Supported sodium calcium phosphosilicate and medicines including the same

A sodium calcium phosphosilicate, loaded technology, applied in the field of materials, can solve the problems of rising to above the national standard 8.5, the pH value of the product rising to above 9, the consistency of the product becoming thinner, etc., and achieving the effect of long-term cleansing of the skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

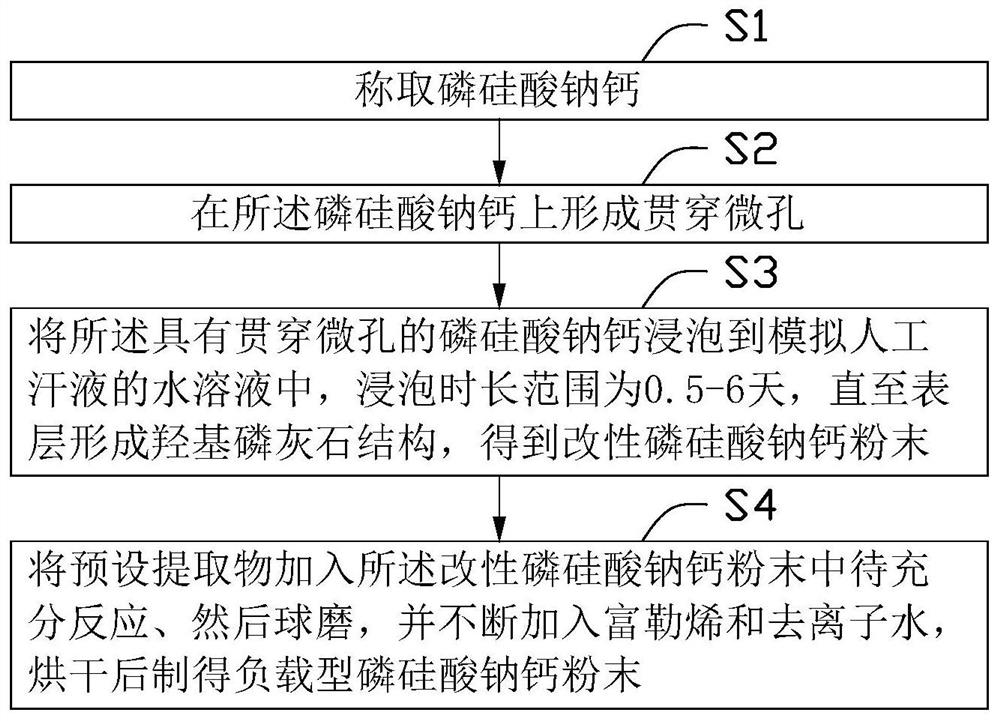

[0052] (1) Get sodium calcium phosphosilicate with a particle size of 1 nm to 150 μm, preferably 45S5 and 58S sodium calcium phosphosilicate. Sodium calcium phosphosilicate with particle size within 10 μm is preferred.

[0053] (2) Using a laser machine to irradiate the powder of sodium calcium phosphosilicate with laser light to produce nano-micropores with a pore diameter of 1 nm-100 μm that can penetrate through sodium calcium phosphosilicate.

[0054] (3) Soak the sodium calcium phosphosilicate with micropores in an aqueous solution simulating artificial sweat for 1-10 days, and filter the soaking solution to obtain modified sodium calcium phosphosilicate powder. In this step, a hydroxyapatite-like surface layer is formed.

[0055] Wherein, after the aforementioned steps, it includes: adding deionized water to the modified sodium calcium phosphosilicate powder to form a turbid solution, putting the turbid solution into an ultrasonic machine for cleaning 3 times, each time...

Embodiment 2

[0065] (1) Get 1000 g of sodium calcium phosphosilicate with a particle diameter of 150 μm, preferably 45S5 type and 58S type calcium sodium phosphosilicate.

[0066] (2) Microwaves are used to heat the sodium calcium phosphosilicate powder to produce nano-micropores with a pore diameter of 1 nm-100 μm that can penetrate the sodium calcium phosphosilicate.

[0067] (3) Soaking the microporous sodium calcium phosphosilicate into the aqueous solution of simulated artificial sweat for 3-8 days, and filtering the soaking solution to obtain modified sodium calcium phosphosilicate powder.

[0068] Wherein, after the aforementioned steps, it includes: adding deionized water to the modified sodium calcium phosphosilicate powder to form a turbid solution, putting the turbid solution into an ultrasonic machine for cleaning 3 times, each time for 1-20 minutes, and filtering again to obtain the after-cleaning solution. Modified calcium sodium phosphosilicate powder.

[0069] (4) Take 100...

Embodiment 3

[0071] (1) Take 10 μm sodium calcium phosphosilicate, preferably 45S5 type and 58S type sodium calcium phosphosilicate.

[0072] (2) A laser machine is used to irradiate the powder of sodium calcium phosphosilicate with laser light to produce nano-micropores with a pore diameter of 2 μm that can penetrate the sodium calcium phosphosilicate.

[0073] (3) Soak the sodium calcium phosphosilicate with micropores in an aqueous solution simulating artificial sweat for 3-4 days, and filter the soaking solution to obtain modified sodium calcium phosphosilicate powder.

[0074] Wherein, after the aforementioned steps, it includes: adding deionized water to the modified sodium calcium phosphosilicate powder to form a turbid solution, putting the turbid solution into an ultrasonic machine for cleaning 3 times, each time for 1-20 minutes, and filtering again to obtain the after-cleaning solution. Modified calcium sodium phosphosilicate powder.

[0075] (4) Take 100g of modified sodium ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com