Preparation method of low-temperature sodium-sulfur battery diaphragm and low-temperature sodium-sulfur battery

A sodium-sulfur battery and diaphragm technology, applied in the field of sodium batteries, can solve the problems of flow batteries not being too large, not suitable for intermittent work, and poor battery cycle life, so as to facilitate the transfer of sodium ions and improve safety and reliability , to prevent the effect of penetrating the diaphragm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

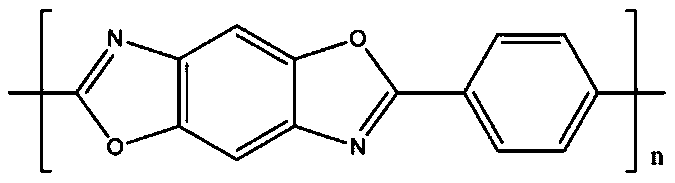

[0041] The 2-methyl-2-propanol solution preparation of embodiment 1 PBO

[0042] Take 100mL of 2-methyl-2-propanol, add 0.78g of PBO resin, heat to 80°C and stir to dissolve to obtain 1wt% PBO in 2-methyl-2-propanol solution.

Embodiment 2

[0043] The N-methylpyrrolidone solution preparation of embodiment 2 PBO

[0044] Take 100mL of N-methylpyrrolidone, add 5.41g of PBO resin, heat to 80°C and stir to dissolve to obtain 5wt% PBO in N-methylpyrrolidone solution.

Embodiment 3

[0045] The formamide solution preparation of embodiment 3 PBO

[0046] Take 100mL formamide, add 10g PBO resin, heat to 80°C and stir to dissolve, to obtain 8.1wt% PBO formamide solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com