Ultrasonic-assisted glass heat-bending device based millimeter-wave heat source and control method

An ultrasonic-assisted, millimeter-wave technology, applied in glass manufacturing equipment, glass forming, glass reshaping, etc., can solve the problems that are difficult to meet the manufacturing requirements of 3D ultra-thin ultra-thin glass surface quality, crystallization, holes, cracks, impact Problems such as the quality of hot bending, to achieve the effect of promoting glassy flow, improving material flow, and facilitating processing parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

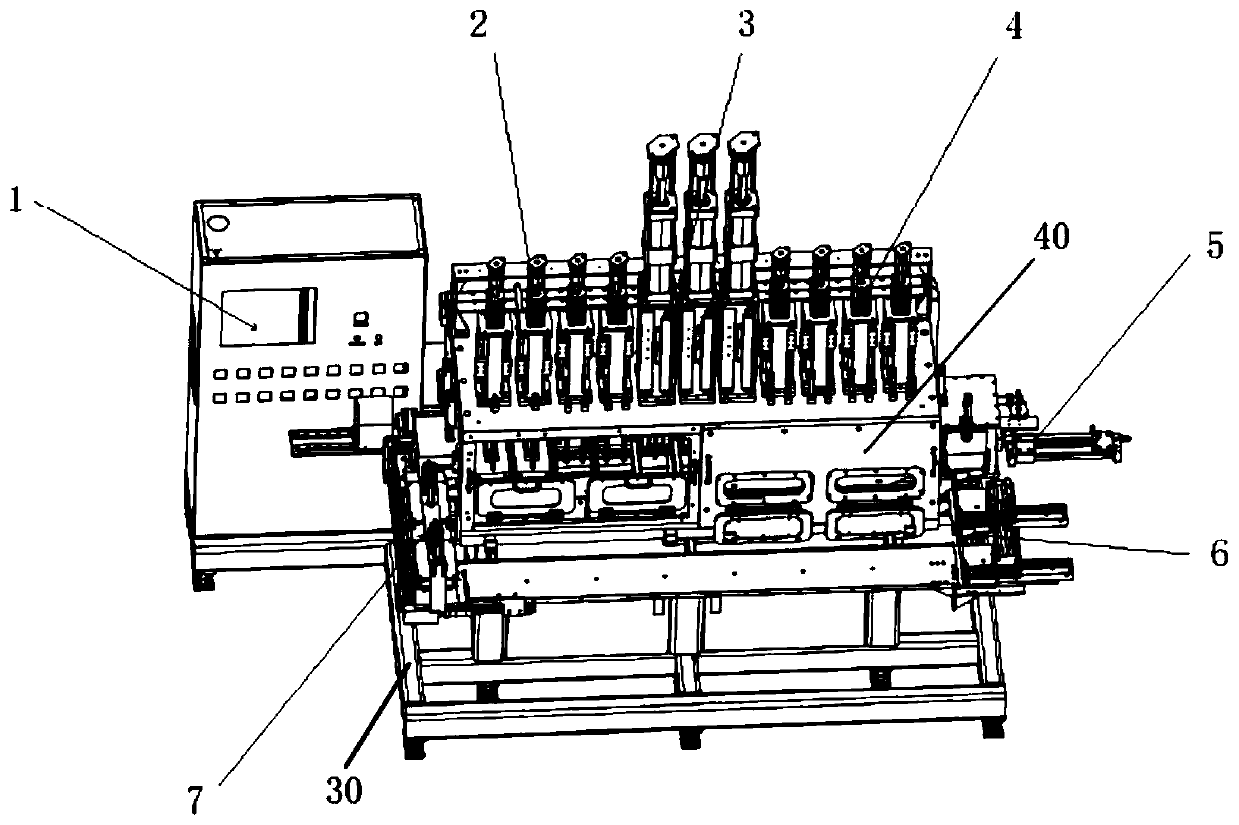

[0053] Processing environment: domestic hot-bending machine tool, using millimeter-wave heat source, graphite mold, ultrasonic transducer installed at the bottom, the glass sheet to be processed is ultra-thin glass, and the ultra-thin glass is bent into 2.5D ultra-thin glass. The preheating zone, hot bending pressurization zone, holding pressure zone and cooling zone are each equipped with 3 stations, which are arranged sequentially. The preheating zone is the first station, the second station and the third station, and the hot bending pressurization zone is the first station. The four stations, the fifth station and the sixth station, the holding zone is the seventh station, the eighth station and the ninth station, and the cooling zone is the tenth station, the eleventh station and the twelfth station.

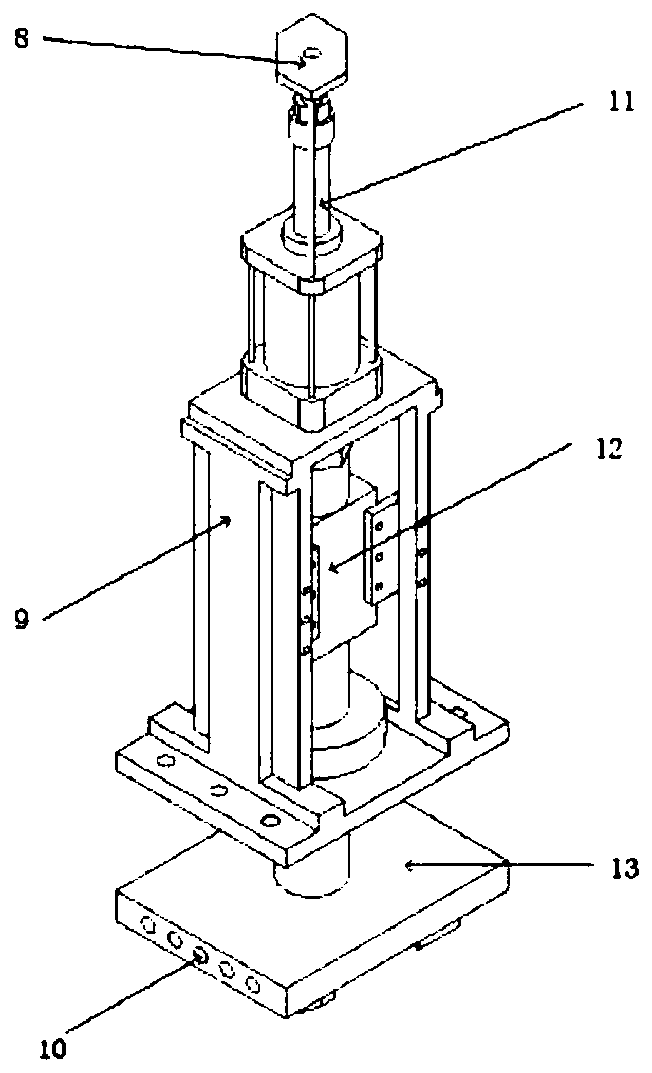

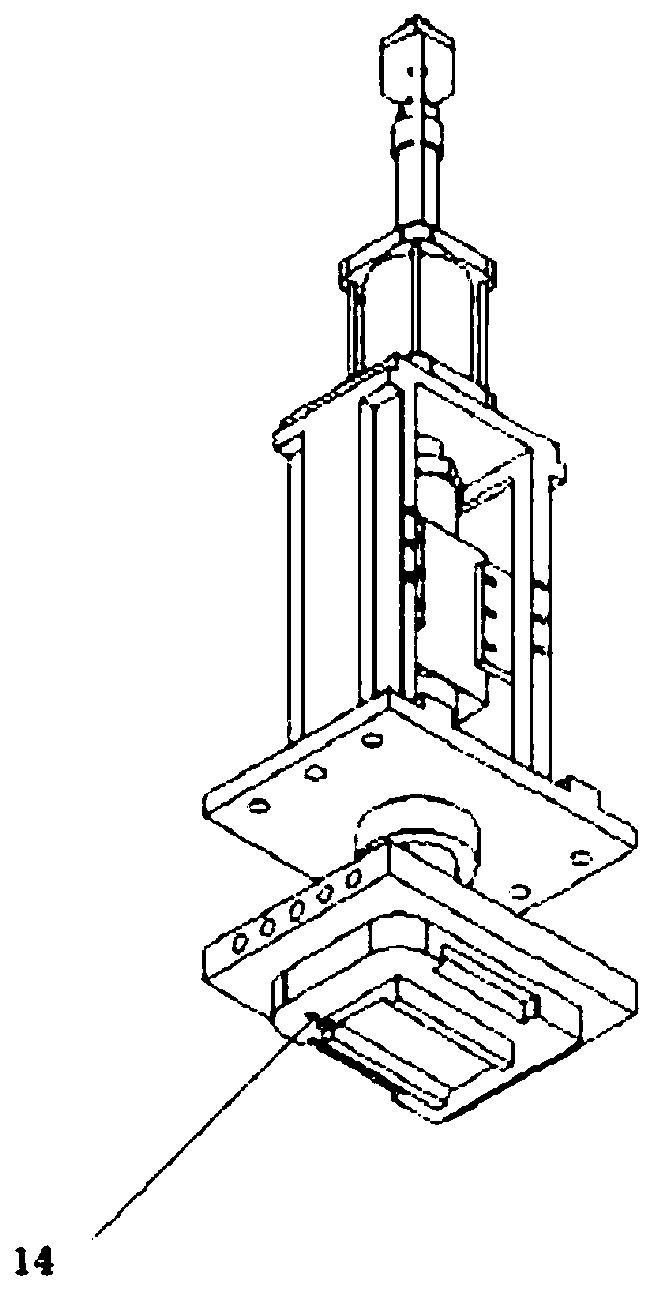

[0054] The machine tool provides a servo system for controlling the movement of the mold. The machine tool is an existing known device. The hot bending device includes a mill...

Embodiment 2

[0057] Processing environment: domestic hot bending machine, using millimeter wave heat source, the mold is made of graphite, with an ultrasonic transducer installed at the bottom, the glass sheet to be processed is ultra-thin glass, and the ultra-thin glass is bent into 3D ultra-thin glass. The preheating zone, hot bending pressurization zone, holding pressure zone and cooling zone are each equipped with 3 stations, which are arranged sequentially. The preheating zone is the first station, the second station and the third station, and the hot bending pressurization zone is the first station. The four stations, the fifth station and the sixth station, the holding zone is the seventh station, the eighth station and the ninth station, and the cooling zone is the tenth station, the eleventh station and the twelfth station.

[0058]The machine tool provides a servo system that controls the movement of the mold, and the auxiliary devices include millimeter wave heat sources, ultraso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com