General-type mask

A general-purpose, mask technology, applied in the field of sanitary products, can solve the problems of uncomfortable wearing, unsightly, air leakage, etc., and achieve the effects of comfortable and beautiful wearing and excellent filtration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

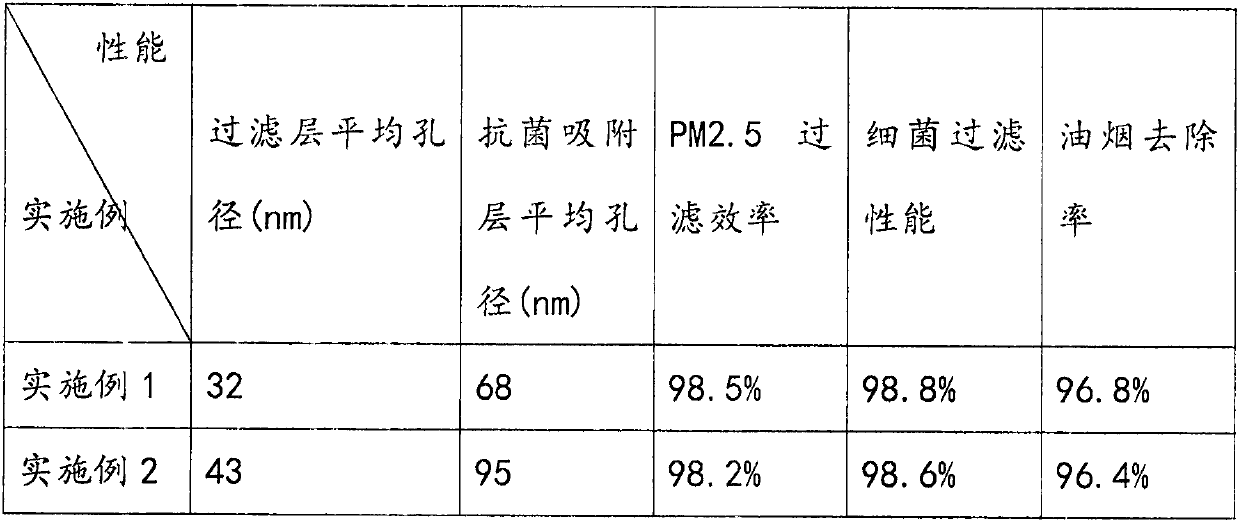

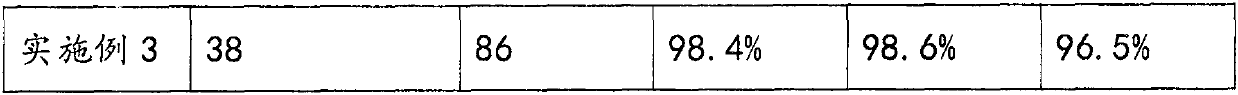

Embodiment 1

[0023]A 0.3 mm thick nickel foam was used as the carrier. The nickel foam was treated as follows: firstly, it was degreased by ultrasonication with acetone for 30 minutes. Then foam nickel was dropped into 6.5mol / L HCl and soaked for 15 minutes, then cleaned with deionized water, and then dried in a 60-degree drying oven for 3 hours.

[0024] The treated foam nickel in 2.5mmol / L of H 2 PtCl 6 ·6H 2 Soak in O solution for 45 minutes. Afterwards, the nickel foam was dried at 85° C. for 8 hours, and then baked in an oven at 300° C. for 3 hours under the condition of feeding hydrogen. Then repeat the above soaking, drying and roasting steps.

[0025] Next, 10 g of activated carbon, 15 g of polyquaternium-10, and 75 g of PVA were added to 120 mL of acetone and dissolved, after which a solution of 2.0 g of ammonium oxalate in 40 mL of water was added and mixed uniformly. The above-mentioned mixture was coated on one side of the above-mentioned nickel foam to obtain an antibact...

Embodiment 2

[0030] A 0.4 mm thick iron-nickel foam was used as the carrier. The iron-nickel foam was treated as follows: firstly, it was degreased by ultrasonication with acetone for 30 minutes. Then put the iron-nickel foam into 6.5mol / L HCl and soak for 15 minutes, then wash it with deionized water, and then dry it in a 60-degree drying oven for 3 hours.

[0031] The treated foamed iron-nickel in 3.5mmol / L RuCl 3 ·3H 2 Soak in O solution for 45 minutes. Afterwards, the iron-nickel foam was dried at 85° C. for 8 hours, and then baked in an oven at 320° C. for 3 hours under the condition of feeding hydrogen. Then repeat the above soaking, drying and roasting steps.

[0032] Next, 20 g of activated carbon, 45 g of polyquaternium-7, and 35 g of ethylene-vinyl acetate copolymer EVA were added in 140 mL of acetone, followed by a solution of 2.5 g of ammonium oxalate in 50 mL of water and mixed well. Coating the mixture on one side of the foamed iron-nickel to obtain an antibacterial adso...

Embodiment 3

[0037] 0.3mm thick copper foam was used as the carrier. The copper foam was treated as follows: first, it was degreased by ultrasonication with acetone for 30 minutes. Then put the copper foam into 6.0mol / L HCl and soak for 15 minutes, then wash it with deionized water, and then dry it in a 60-degree drying oven for 3 hours.

[0038] The treated foam copper in 3.0mmol / L of PdCl 2 2H 2 Soak in O solution for 45 minutes. Afterwards, the copper foam was dried at 90° C. for 8 hours, and then fired in an oven at 350° C. for 3 hours under the condition of feeding hydrogen. Then repeat the above soaking, drying and roasting steps.

[0039] Next, 20 g of activated carbon, 35 g of polyquaternium-7, and 45 g of PET were in 140 mL of acetone, followed by a solution of 2.5 g of ammonium bicarbonate in 50 mL of water and mixed well. The above-mentioned mixture was coated on one side of the above-mentioned foamed copper to obtain an antibacterial adsorption coating. It was then dried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com