Modified PVC cable material and preparation method thereof

A technology of cable material and PVC resin, which is applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., which can solve the problems of short service life, low volume resistivity, high temperature resistance, low temperature resistance, flame retardancy and poor insulation And other problems, to achieve the effect of improving wear resistance, excellent comprehensive performance, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

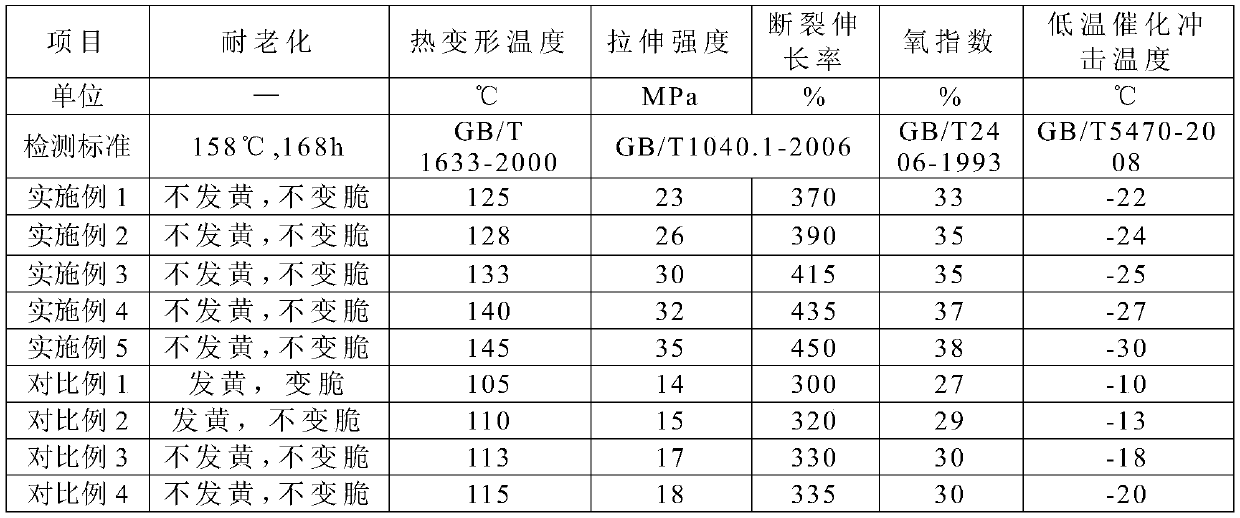

Examples

Embodiment 1

[0023] A modified PVC cable material, made of the following raw materials: 60 parts by weight of PVC resin, 15 parts of fluorine-containing boron ferrocene ring-based copolymer, 3 parts of ultra-high molecular weight polyethylene fiber, 6 parts of amino-terminated polyurethane, powder 5 parts of coal ash, 2 parts of oxidized paraffin, 5 parts of waste tire powder, 0.5 parts of silane coupling agent KH550.

[0024] Wherein, the fluorine-containing boron ferrocene ring-based copolymer is composed of 2-cyano-3-(pyridine-2-amino)-ethyl acrylate, E-2-[3,5-bis(trifluoromethyl) Phenyl] vinyl boronic acid pinacol ester, ene adenine and methyl vinyl [1] silaferrocene ring are produced by copolymerization.

[0025] The preparation method of the fluorine-containing boron ferrocene ring-based copolymer includes the following steps: 1 kg of 2-cyano-3-(pyridine-2-amino)-ethyl acrylate, E-2-[3,5-di (Trifluoromethyl)phenyl)vinylboronic acid pinacol ester 2kg, adenine 1kg, methylvinyl[1]silica fer...

Embodiment 2

[0029] A modified PVC cable material made of the following raw materials: 65 parts by weight of PVC resin, 18 parts of fluorine-containing boron ferrocene ring-based copolymer, 4.5 parts of ultra-high molecular weight polyethylene fiber, 7.5 parts of amino-terminated polyurethane, powder 6.5 parts of coal ash, 3.5 parts of oxidized paraffin, 6.5 parts of waste tire powder, 0.7 parts of silane coupling agent KH560.

[0030] Wherein, the fluorine-containing boron ferrocene ring-based copolymer is composed of 2-cyano-3-(pyridine-2-amino)-ethyl acrylate, E-2-[3,5-bis(trifluoromethyl) Phenyl] vinyl boronic acid pinacol ester, ene adenine and methyl vinyl [1] silaferrocene ring are produced by copolymerization.

[0031] The preparation method of the fluorine-containing boron ferrocene ring-based copolymer includes the following steps: 1 kg of 2-cyano-3-(pyridine-2-amino)-ethyl acrylate, E-2-[3,5-di (Trifluoromethyl)phenyl)vinylboronic acid pinacol ester 2kg, enadenine 1kg, methylvinyl[1...

Embodiment 3

[0035] A modified PVC cable material made of the following raw materials by weight: 70 parts of PVC resin, 20 parts of fluorine-containing boron ferrocene ring-based copolymer, 6 parts of ultra-high molecular weight polyethylene fiber, 8 parts of amino-terminated polyurethane, powder 7 parts of coal ash, 3.5 parts of oxidized paraffin, 8 parts of waste tire powder, and KH5701 parts of silane coupling agent.

[0036] Wherein, the fluorine-containing boron ferrocene ring-based copolymer is composed of 2-cyano-3-(pyridine-2-amino)-ethyl acrylate, E-2-[3,5-bis(trifluoromethyl) Phenyl] vinyl boronic acid pinacol ester, ene adenine and methyl vinyl [1] silaferrocene ring are produced by copolymerization.

[0037] The preparation method of the fluorine-containing boron ferrocene ring-based copolymer includes the following steps: 1 kg of 2-cyano-3-(pyridine-2-amino)-ethyl acrylate, E-2-[3,5-di (Trifluoromethyl)phenyl)vinyl borate pinacol ester 2kg, ene adenine 1kg, methyl vinyl [1] silaza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com