Method for improving beer bitterness and storage stability by adding CO2 hop extract

A technology of storage stability and hop extract, which is applied in the field of beer brewing, can solve the problems such as the reduction of beer stability when exposed to light, and achieve the effects of ensuring flavor and quality, ensuring stability, and increasing bitterness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] One by adding CO 2 The method of improving the bitterness and storage stability of beer with hop extract. After the wort is cooled and swirled in the beer brewing process, hop extract is added before the fermentation stage. The amount of hop extract is 0.5g / L; the hop extract is CO 2 Hop extract, CO 2 Hop extract is made from hop pellets by CO 2 Made after extraction, CO 2 The content of iso-alpha-acid in hop extract is 35%-40%.

[0030] The CO 2 Hops extract is prepared by the following method:

[0031] (1) Take the hop raw material crushed to a particle size of 0.5-1 mm, put it into the extraction column of the supercritical CO2 fluid extraction system and seal it, raise the temperature of the extraction system to 45 ° C, increase the pressure to 25 MPa, start extraction, and keep the constant temperature and pressure for 2 hours , to obtain the extracted CO 2 mixed fluid;

[0032] (2) The extracted CO 2 The mixed fluid is input into the separator, and the tem...

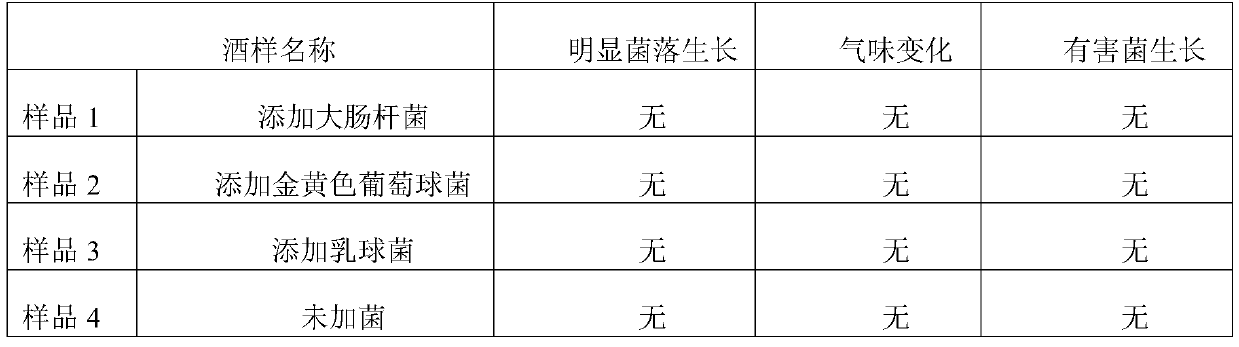

experiment example

[0039] Experimental example: beer performance test

[0040] 1. Bitterness value test of finished beer:

[0041] Reagent:

[0042] 2,2,4-Trimethylpentane (isooctane), spectrophotometrically pure or equivalent.

[0043] Hydrochloric acid, 3mol / L.

[0044] Octanol, reagent pure or double distilled liquid with equivalent concentration.

[0045] equipment:

[0046] Shaker, benchtop or eccentric, adjusts the vertical side of the extension arm to maintain the horizontal position of the test tube.

[0047] Compact spectrophotometer, UV range.

[0048] Centrifuge, 50mL, screw cap with glass stopper or tetrafluoroethylene liner.

[0049] The centrifuge is suitable for 50mL centrifuge tubes.

[0050] method:

[0051] Dip the test tube with a small amount of octanol with the tip, draw 10.0 mL of the cold beer (not degassed, 10° C.) of Example 1 and Comparative Example 1 into a 50 mL centrifuge tube, add 1 mL of 3 mol / L hydrochloric acid and 20 mL of isooctane. Close the stopper and...

Embodiment 2

[0081] One by adding CO 2 The method of improving the bitterness and storage stability of beer with hop extract. After the wort is cooled and swirled in the beer brewing process, hop extract is added before the fermentation stage. The amount of hop extract is 0.3g / L; the hop extract is CO 2 Hop extract, CO 2 Hop extract is made from hop pellets by CO 2 Made after extraction, CO 2 The content of iso-alpha-acid in hop extract is 35%-40%.

[0082] The CO 2 Hops extract is prepared by the following method:

[0083] (1) Take the hop raw material crushed to a particle size of 0.5-1 mm and put it into supercritical CO 2 After the extraction column of the fluid extraction system is sealed, the temperature of the extraction system is raised to 40°C, the pressure is increased to 20MPa, and the extraction is started, and the extraction is kept at constant temperature and pressure for 3 hours to obtain the extracted CO 2 mixed fluid;

[0084] (2) The extracted CO 2 The mixed fluid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com