Detection method and comparison method of pole piece response uniformity

A detection method and uniformity technology, applied in the field of detection of electrode reaction uniformity, can solve problems such as large range, battery capacity decline, battery safety problems, etc., and achieve the effect of objective and accurate comparison results and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

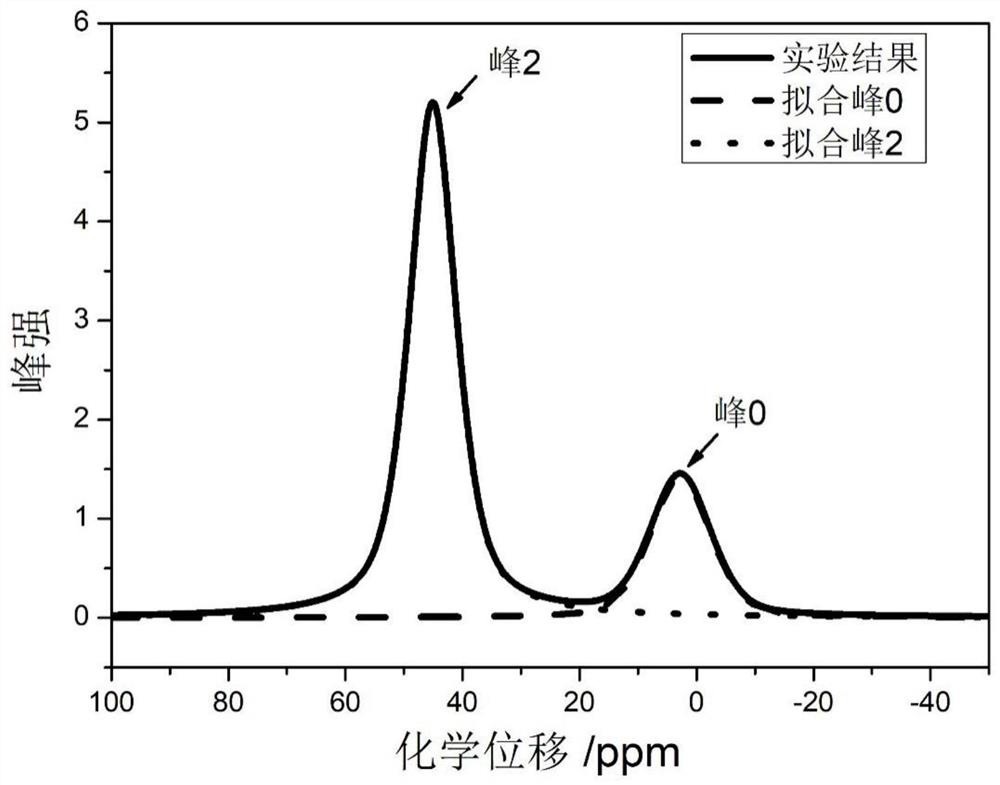

[0050] After the lithium-ion battery with a capacity of 1Ah is discharged to 2.75V with 0.1A, it is charged with a constant current of 0.1A (constant charging rate 0.1C), and the charging capacity is controlled to 0.90Ah, corresponding to a SOC of 90%. Disassemble the battery in a glove box filled with argon (water contentfigure 1 . After peak fitting, only peak 0 and peak 2 exist in the NMR spectrum, and peak 1 does not exist.

Embodiment 2

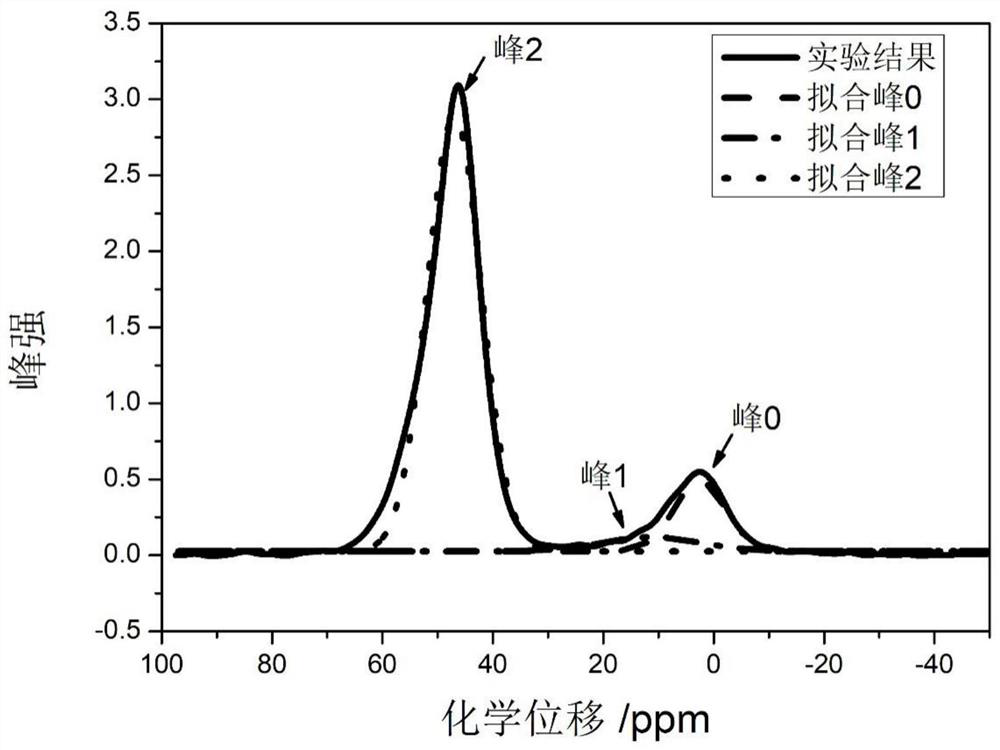

[0052] After the lithium-ion battery with a capacity of 1Ah is discharged to 2.75V with 0.1A, it is charged with a constant current of 0.1A (constant charge rate 0.1C), and the charge capacity is controlled to 0.70Ah, corresponding to SOC of 70%. Disassemble the battery in a glove box filled with argon (water content figure 2 . After peak fitting, there were peak 0, peak 1 and peak 2 in the NMR spectrum at the same time.

Embodiment 3

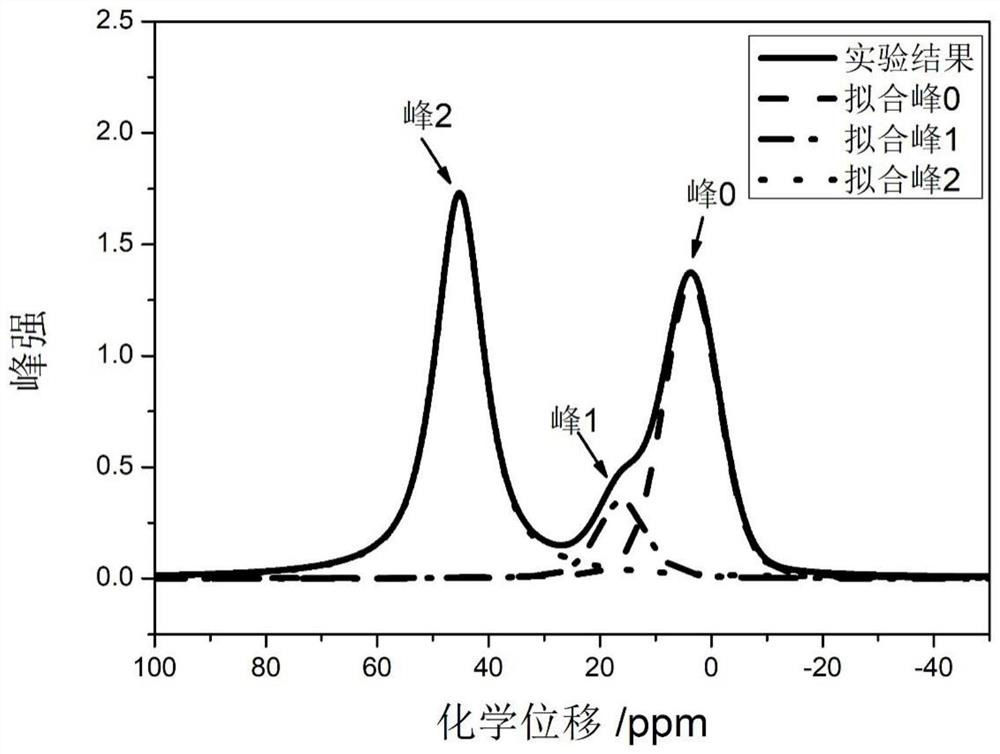

[0054] After the lithium-ion battery with a capacity of 1Ah is discharged to 2.75V with 0.1A, it is charged with a constant current of 0.1A (constant charging rate 0.1C), and the charging capacity is controlled to 0.50Ah, and the corresponding SOC is 50%. Disassemble the battery in a glove box filled with argon (water content image 3 . After peak fitting, there were peak 0, peak 1 and peak 2 in the NMR spectrum at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com