Fermented feed for cattle and sheep and preparation method of fermented feed

A technology for fermenting feed, cattle and sheep, applied in the field of animal husbandry, can solve the problems of unconventional energy and protein raw materials, insufficient utilization of plant organic calcium and phosphorus, lack of high-quality roughage, and high feed cost, so as to provide palatability and low cost. , the effect of high protein content of feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

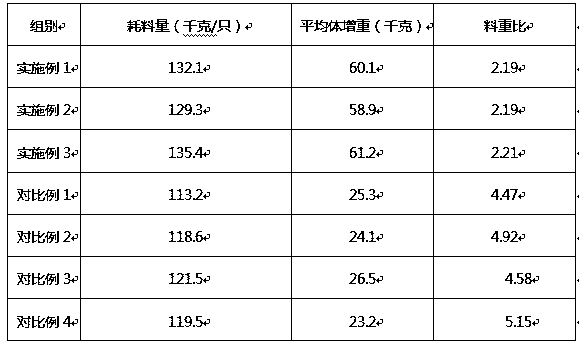

Examples

Embodiment 1

[0018] A fermented feed for cattle and sheep is made of the following percentages of raw materials: 28 wt% soybean meal, 22 wt% cotton meal, 12wt% corn gluten meal, 8 wt% oatmeal, and 20 wt% mixed bacterial solution.

[0019] A kind of preparation method of above-mentioned fermented feed, with soybean meal 28wt%, cottonseed meal 22wt%, corn gluten powder 12wt%, oat subflour 8wt%, mixed bacterium liquid 20wt% are mixed uniformly, be placed in the interior of belt breather valve In the film bag, ferment at 15°C for 7 days to obtain the fermented feed. The preparation method of described mixed bacterial solution adopts the following steps:

[0020] (1) Rejuvenate Saccharomyces cerevisiae, Bacillus subtilis, Lactobacillus plantarum, and Pediococcus pentosaceus respectively, and add 3wt% chili meal to the medium of each strain;

[0021] (2) Cultivate the Saccharomyces cerevisiae, Bacillus subtilis, Lactobacillus plantarum, and Pediococcus pentosaceae rejuvenated in step (1) at 30°...

Embodiment 2

[0024] A kind of preparation method of above-mentioned fermented feed, with soybean meal 32wt%, cottonseed meal 18wt%, corn gluten powder 17wt%, oats secondary powder 8wt%, mixed bacterial liquid 25wt%

[0025] Mix evenly, place in an inner membrane bag with a breathing valve, and ferment at 25°C for 5 days to obtain a fermented feed.

[0026] The preparation method of described mixed bacterial solution adopts the following steps:

[0027] (1) Rejuvenate Saccharomyces cerevisiae, Bacillus subtilis, Lactobacillus plantarum and Pediococcus pentosaceus respectively, and add 8wt% chili meal to the medium of each strain;

[0028] (2) Cultivate the rejuvenated Saccharomyces cerevisiae, Bacillus subtilis, Lactobacillus plantarum, and Pediococcus pentosaceus in step (1) for 36 hours at 35°C with a rotation speed of 25 rpm; wherein Saccharomyces cerevisiae, Bacillus subtilis, and plant milk The mass ratio of Bacillus and Pediococcus pentosaceus is 2:1:1:1.

[0029] Further, the cultu...

Embodiment 3

[0031] A kind of preparation method of above-mentioned fermented feed, 30wt% of soybean meal, 20wt% of cottonseed meal, 15wt% of corn gluten meal, 10wt% of oatmeal powder, 25wt% of mixed bacterial liquid are mixed uniformly, are placed in the inner membrane bag with breathing valve , fermented at 20°C for 6 days to obtain fermented feed.

[0032] The preparation method of described mixed bacterial solution adopts the following steps:

[0033] (1) Rejuvenate Saccharomyces cerevisiae, Bacillus subtilis, Lactobacillus plantarum and Pediococcus pentosaceus respectively, and add 5wt% chili meal to the culture medium of each strain;

[0034] (2) Cultivate the Saccharomyces cerevisiae, Bacillus subtilis, Lactobacillus plantarum, and Pediococcus pentosaceae rejuvenated in step (1) at 32°C with a rotation speed of 30 rpm for 30 hours; wherein Saccharomyces cerevisiae, Bacillus subtilis, and plant milk The mass ratio of Bacillus and Pediococcus pentosaceus is 2:1:1:1.

[0035] Further...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com