Regulating and controlling method for localized surface plasmons of copper selenide nanoparticles

A localized surface plasmon and nanoparticle technology, applied in the field of electric variable adjustment and control, can solve the problems of quantitative difficulty, lack of dynamic reversibility, unclear carrier control mechanism, etc., and achieve simple electrode preparation process and good cycle stability Good performance, regulation and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

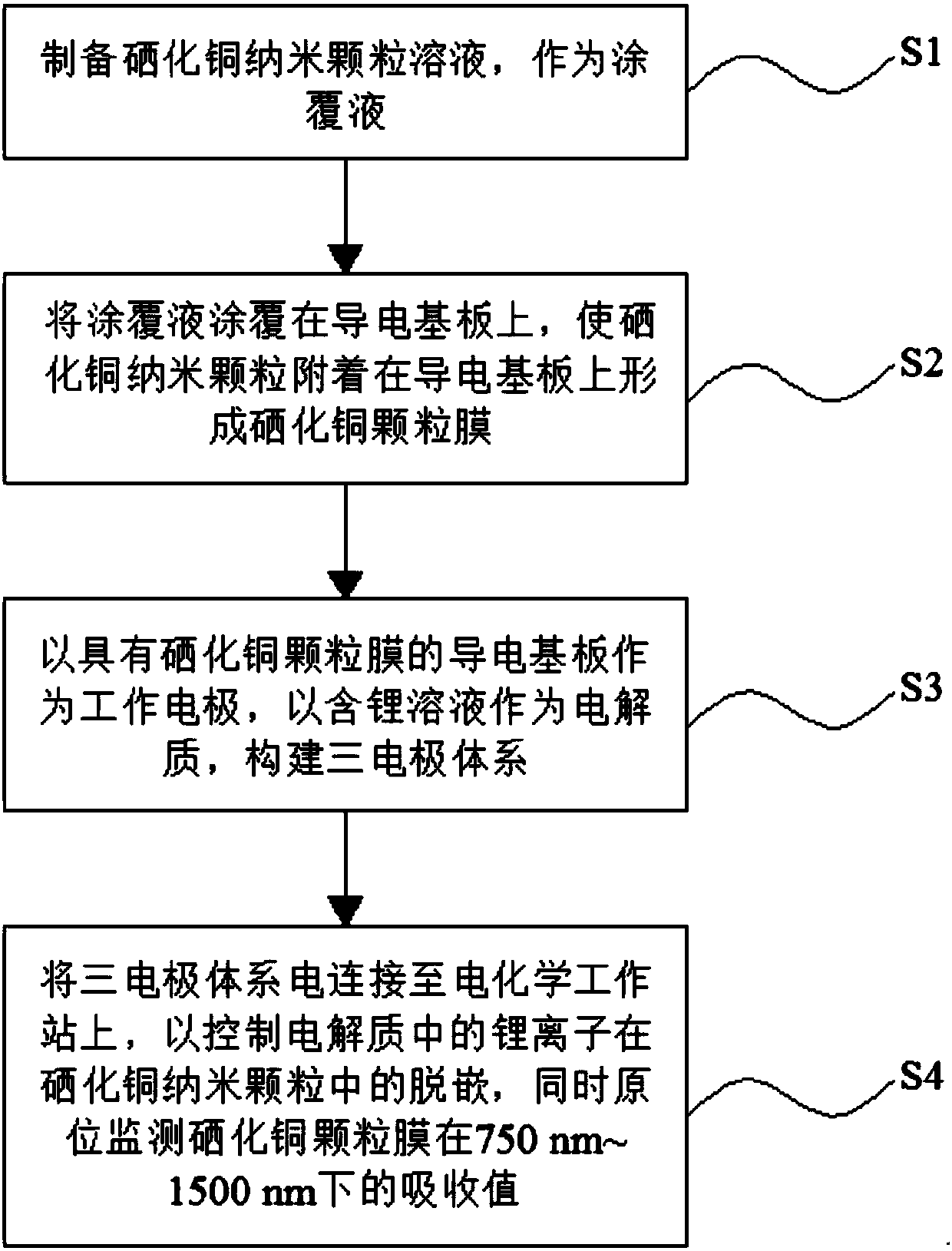

[0072] In this embodiment, Cu 2-x The regulation method of Se LSPR refers to the following steps:

[0073] Step A, prepare Cu 2-x Se solution is used as the coating liquid.

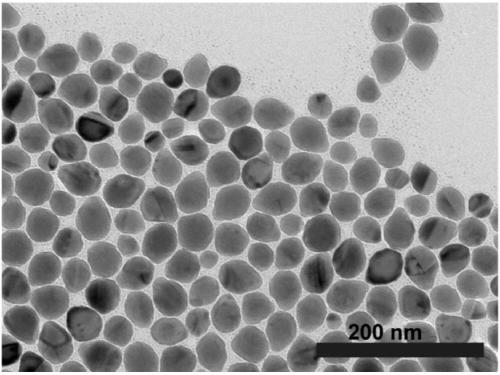

[0074] Specifically, (1) Add 32 mL of 10 mg / mL sodium dodecyl sulfate (SDS) solution to 110 mL of water at 30°C and mix well to obtain solution 1; (2) Weigh 44.4 mg of selenium dioxide (SeO 2 ) SeO is obtained after dissolving in 2mL water by ultrasonic 2 Dispersion liquid, and the SeO 2 Add the dispersion to Solution 1 and mix well to obtain Solution 2; (3) Weigh 422.7 mg of ascorbic acid (AA) in 6 mL of water, dissolve it ultrasonically, add it to Solution 2 under magnetic stirring, and react for 10 minutes to obtain a colloid; (4) ) Weigh 563.6mg AA in 8mL water, and weigh 200mg copper sulfate pentahydrate (CuSO 4 ·5H 2 O) Dissolve in 2mL of water, mix by ultrasonic, add to the colloid, stir magnetically for 12h to obtain Cu 2-x Se colloidal solution; (5) Cu 2-x The Se colloidal solution was centrifuged at ...

Embodiment 2

[0086] In the description of Embodiment 2, the similarities to Embodiment 1 will not be repeated here, and only the differences from Embodiment 1 will be described. The difference between Embodiment 2 and Embodiment 1 is:

[0087] In step A, the following method is used to prepare Cu 2-x The Se solution was used as the coating liquid.

[0088] (1) Add 32mL of 10mg / mL SDS solution to 110mL of water at 30°C and mix well to obtain solution 1; (2) Weigh 986.3mg of AA in 14mL of water and dissolve it by ultrasound to obtain solution 2; (3) Add solution 2 to solution 1 and mix well to obtain the first mixed solution; (4) Weigh 200mg CuSO 4 ·5H 2 O was dissolved in 2 mL of water and added to the first mixed solution after being ultrasonically dissolved and mixed to obtain the second mixed solution; (5) Weigh 44.4 mg of SeO 2 Dissolve in 2mL water and obtain SeO after ultrasonic 2 Dispersion liquid, and the SeO 2 The dispersion liquid is added to the second mixed liquid under magnetic stir...

Embodiment 3

[0095] In the description of Embodiment 3, the similarities with Embodiment 1 will not be repeated here, and only the differences from Embodiment 1 will be described. The difference between Example 3 and Example 1 is:

[0096] In step A, the following method is used to prepare Cu 2-x The Se solution was used as the coating liquid.

[0097] (1) Weigh 5.5mg SeO at 30℃ 2 SeO is obtained after dissolving in 0.5mL water by ultrasonic 2 Dispersion liquid, and the SeO 2 The dispersion was added to 8mL of 10mg / mL SDS solution, magnetically stirred to obtain a mixed solution; (2) Weigh 52.8mg AA in 1.5mL of water, dissolve it ultrasonically, add it to the mixed solution, react for 10 minutes to obtain the first colloid; (3) Take 2mL of the first colloid and place it in 1.5mL of 42mg / mL SDS solution, magnetically stir to obtain the second colloid; (4) Weigh 5.5mg of SeO 2 And 52.8mg AA in 3.5mL water respectively, after ultrasonic dissolving, add to the second colloid through a peristaltic p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com