Preparation method of antibacterial chitosan quaternary ammonium salt and product

A technology of quaternary ammonium salt and antibacterial shell, which is applied in the field of preparation of antibacterial chitosan quaternary ammonium salt, can solve the problems of cytotoxic hemolysis and poor biocompatibility, and achieve good biocompatibility, low biocompatibility, The effect of improving the antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

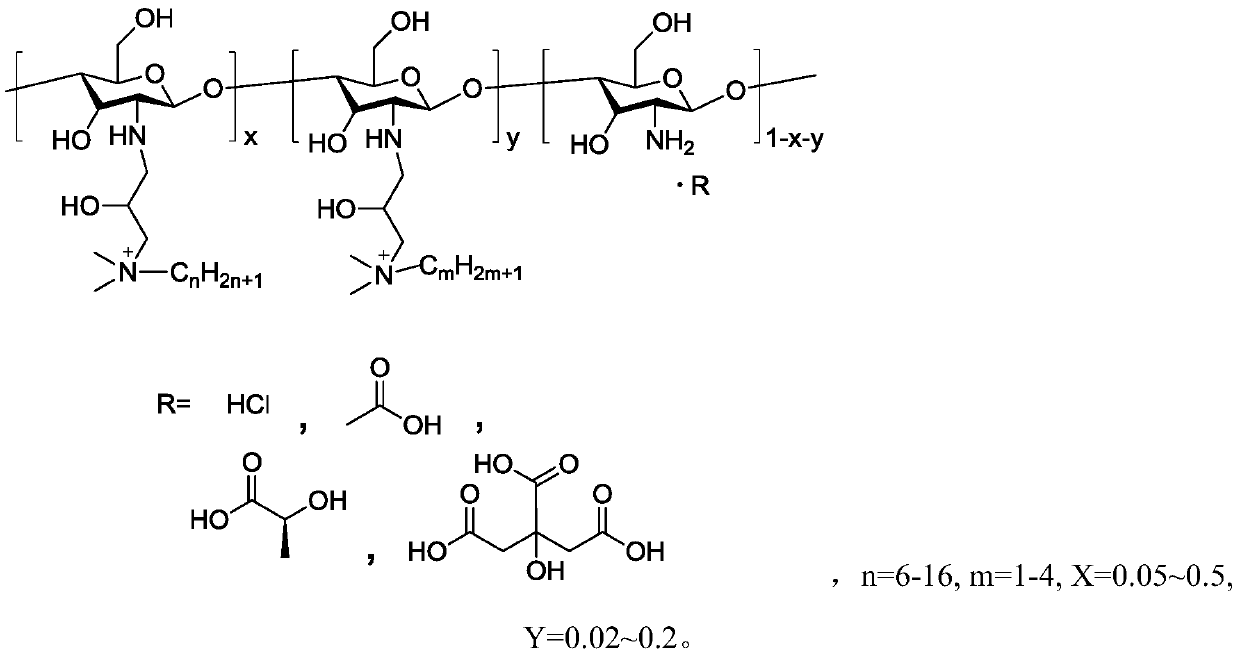

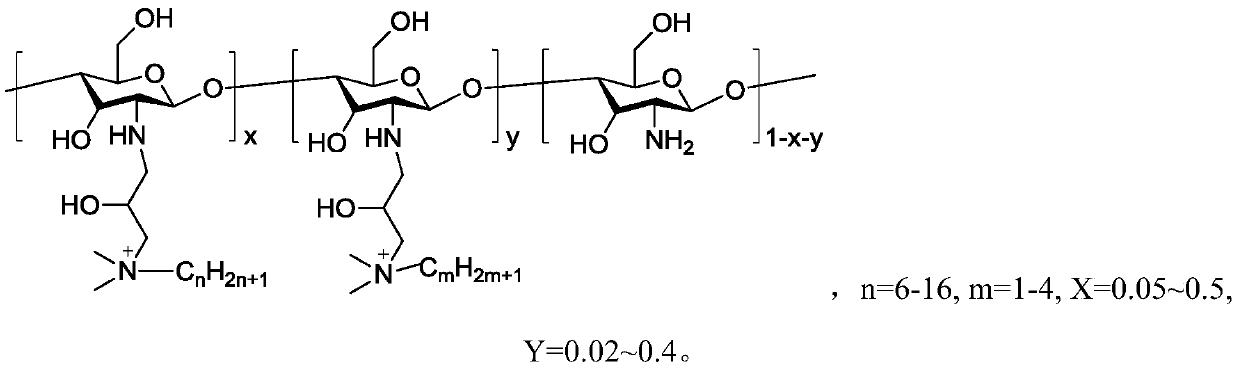

[0025] Synthetic antibacterial chitosan quaternary ammonium salt X1, comprises the following steps::

[0026] 1) Add 3g of epichlorohydrin dropwise to 4g of N,N-dimethylhexylamine, stir at 55°C for 2h, after the end, precipitate and wash with petroleum ether twice, and dry under reduced pressure to obtain long-chain alkyl chain epoxy Quaternary ammonium salt A1 (2-Oxiranemethanaminium, N-hexane-N, N-dimethyl-), the molecular formula is

[0027] 2) Add 1.0g of epichlorohydrin dropwise to 1.0g of N,N-dimethylethylamine, stir at 50°C for 36 hours, after the end, precipitate and wash with ether twice, dry under reduced pressure to obtain short-chain alkyl Epoxy quaternary ammonium salt B1, the molecular formula is

[0028] 3) Add 10g of chitosan hydrochloride (deacetylation degree 85%, molecular weight 80,000) into 2L of water, heat and dissolve at 60°C, add hydrochloric acid to adjust pH=4, and then mix 15g of epoxy quaternary ammonium salt A1 and 7.5 g epoxy quaternary amm...

Embodiment 2

[0031] Synthesis of antibacterial chitosan quaternary ammonium salt X2, comprising the following steps:

[0032] 1) Add 2g of epichlorohydrin dropwise to 4g of N,N-dimethyloctylamine, stir at 40°C for 24h, after the end, precipitate and wash with ether twice, dry under reduced pressure to obtain long alkyl chain epoxy quaternary ammonium salt A2 (2-Oxiranemethanaminium, N-octyl-N, N-dimethyl-), the molecular formula is

[0033] 2) Add 2.0g of epichlorohydrin dropwise to 5.0g of N,N-dimethylpropylamine, stir at 40°C for 6 hours, after the end, precipitate and wash with ether twice, dry under reduced pressure to obtain epoxy quaternary ammonium salt B2, Molecular formula is

[0034] 3) Add 5 g of chitosan citrate (deacetylation degree 85%, molecular weight 80,000) into 500 mL water, heat and dissolve at 70° C., adjust pH=5 with citric acid. Afterwards, 7.5 g of epoxy quaternary ammonium salt A2 and 3 g of epoxy quaternary ammonium salt B2 were dissolved in 20 mL of deioniz...

Embodiment 3

[0037] Synthetic antibacterial chitosan quaternary ammonium salt X3, comprises the following steps:

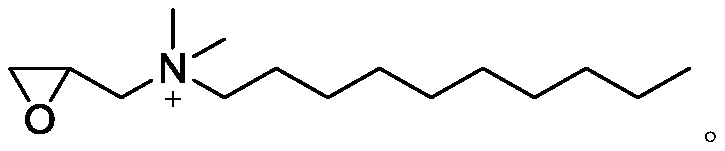

[0038] 1) Add 3g of epichlorohydrin dropwise to 5g of N,N-dimethyldecylamine, heat and stir at 50°C for 3h, after the reaction is completed, wash the reaction solution with n-hexane precipitation three times, and then vacuum dry to obtain quaternization Reagent A3 (2-Oxiranemethanaminium, N-decyl-N, N-dimethyl-), the molecular formula is:

[0039]

[0040] 2) Add 1.0g of epichlorohydrin dropwise to 4.0g of N,N-dimethylbutylamine, stir at 40°C for 4 hours, after the end, precipitate and wash with ether twice, dry under reduced pressure to obtain epoxy quaternary ammonium salt B3, the molecular formula is

[0041] 3) Add 5 g of chitosan hydrochloride (deacetylation degree 90%, molecular weight 30,000) into 500 mL deionized water, heat to dissolve at 50° C., and adjust pH=3. After that, 4g of epoxy quaternary ammonium salt A3 and 2g of epoxy quaternary ammonium salt B3 wer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com