Minesweeper protective clothing that can be put on and taken off quickly

A kind of protective clothing and fast technology, which is applied in the field of mine-sweeping protective clothing, can solve the problems of mine-sweeping protective parts not being waterproof, the overall quality of the suit is large, and the recovery of unfavorable physical strength, etc., to meet the needs of mine-sweeping use, with optimized hand feeling and good energy absorption and the effect of anti-external force characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

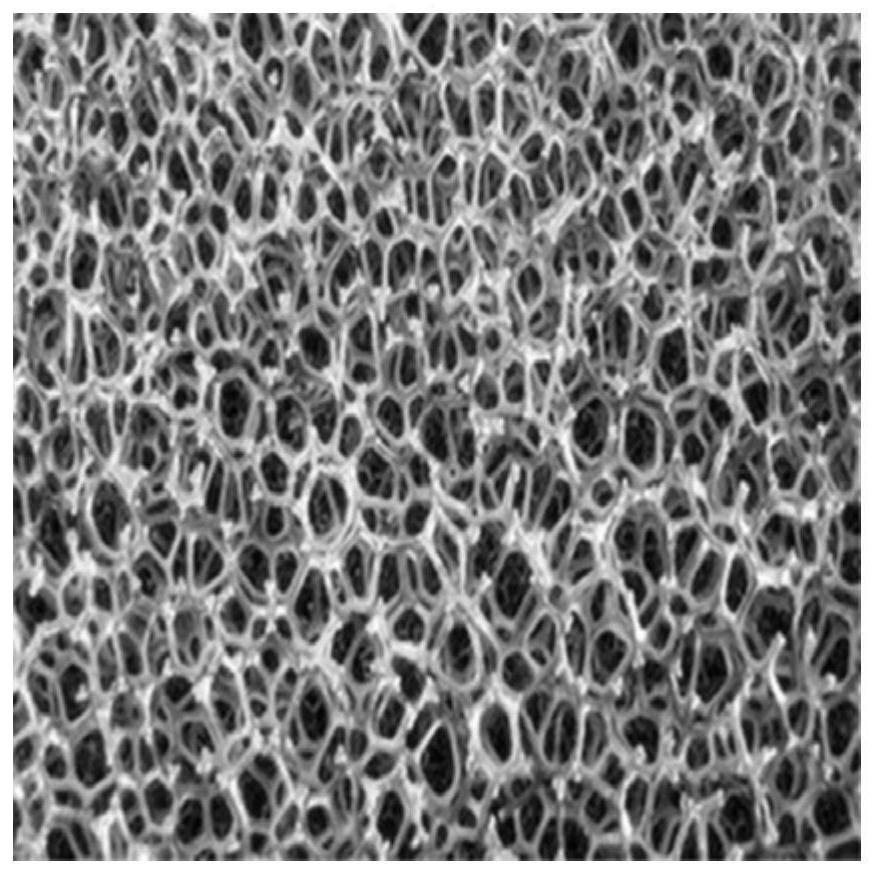

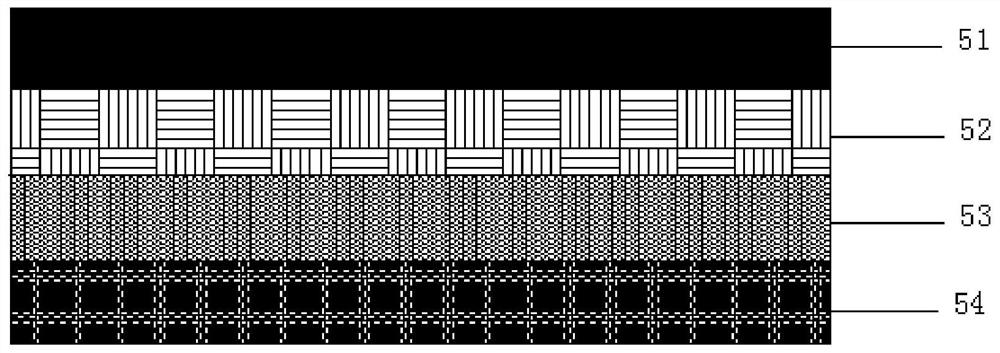

[0029] The reinforced composite middle layer 52 is prepared in the following manner: the three-dimensional porous fibers having a three-dimensional porous through-through structure are pre-impregnated in a tetralin solution containing a modified epoxy resin and a phenolic resin with a total weight percentage of 2% at a temperature of 120° C. Treat for 4 minutes, then cool to room temperature and keep warm for 10 minutes, then use a layout machine to lay up layers tightly in one row, and finally raise the temperature to 140°C under a pressure of 15Mpa and keep it for 25 minutes before cooling to room temperature;

[0030] The impact-resistant layer 53 raw materials include the following components by weight: the reinforced composite intermediate layer 52 raw materials include the following components by weight: 10 parts of polyurethane, 5 parts of bisphenol A type aromatic polycarbonate, 5 parts of polystyrene Ethylene-polyethylene-polybutylene-polystyrene, 2 parts silicone elas...

Embodiment 2

[0032] The reinforced composite middle layer 52 is prepared in the following manner: the three-dimensional porous fiber with a three-dimensional porous through-structure is pre-impregnated in a tetralin solution containing a modified epoxy resin and a phenolic resin with a total weight percentage of 5% at a temperature of 130°C Treat for 6 minutes, then cool to room temperature and keep warm for 20 minutes, then use a layout machine to lay up layers tightly in one row, and finally raise the temperature to 150°C under a pressure of 25Mpa and keep it warm for 35 minutes before cooling to room temperature;

[0033] The impact-resistant layer 53 raw materials include the following components by weight: the reinforced composite intermediate layer 52 raw materials include the following components by weight: 20 parts of polyurethane, 15 parts of bisphenol A type aromatic polycarbonate, 10 parts of polystyrene Ethylene-polyethylene-polybutylene-polystyrene, 8 parts silicone elastomer, ...

Embodiment 3

[0035] The reinforced composite middle layer 52 is prepared in the following manner: the three-dimensional porous fibers with a three-dimensional porous through-structure are pre-impregnated in a tetralin solution containing a modified epoxy resin and a phenolic resin with a total weight percentage of 5% at a temperature of 120° C. Treat for 4 minutes, then cool to room temperature and keep warm for 20 minutes, then use a layout machine to lay up layers tightly in one row, and finally raise the temperature to 150°C under a pressure of 15Mpa and keep it warm for 25 minutes before cooling to room temperature;

[0036] The impact-resistant layer 53 raw materials include the following components by weight: the reinforced composite intermediate layer 52 raw materials include the following components by weight: 10 parts of polyurethane, 15 parts of bisphenol A type aromatic polycarbonate, 5 parts of polystyrene Ethylene-polyethylene-polybutylene-polystyrene, 8 parts of silicone elast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com