Preparation method for 3D morphological silver/silver bromide/titanium dioxide photocatalyst and product and application thereof

A photocatalyst and morphology technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems that the large specific surface area 3D morphology Ag/AgBr/TiO2 preparation method has not been reported. , to achieve the effect of broadening the visible light response range, increasing the specific surface area, and increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

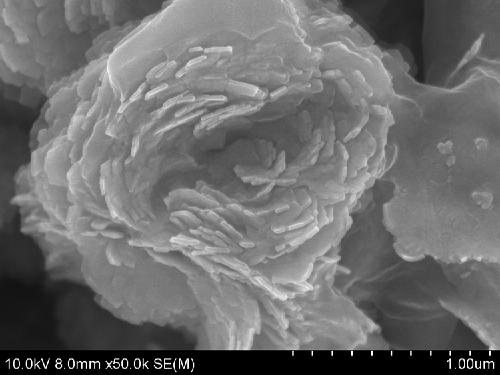

Image

Examples

Embodiment 1

[0034] First, mix isopropyl titanate or tetrabutyl titanate and concentrated hydrochloric acid and stir evenly, the molar ratio of titanate and hydrochloric acid is 1:50; add cetyltrimethylammonium bromide in deionized water (CTAB), mix and stir well. The CTAB aqueous solution was added dropwise to the titanate solution and stirred for 1 h. The molar ratio of titanate and CTAB is 1:0.5, and the molar ratio of titanate and water is 1:2000. A certain amount of ethylene glycol and urea were respectively added to the above mixed solution of titanate and CTAB, and stirred evenly. The molar ratio of titanate and ethylene glycol is 1:1000, and the molar ratio of titanate and urea is 1:20. The above mixed solution was added into a 100mL hydrothermal kettle, and subjected to a hydrothermal reaction at 150°C for 24 hours to generate titanium dioxide with a 3D morphology. Add silver nitrate and 2mL ammonia water to the suspension containing 3D titanium dioxide obtained by hydrothermal...

Embodiment 2

[0037]First, titanate (isopropyl titanate or tetrabutyl titanate) and concentrated hydrochloric acid are mixed and stirred evenly. The molar ratio of titanate and hydrochloric acid is 1:100. Add cetyltrimethylammonium bromide (CTAB) to deionized water, mix and stir well. The CTAB aqueous solution was added dropwise to the titanate solution and stirred for 1 h. The molar ratio of titanate and CTAB is 1:1, and the molar ratio of titanate and water is 1:1000. A certain amount of ethylene glycol and urea were respectively added to the above mixed solution of titanate and CTAB, and stirred evenly. The molar ratio of titanate and ethylene glycol is 1:2000, and the molar ratio of titanate and urea is 1:20. The above mixed solution was added into a 100mL hydrothermal kettle, and subjected to a hydrothermal reaction at 150°C for 24 hours to generate titanium dioxide with a 3D morphology. Add silver nitrate and 2mL ammonia water to the suspension containing 3D titanium dioxide obtain...

Embodiment 3

[0040] First, titanate (isopropyl titanate or tetrabutyl titanate) and concentrated hydrochloric acid are mixed and stirred evenly. The molar ratio of titanate and hydrochloric acid is 1:200. Add cetyltrimethylammonium bromide (CTAB) to deionized water, mix and stir well. The CTAB aqueous solution was added dropwise to the titanate solution and stirred for 1 h. The molar ratio of titanate and CTAB is 1:1, and the molar ratio of titanate and water is 1:2000. A certain amount of ethylene glycol and urea were respectively added to the above mixed solution of titanate and CTAB, and stirred evenly. The molar ratio of titanate and ethylene glycol is 1:2000, and the molar ratio of titanate and urea is 1:40. The above mixed solution was added into a 100mL hydrothermal kettle, and subjected to a hydrothermal reaction at 150°C for 12h to generate titanium dioxide with a 3D morphology. Add silver nitrate and 2mL ammonia water to the suspension containing 3D titanium dioxide obtained b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com