High-strength lignin/polyvinyl alcohol composite antibacterial aquagel and preparation method

A kind of polyvinyl alcohol, compound antibacterial technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

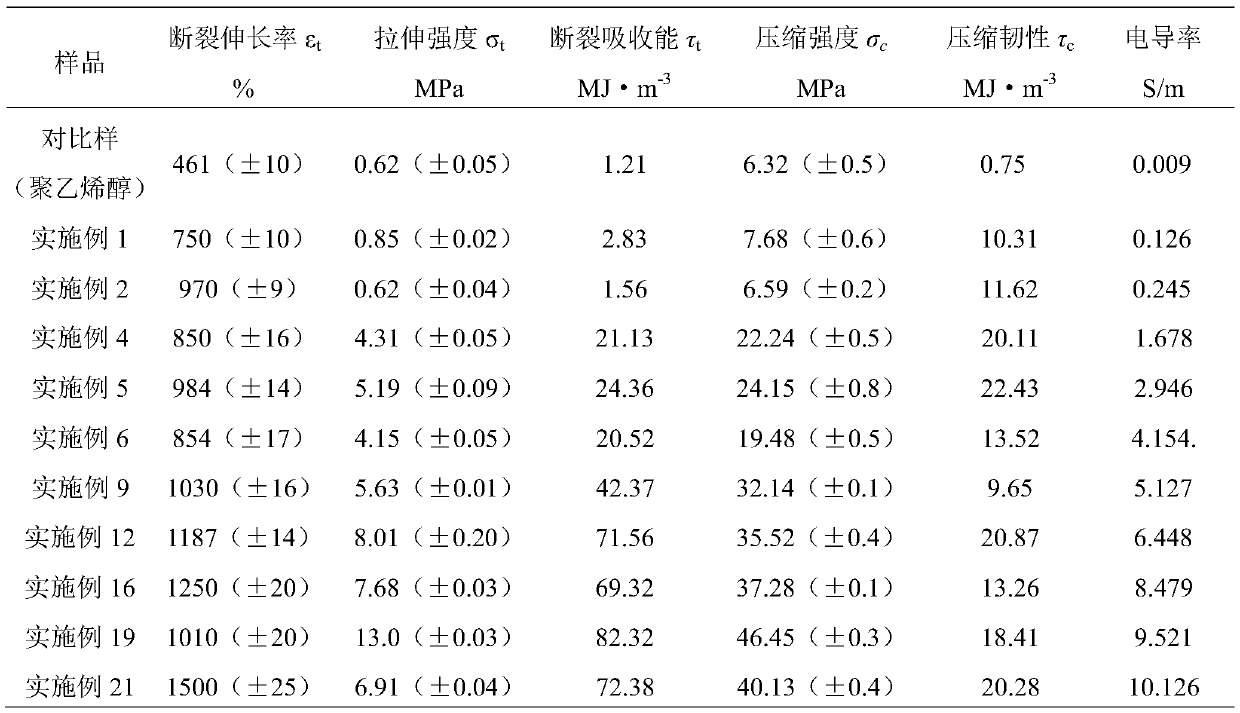

Image

Examples

Embodiment 1

[0033] Take 4.5 parts by mass of polyvinyl alcohol, 0.5 parts by mass of lignin, add 72.4 parts by volume of water; 18.1 parts by volume of DMSO solution, heat at 70°C, stir mechanically at 100rpm for 1h, pour the fully dissolved mixed solution into the mold, and heat at room temperature Freeze for 12 hours after natural cooling, thaw for 2 hours, soak the thawed composite hydrogel in deionized water for 24 hours for solvent exchange, and then soak the solvent-exchanged composite hydrogel in 0.01mol / L silver nitrate solution 1h, then soak it in 0.1mol / L sodium citrate for 1h, and finally obtain the finished product of lignin / polyvinyl alcohol / silver composite hydrogel. Wherein, the selected lignin is lignosulfonic acid, a by-product of sulfite pulping.

Embodiment 2

[0035] Take 5 parts by mass of polyvinyl alcohol, 0.5 parts by mass of lignin, add 66.15 parts by volume of water; 28.35 parts by volume of DMSO solution, heat at 80°C, stir mechanically at 120rpm for 2h, pour the fully dissolved mixed solution into the mold, and heat at room temperature Freeze for 12 hours after natural cooling, thaw for 2 hours, soak the thawed composite hydrogel in deionized water for 24 hours for solvent exchange, and then soak the solvent-exchanged composite hydrogel in 0.02mol / L silver nitrate solution 2h, then soak it in 0.2mol / L dopamine for 2h, and finally obtain the finished product of lignin / polyvinyl alcohol / silver composite hydrogel. Wherein, the selected lignin is lignosulfonic acid, a by-product of sulfite pulping.

Embodiment 3

[0037]Take 5.5 parts by mass of polyvinyl alcohol, 1.5 parts by mass of lignin, add 55.8 parts by volume of water; 37.2 parts by volume of DMSO solution, heat at 90°C, stir mechanically at 300rpm for 3h, pour the fully dissolved mixed solution into the mold, and heat at room temperature Freeze for 12 hours after natural cooling, thaw for 2 hours, soak the thawed composite hydrogel in deionized water for 24 hours for solvent exchange, and then soak the solvent-exchanged composite hydrogel in 0.03mol / L silver nitrate solution 3h, then soak it in 0.3mol / L sodium citrate for 3h, and finally obtain the finished product of lignin / polyvinyl alcohol / silver composite hydrogel. Wherein, the selected lignin is lignosulfonic acid, a by-product of sulfite pulping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com