Preparation method of waterproof and flame-retardant adhesive for fiberboards

A flame retardant adhesive and fiberboard technology, applied in the field of fiberboard, can solve the problems of hindering the popularization and application of water-based polyurethane adhesives, poor water resistance, etc., and achieve the effects of increasing interface compatibility, good hydrophobicity, and improving water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

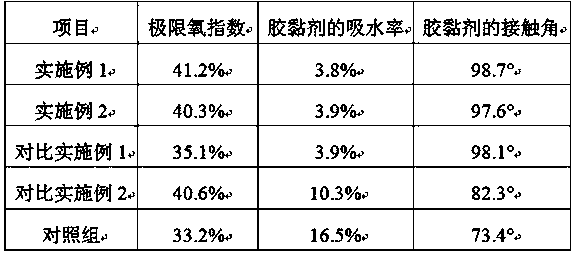

Examples

Embodiment 1

[0025] A preparation method of a waterproof flame-retardant adhesive for fiberboard, characterized in that it comprises the following steps, and the following raw materials are calculated in parts by weight:

[0026] (1) Hydrophobic modification method of acid-etched halloysite nanotubes:

[0027] After ultrasonically dispersing 1 part of acid-etched halloysite nanotubes in dry toluene for 30 minutes, connect it to the reflux device, blow in nitrogen gas, heat up to 120°C with mechanical stirring, add 0.02 parts of hexamethyldisilazane dropwise, and reflux reaction After 5 hours, centrifuge, wash 3 times with toluene, and dry in a drying oven at 120°C for 2 hours to obtain hydrophobically modified acid-etched halloysite nanotubes;

[0028] Among them, acid etching pretreatment of halloysite nanotubes: 1 part of halloysite nanotubes was pretreated in a muffle furnace at 400°C for 4h, then added to a sulfuric acid solution with a concentration of 2mol / L, and heated at 80°C Cond...

Embodiment 2

[0036] A preparation method of a waterproof flame-retardant adhesive for fiberboard, characterized in that it comprises the following steps, and the following raw materials are calculated in parts by weight:

[0037] (1) Hydrophobic modification method of acid-etched halloysite nanotubes:

[0038] After ultrasonically dispersing 2 parts of acid-etched halloysite nanotubes in dry toluene for 40 minutes, connect to the reflux device, blow in nitrogen gas, heat up to 125°C with mechanical stirring, drop 0.04 parts of hexamethyldisilazane, and reflux reaction After 4 hours, centrifuge, wash with toluene 5 times, and dry in a drying oven at 125°C for 1 hour to obtain hydrophobically modified acid-etched halloysite nanotubes;

[0039] Among them, acid etching pretreatment of halloysite nanotubes: 2 parts of halloysite nanotubes were pretreated in a muffle furnace at 410°C for 3h, then added to a sulfuric acid solution with a concentration of 2mol / L, and heated at 85°C Condensate an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com