Graphene anti-fouling device

An anti-scaling and graphene technology, which is applied in complex/solubilizing agent treatment, energy wastewater treatment, etc., can solve the problems of high power consumption, complicated equipment, inconvenient maintenance, etc., and achieve high efficiency of scale removal, low cost, Simple and reasonable structure

Active Publication Date: 2022-05-31

CHANGZHOU UNIV

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] However, due to their respective defects, the traditional descaling methods cannot completely remove the fouling of the textile

For example, the magnetic treatment anti-scaling device is suitable for anti-scaling of hot water boilers and their heating systems, but the corrosion products in the system affect the use effect of the magnetic treatment device. When used for large-capacity hot water boilers and heating network descaling, it needs The iron removal device makes the system complex and inconvenient for application

Ultrasonic technology can play a certain role in anti-scaling and descaling, but it consumes a lot of electric energy just like the electric field, the input cost is high, and the equipment is complicated and maintenance is inconvenient, which is not conducive to large-scale promotion

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

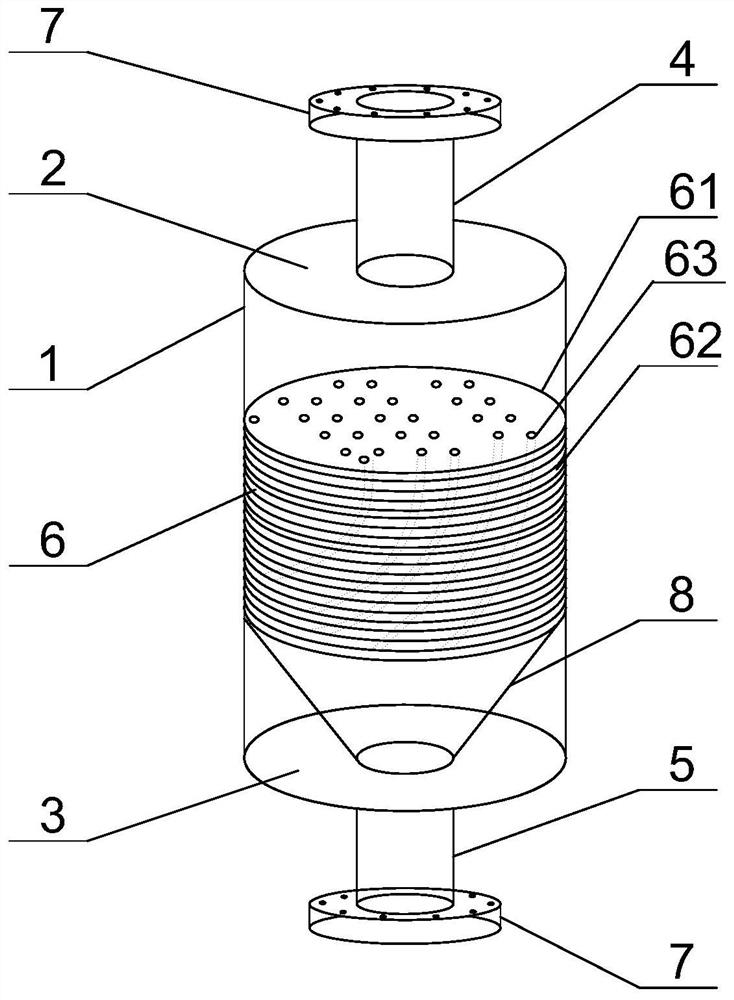

[0017] Now in conjunction with the accompanying drawings, the present invention will be described in further detail. These drawings are simplified schematic diagrams, only

[0019] The upper end of the upper connecting pipe 4 and the lower end of the lower connecting pipe 5 are all equipped with a flange 7. Between the anti-fouling packing 6 and the bottom of the cylinder 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

The present invention relates to the technical field of water treatment equipment, in particular to a graphene anti-fouling device, comprising a cylinder, the upper end and the lower end of the cylinder are respectively sealed with an upper cover and a lower cover, and an upper connecting pipe is connected to the upper cover , the lower cover is connected with a lower connecting pipe, and the anti-scaling filler is fixedly installed in the cylinder. The anti-scaling filler is provided with flow channel holes connecting up and down. The present invention utilizes the strong conductivity of graphene and the strong potential difference formed by carbon and zinc to inhibit the formation and growth of calcium carbonate crystal nuclei, and the eddy current formed by the flow channel hole continues to form a eddy current after passing through the diversion cone, which has a positive effect on the subsequent tube wall The scouring effect makes most of the metastable crystals suspended in the water and is easy to be washed away by the water, so as to achieve the purpose of scale inhibition. The structure is simple and reasonable, the cost is low, and the scale removal efficiency is high.

Description

Graphene anti-fouling device technical field The present invention relates to the technical field of water treatment equipment, in particular to a kind of graphene anti-scaling device. Background technique Dirt refers to a layer of solid material that gradually accumulates on the solid surface in contact with the unclean fluid. Often what we call liquid-side fouling, it usually exists in the form of a mixture. [0003] Dirt is a common phenomenon that exists widely in the production process of life. Especially in the process of heat exchange, it is more serious out. The survey shows that more than 90% of the heat exchange equipment has different degrees of fouling. Fouling heat will be formed after the heat exchange surface is fouled Small changes in pipe diameter will also lead to a decrease in flow rate or an increase in pressure drop, even Causes local heat exchange and leads to accidents; and the increase of thermal resistance reduces the thermal efficiency in...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C02F5/08

CPCC02F5/08Y02W10/37

Inventor 雷雨戴竹青马建锋王晋

Owner CHANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com