Low-carbon ultra-low-carbon carbon-containing refractory material containing in-situ peeled two-dimensional micro-nano graphite flake phenolic resin composition, and preparation method thereof

A refractory material and phenolic resin technology, applied in the field of refractory materials, can solve the problems of large-scale commercialization of unsuitable low-carbon and ultra-low carbon refractory materials, easy agglomeration of nano-carbon materials, and difficulty in uniform dispersion, etc. The effect of thermal shock resistance and slag erosion resistance retention, excellent spalling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

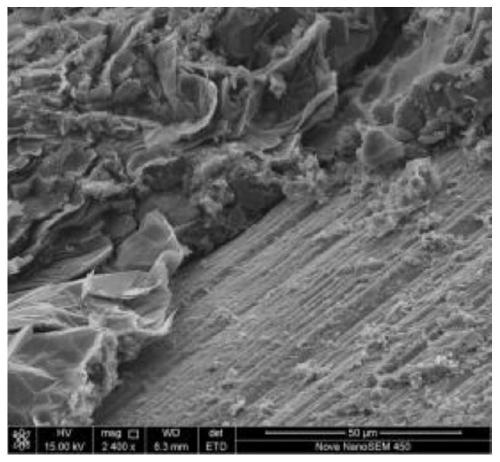

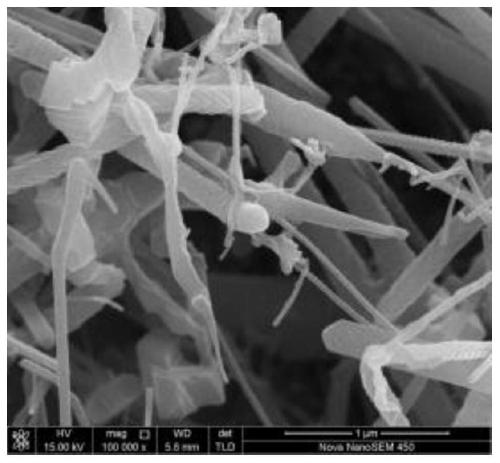

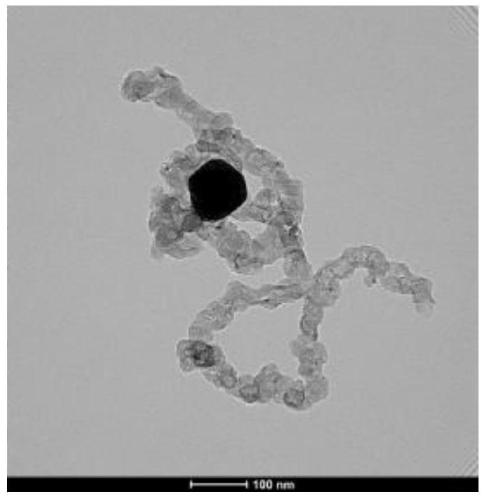

[0027] A low-carbon magnesia-carbon refractory material containing in-situ exfoliated two-dimensional micro-nano graphite flakes combined with phenolic resin. The components are calculated by weight percentage: 60 wt% of fused magnesia particles, of which the particle size is 5-3mm. 15wt%, particle size 3 ~ 1mm accounted for 25wt% of the total ingredients, particle size ≤ 1mm accounted for 20wt% of the total ingredients; fused magnesia fine powder accounted for 28wt% of the total ingredients, particle size ≤ 0.074mm; phenolic resin binder 6wt% , 4 wt% of flake graphite, 0.1 wt% of nickel nitrate hexahydrate, 0.4 wt% of Al powder with a particle size of ≤0.074mm, 0.5 wt% of Si powder with a particle size of ≤0.074mm, and 1 wt% of high-temperature asphalt powder.

[0028] A method for preparing a low-carbon magnesium-carbon refractory material combined with a two-dimensional nano-graphite sheet phenolic resin exfoliated in situ, comprising the following steps:

[0029] (1) earli...

Embodiment 2

[0039] An ultra-low-carbon aluminum-carbon refractory material containing in-situ exfoliated two-dimensional micro-nano graphite flakes combined with phenolic resin, the components are calculated by weight percentage: 65wt% of sintered corundum particles, of which 18wt% of the total ingredients are sintered corundum particles with a particle size of 5-3mm %, particle size 3 ~ 1mm accounts for 25wt% of the total ingredients, particle size ≤ 1mm accounts for 22wt% of the total ingredients; sintered corundum fine powder accounts for 26wt% of the total ingredients, particle size ≤ 0.074mm; phenolic resin binder 5wt%, flake graphite 2wt%, 0.3wt% cobalt nitrate hexahydrate, 0.4wt% Al powder with a particle size ≤ 0.074mm, 0.4wt% Si powder with a particle size ≤ 0.074mm, and 0.9wt% high-temperature asphalt powder.

[0040] A method for preparing a low-carbon magnesium-carbon refractory material combined with in-situ exfoliated two-dimensional micro-nano graphite sheet phenolic resin, ...

Embodiment 3

[0051] A low-carbon magnesia-aluminum-carbon refractory material containing in-situ exfoliated two-dimensional micro-nano graphite flakes combined with phenolic resin. The components are calculated by weight percentage: fused magnesia particles 40wt%, of which the particle size is 5-3mm. 12wt% of the total ingredients, 16wt% of the total ingredients with a particle size of 3-1mm, 12wt% of the total ingredients with a particle size of ≤1mm; 25wt% of fused corundum particles, 7wt% of the total ingredients with a particle size of 5-3mm, 1mm accounted for 10wt% of the total ingredients, particle size ≤ 1mm accounted for 8wt% of the total ingredients; fused magnesia fine powder accounted for 13wt% of the total ingredients, particle size ≤ 0.074mm; fused corundum fine powder accounted for 11wt% of the total ingredients, Particle size ≤ 0.074mm; phenolic resin binder 6wt%, flake graphite 3wt%, iron nitrate nonahydrate 0.3wt%, particle size ≤ 0.074mm Al-Mg alloy powder 0.4wt%, particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Normal temperature compressive strength | aaaaa | aaaaa |

| High temperature flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com