Flexible color filter and method of manufacturing

A color filter, flexible technology, used in instruments, filters, nonlinear optics, etc., can solve problems such as limitations and low flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

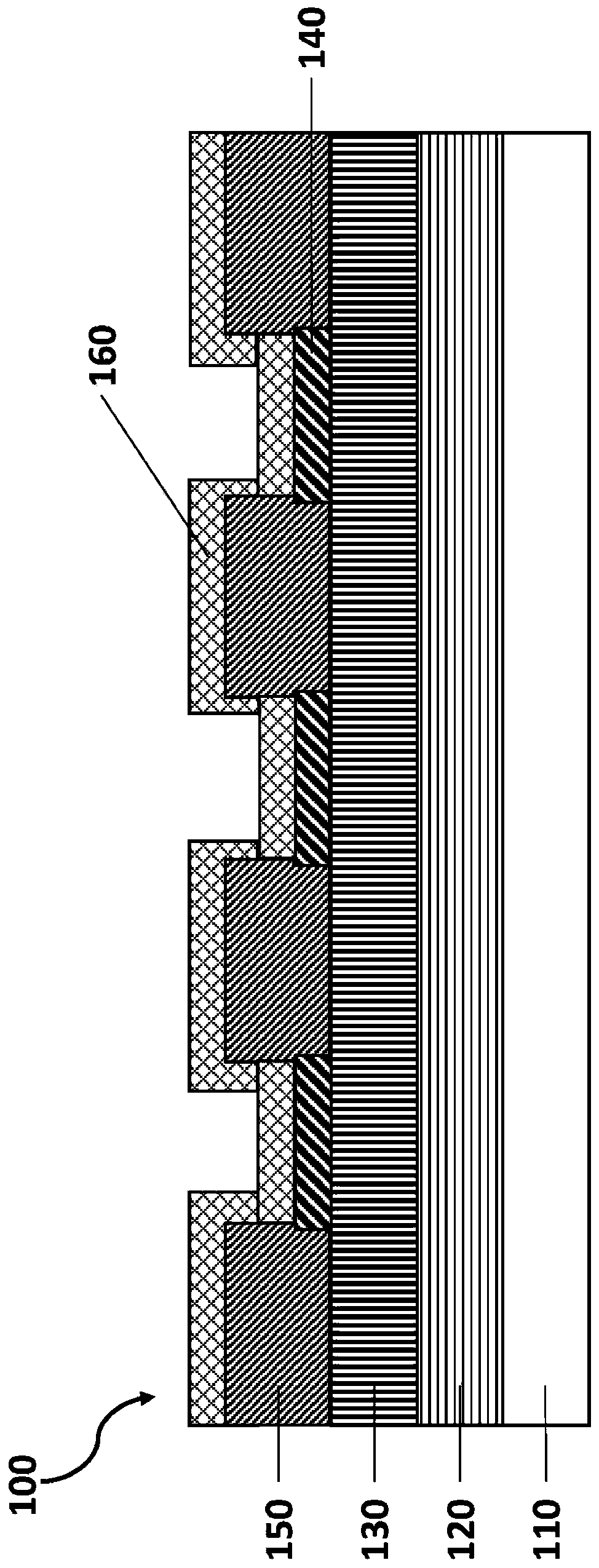

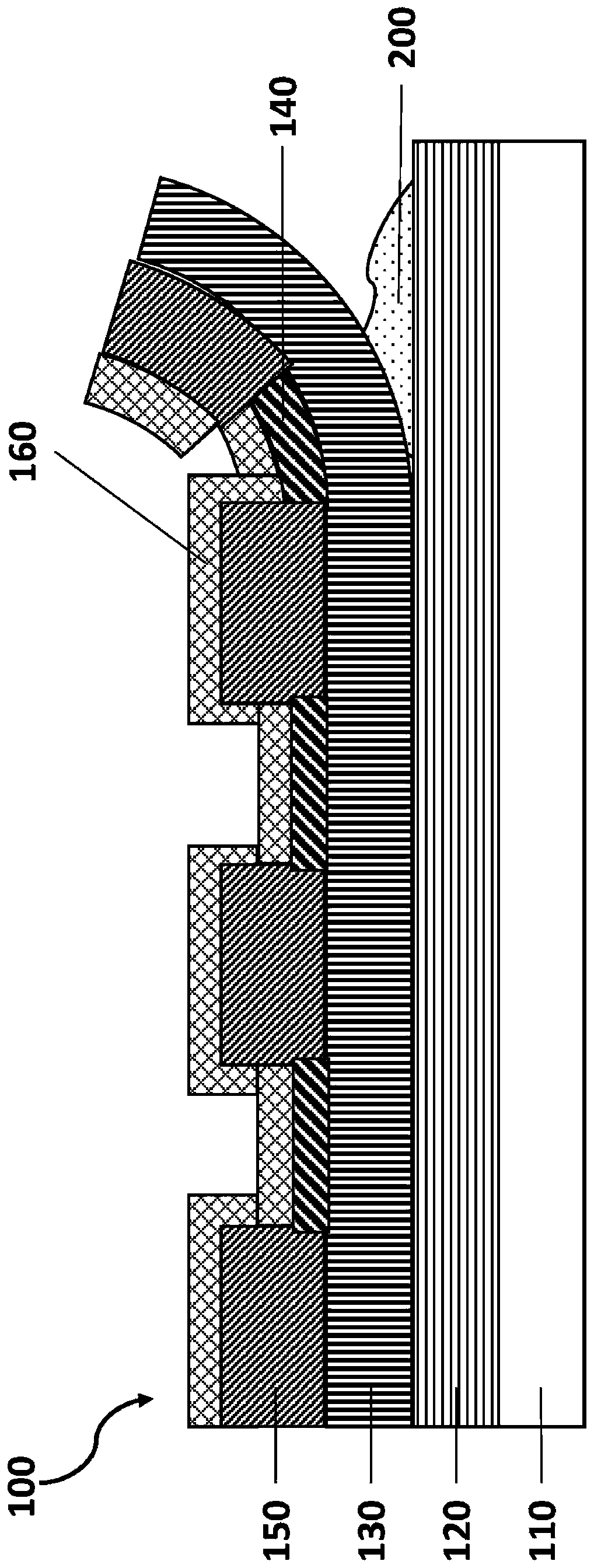

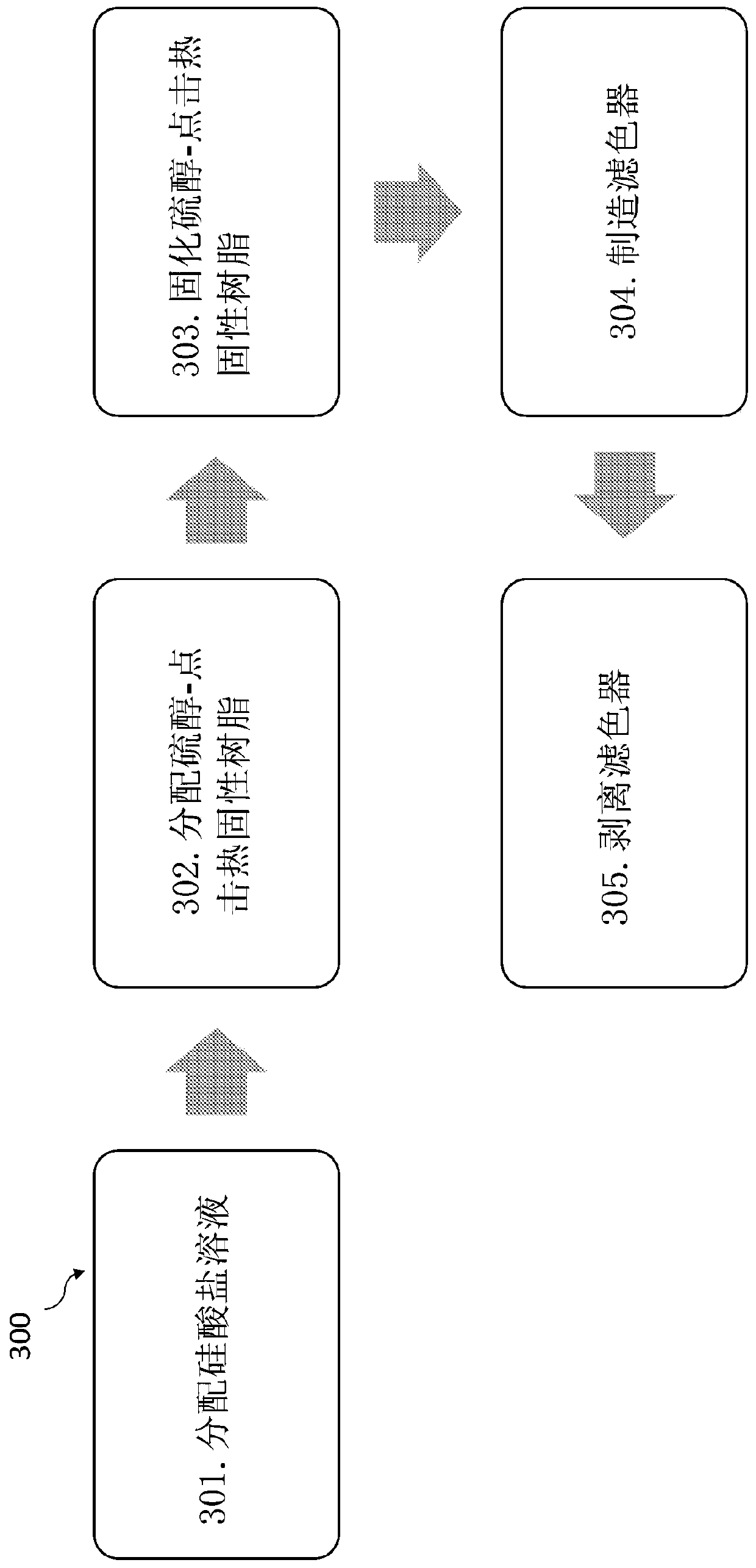

[0014] In the preparation of the polymer resin, the multifunctional thiol monomer and comonomer can be mixed, and the polymer resin can be injected into a reservoir (eg, a pressurized reservoir). Uniform sheet production can be performed on polymeric resins and by any adequate method including, but not limited to, slot die coating, rod coating, blade coating, spin coating, reaction injection molding or any combination thereof. The polymeric resin can be cured using electromagnetic radiation, such as heat, visible light, ultraviolet light, or any combination thereof. The polymer cured resin has a transparency of greater than 90% in the visible range and a haze of less than 1%. This is a desirable property for color filter substrates because light transmission directly affects the image quality and power consumption of LCD displays.

[0015] A black matrix pattern is used to prevent light leakage, so the backlight only passes through the desired sub-pixels. The black matrix p...

Embodiment 1

[0032] A 370mm x 470mm glass panel is used as a carrier. A thin release layer is deposited by dye coating and baked to remove solvent. A 50 μm layer of polymer resin was slot-die coated on top of the thin release layer and cured at 250° C. while irradiating with UV light for 1 hour. After curing the polymer resin, a 1.4 μm layer of photosensitive black ink was coated on the polymer resin by spin coating. The samples were then baked at 100 °C for 2 min to remove the solvent. Subsequently, a photomask was used to block UV light having a wavelength of 365 nm (i-line), followed by development to pattern the black matrix onto the polymer resin. The resulting samples were baked at 200°C for 2 minutes for a hard bake. After the hard-baking step, a layer of red resist was spin-coated on the sample with a thickness of 1.2 μm. The resulting samples were then baked at 100°C for 2 minutes for curing. A photomask is used to pattern the locations of the red subpixels on the black matri...

Embodiment 2

[0034] The procedure of Example 1, where an extra subpixel is used for yellow in RGBY configuration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| haze | aaaaa | aaaaa |

| transparency | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com