example 3: Co / V double metal doping g-C 3 N 4 Preparation of photocatalyst

[0051] (1) Co / V double metal doped g-C 3 N 4 Preparation of photocatalyst precursor:

[0052] Prepare 0.1mol L -1 DMF solution containing vanadyl acetylacetonate, 0.2mol L -1 Cobalt acetate aqueous solution, set aside; then dissolve 1g urea in 5mL distilled water, stir well, then add 5mL cobalt acetate aqueous solution, 20mL DMF solution containing vanadyl acetylacetonate to it, mix well, transfer the mixed solution to high pressure Heat reaction at 150°C for 24 hours in the reaction kettle, cool to room temperature after the reaction, centrifuge, wash, and dry to obtain Co / V bimetallic doped g-C 3 N 4 Photocatalyst precursor;

[0053] (2) Co / V double metal doped g-C 3 N 4 Preparation of photocatalyst:

[0054] 10g of urea dried at 80°C for 24h, 0.005g of Co / V bimetallic doped g-C 3 N 4 The photocatalyst precursors were mixed evenly, ground and transferred to a crucible, and placed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com