Preparation method of Bi2O2SiO3/Bi2O3/BiOBr heterogeneous composite optical material

A composite optical and heterogeneous technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of insufficient response wavelength range and narrow bandgap width, and achieve improved photocatalysis Performance, mild reaction conditions, and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

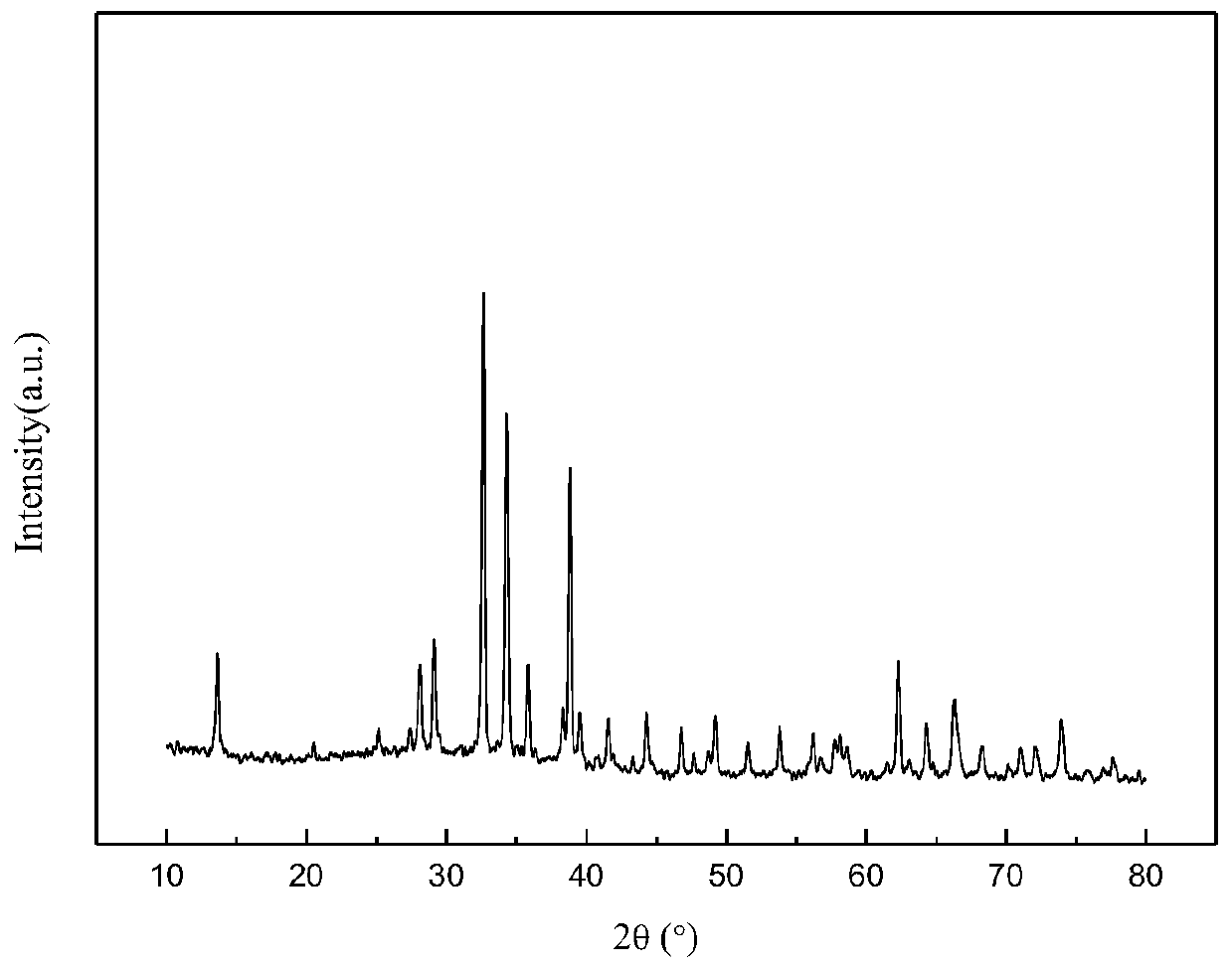

Image

Examples

Embodiment 1

[0026] A Bi 2 o 2 SiO 3 / Bi 2 o 3 The preparation method of / BiOBr heterogeneous composite material, comprises the steps:

[0027] (1) Mix absolute ethanol and deionized water into a beaker at a certain volume ratio, stir on a magnetic stirrer at a slow speed for 5-10 minutes, weigh citric acid into the beaker and stir until completely dissolved; The volume ratio is 1:1, and the concentration of citric acid is 0.5mol / L;

[0028] (2) Weigh a certain amount of bismuth nitrate and add it to the beaker, increase the speed, and stir the powder deposited on the bottom of the beaker with a glass rod every about 10 minutes, seal it with plastic wrap and stir until it is completely dissolved; the concentration of bismuth nitrate 0.2mol / L

[0029] (3) Add a certain amount of ethyl orthosilicate, polyethylene glycol, and sodium lauryl sulfate in turn as a dispersant, and stir until completely dissolved to obtain a precursor solution; the concentration of ethyl orthosilicate is 0.1mo...

Embodiment 2

[0035] A Bi 2 o 2 SiO 3 / Bi 2 o 3 / BiOBr heterogeneous composite optical material preparation method, comprises the steps:

[0036](1) Mix absolute ethanol and deionized water into a beaker at a certain volume ratio, stir on a magnetic stirrer at a slow speed for 5-10 minutes, weigh citric acid into the beaker and stir until completely dissolved; The volume ratio is 1:1.1, and the concentration of citric acid is 0.4mol / L;

[0037] (2) Weigh a certain amount of bismuth nitrate and add it to the beaker, increase the speed, and stir the powder deposited on the bottom of the beaker with a glass rod every about 10 minutes, seal it with plastic wrap and stir until it is completely dissolved; the concentration of bismuth nitrate 0.6mol / L

[0038] (3) Add a certain amount of ethyl orthosilicate, polyethylene glycol, and sodium orthophosphate successively as a dispersant, and stir until completely dissolved to obtain a precursor solution; the concentration of ethyl orthosilicate ...

Embodiment 3

[0045] A Bi 2 o 2 SiO 3 / Bi 2 o 3 / BiOBr heterogeneous composite optical material preparation method, comprises the steps:

[0046] (1) Mix absolute ethanol and deionized water into a beaker at a certain volume ratio, stir on a magnetic stirrer at a slow speed for 5-10 minutes, weigh citric acid into the beaker and stir until completely dissolved; The volume ratio is 1:1.2, and the concentration of citric acid is 0.3mol / L;

[0047] (2) Weigh a certain amount of bismuth nitrate and add it to the beaker, increase the speed, and stir the powder deposited on the bottom of the beaker with a glass rod every about 10 minutes, seal it with plastic wrap and stir until it is completely dissolved; the concentration of bismuth nitrate 0.8mol / L;

[0048] (3) Add a certain amount of ethyl orthosilicate and sodium lauryl sulfate successively as dispersants, and stir until completely dissolved to obtain a precursor solution; the concentration of ethyl orthosilicate is 0.4mol / L, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com