Complex and method for producing same

A manufacturing method and complex technology, applied in bismuth compounds, final product manufacturing, tin organic compounds, etc., can solve the obstacles to the development of perovskite compounds, the inability to obtain excellent solar cells, and the difficulty in evaluating the performance of tin-containing perovskite compounds And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0227] Although Examples and the like are shown below to describe the present invention in more detail, the present invention is not limited thereto. In addition, X-ray structural analysis was performed using Sheldrick, G.M. SHELX-97, Program for the Refinement of Crystal Structures; University of Gottingen: Gottingen, Germany, 1997.

reference example 1

[0228] Reference Example 1: Commercially available SnI 2 Sublimation purification

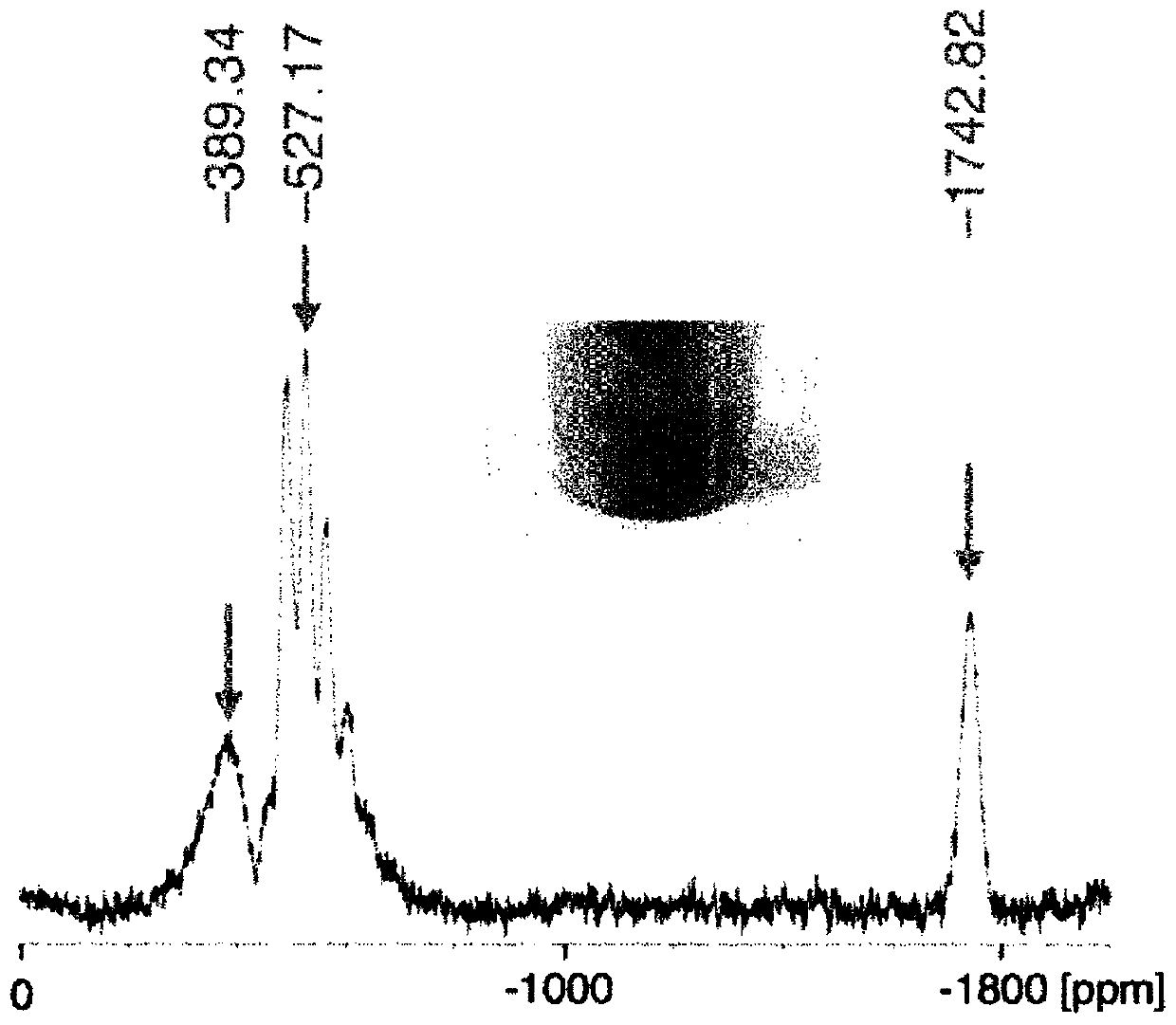

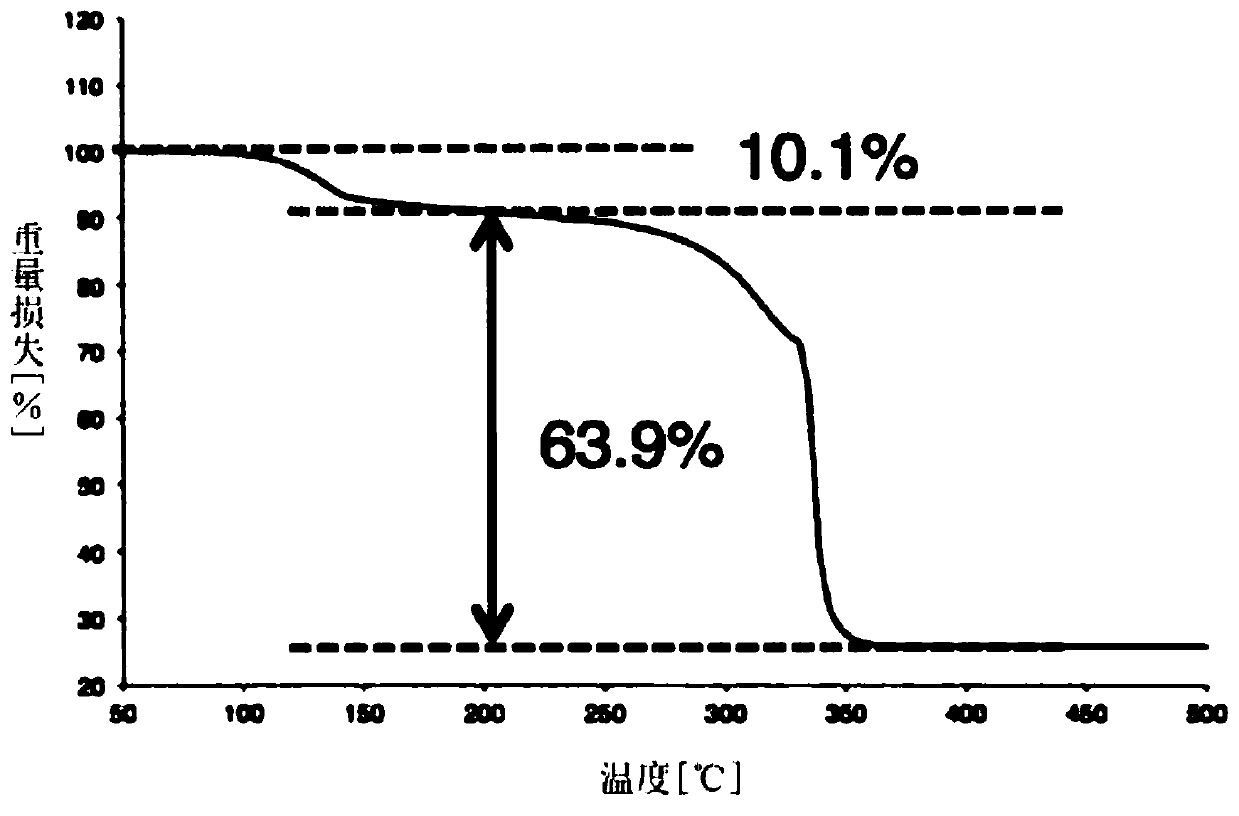

[0229] Figure 1~2 SnI used as raw material is shown 2 (99.9% trace metal basis, manufactured by High Purity Chemical Research Institute Co., Ltd.) 119 Results of Sn MAS NMR and TGA measurements.

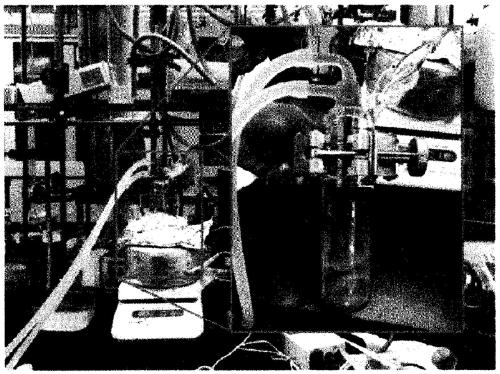

[0230] Then, at image 3 The sublimation purification device shown is put into SnI 2 (99.9% trace metal basis, manufactured by High Purity Chemical Research Institute Co., Ltd.) 10.68 g and reduced pressure (100 Pa) at normal temperature. Put a cover-type electric heater in the sublimation purification device and reduce the pressure at 150°C for 10 hours (0.5mmHg), so as to obtain 2.09g of SnI in red crystals 4 (1st sublime). Thereafter, after cooling to room temperature at 330° C. under reduced pressure (0.5 mmHg) for 22 hours, the container was moved to a glove box (argon gas) to obtain 7.12 g of SnI as a red crystal of the sublimation product. 2 (2nd Sublime). The situation after purifi...

Embodiment 1

[0232] Example 1: SnI 2 ·DMF

[0233] SnI in the glove box 2 (4470 mg, 12 mmol; sublimation-purified product manufactured by Tokyo Chemical Industry Co., Ltd.) was dissolved in ultra-dehydrated DMF (3 mL; manufactured by Wako Pure Chemical Industries, Ltd.) at 50°C. Even after stirring for 1 hour, it was a suspension and not completely dissolved. The remaining insoluble matter was removed by filtration through a PTFE filter, the filtrate was transferred to a test tube with a screw cap, about 15 mL of dichloromethane as an anti-solvent was slowly injected, and recrystallization was performed by the double-layer diffusion method. After 2 days, SnI was obtained as colorless needle crystals 2 DMF. The recovery was 72% (3876 mg, 8.7 mmol). In addition, using the obtained single crystal, its detailed structure was clearly understood by single crystal X-ray crystal structure analysis ( Figure 9 ).

[0234] mp:68.5-75.0℃; 119 Sn MAS NMR(298MHz):δ-391.08( Figure 10 ).Cryst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| rate of recovery | aaaaa | aaaaa |

| rate of recovery | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com