Cathode drum for electrolytic deposition

A technology of electrolytic deposition and cathode roll, applied in the direction of electrode, electrolysis process, electroforming, etc., can solve the problems of difficult welding, high cost, influence on the quality of metal foil, etc., and achieve the effect of maintaining firmness and expanding contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

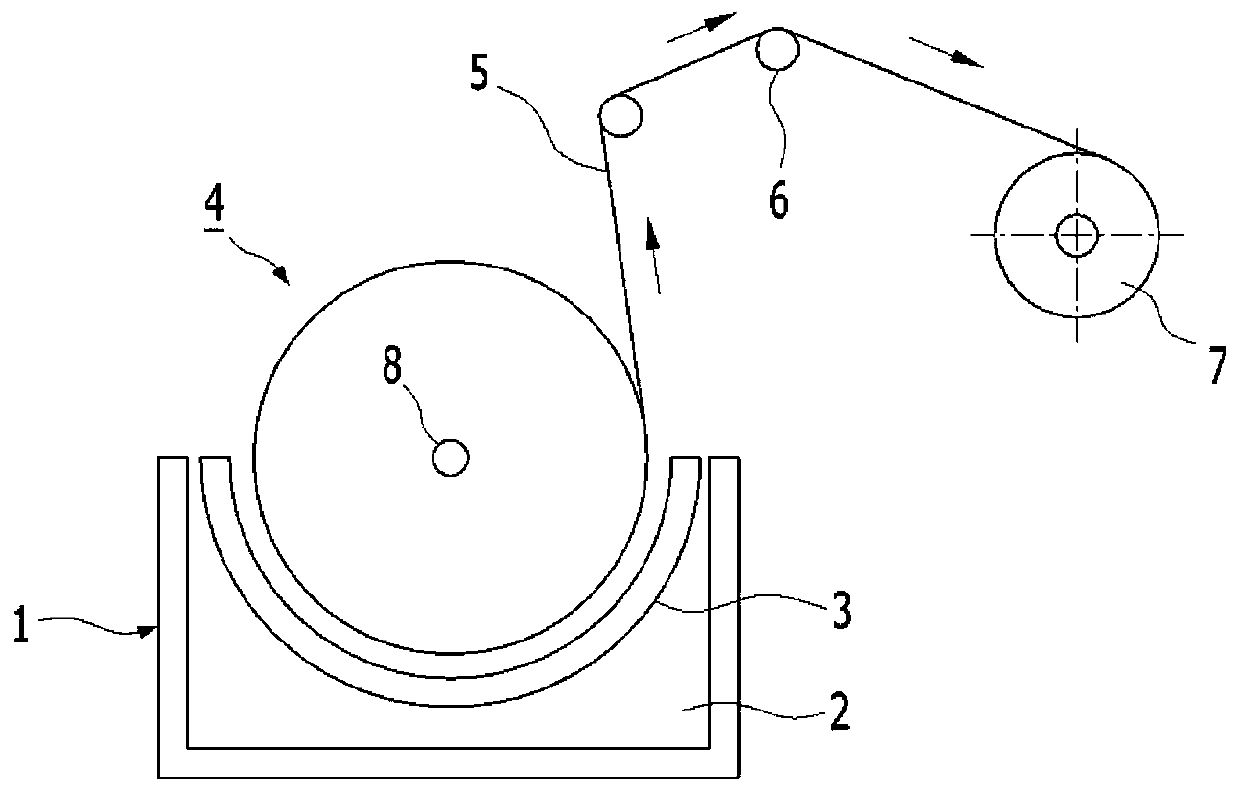

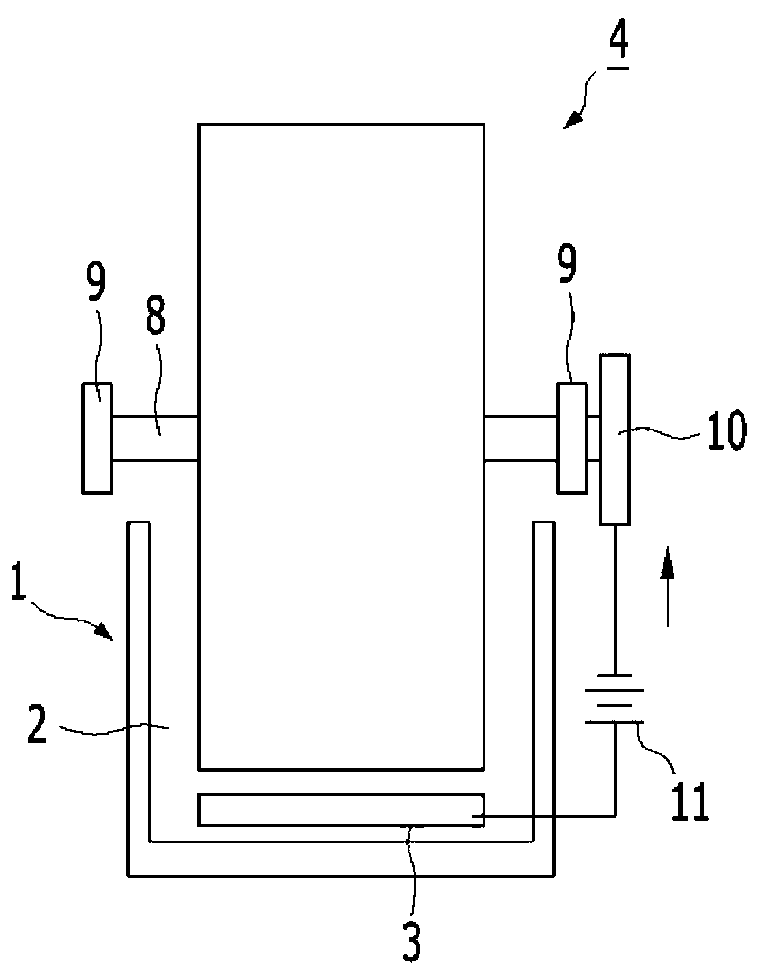

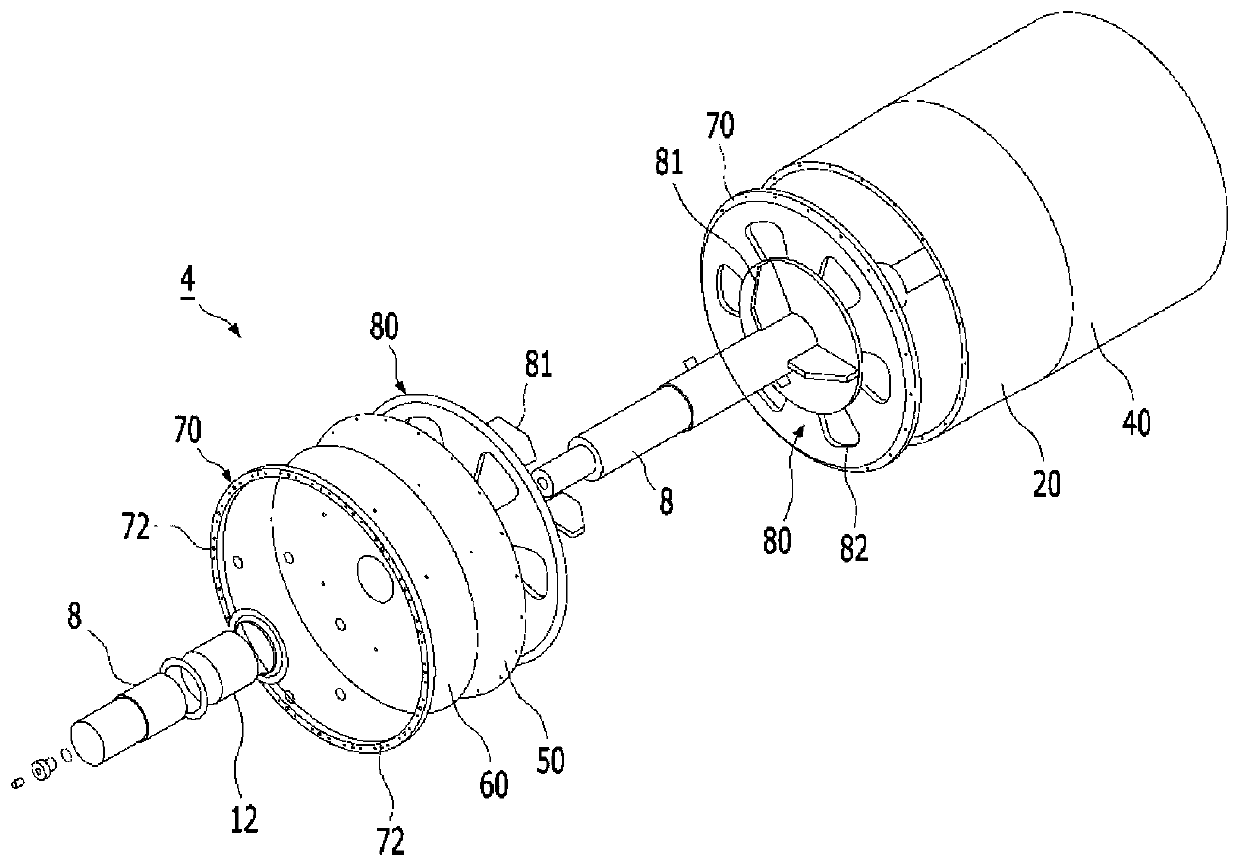

[0036] Such as image 3 and Figure 4 As shown, the structure of the cathode roller 4 of the present invention includes: a rotating shaft 8; a retaining ring 80 fixed on the rotating shaft 8; an inner roller 20 fixed on the retaining ring 80; Outer cylinder 40 around the circumference and sides, and inner side panel 50, outer side panel 60, retaining ring 70, and the like.

[0037] As mentioned above, the rotating shaft 8 is provided with a plurality of sleeves 12 rotatable through the shaft frame on both sides, and a plurality of retaining rings 80 are fixed at a certain interval in the center. The plurality of retaining rings 80 are fixed at equal intervals to the plurality of retaining pieces 81 of the rotating shaft 8 , and a plurality of retaining pieces 81 are vertically fixed to the rotating shaft and are fixed at equal intervals.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com