Fortified pig compound feed capable of reducing backfat thickness

A technology of compound feed and thick backfat, applied in animal feed, application, animal husbandry, etc., to achieve the effects of reducing deposition, optimizing body shape, and excellent production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

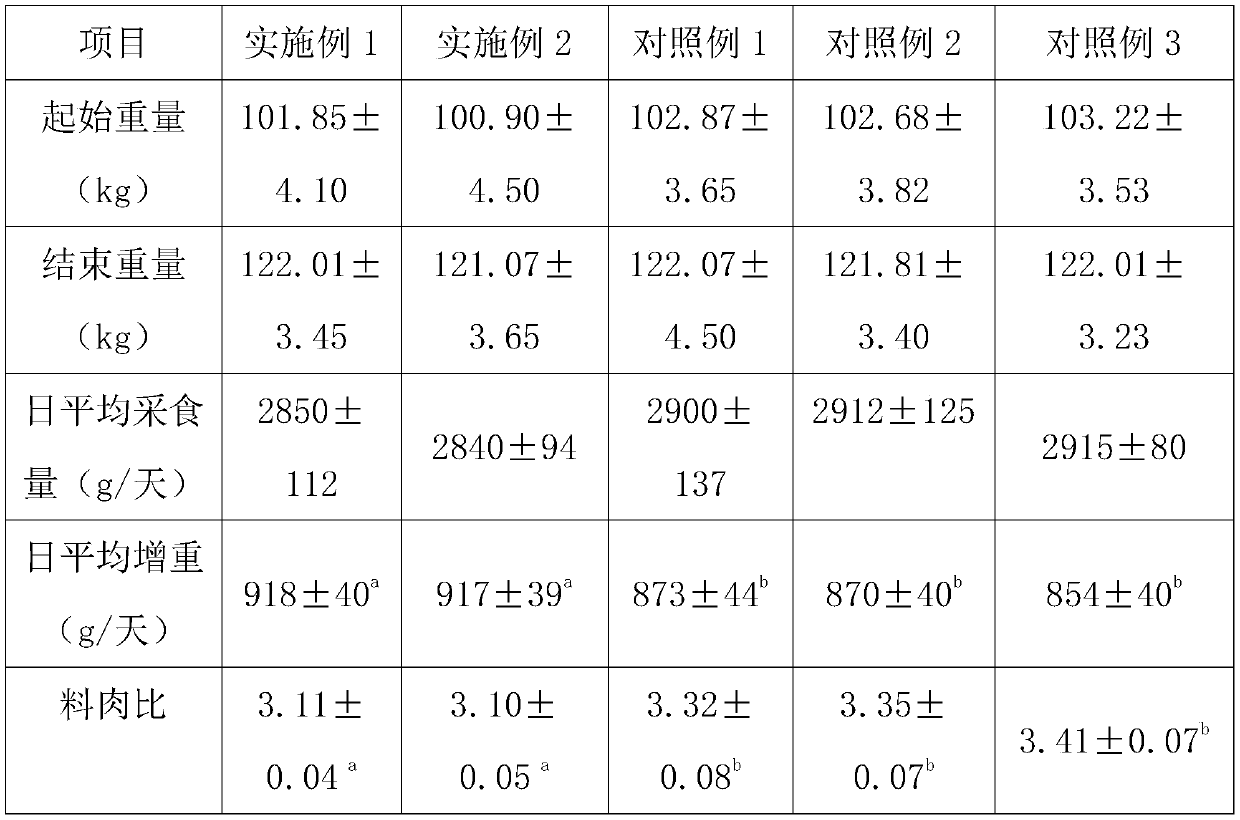

Embodiment 1

[0025] A kind of fortified pig compound feed for reducing backfat thickness, comprising the following raw materials in parts by weight: 45.37 parts of corn, 20 parts of soybean meal, 18 parts of barley, 10 parts of fresh rice bran, 6 parts of premix, 0.56 parts of essential amino acid , 0.04 parts of cysteamine and 0.03 parts of guanidinoacetic acid.

[0026] The preparation method is:

[0027] (1) crushing the corn, the soybean meal and the barley using a 2.5х2.5mm sieve;

[0028] (2) 45.37 parts of corn, 20 parts of soybean meal, 18 parts of barley, 10 parts of fresh rice bran, 6 parts of premix, 0.56 parts of essential amino acids, 0.04 parts of cysteamine and 0.03 parts of guanidinoacetic acid are mixed in proportion;

[0029] (3) Conditioning for 90-110 seconds at a steam pressure of 0.3MPa and a temperature of 80°C;

[0030] (4) Adopt ring membrane granulation with aperture of 4.5mm and compression ratio of 1:10;

[0031] (5) Cool for 10-20 minutes until the temperat...

Embodiment 2

[0040] A kind of strengthened big pig compound feed that reduces backfat thickness, comprises following raw material by weight: 52.09 parts of corn, 15 parts of soybean meal, 12 parts of subflour, 8 parts of fresh rice bran, 6 parts of corn germ cake, 6 parts of prepared Blend, 0.84 parts of essential amino acids, 0.04 parts of cysteamine and 0.03 parts of guanidinoacetic acid.

[0041] The preparation method is:

[0042] (1) pulverizing the corn, the soybean meal and the corn germ meal using a 2.5х2.5mm sieve;

[0043] (2) 52.09 parts of corn, 15 parts of soybean meal, 12 parts of secondary flour, 8 parts of fresh rice bran, 6 parts of corn germ cake, 6 parts of premix, 0.84 parts of essential amino acids in parts by weight , 0.04 parts of cysteamine and 0.03 parts of guanidinoacetic acid are mixed;

[0044] (3) Conditioning for 90-110 seconds at a steam pressure of 0.3MPa and a temperature of 80°C;

[0045] (4) Adopt ring membrane granulation with aperture of 4.5mm and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com