Cylindrical capacitance detecting device for detecting ocean microplastic

A capacitance detection, cylindrical technology, applied in the direction of capacitance measurement, measuring device, measuring electric variable, etc., can solve the problem of large error, achieve the effect of small detection device, accurate counting and measuring size, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

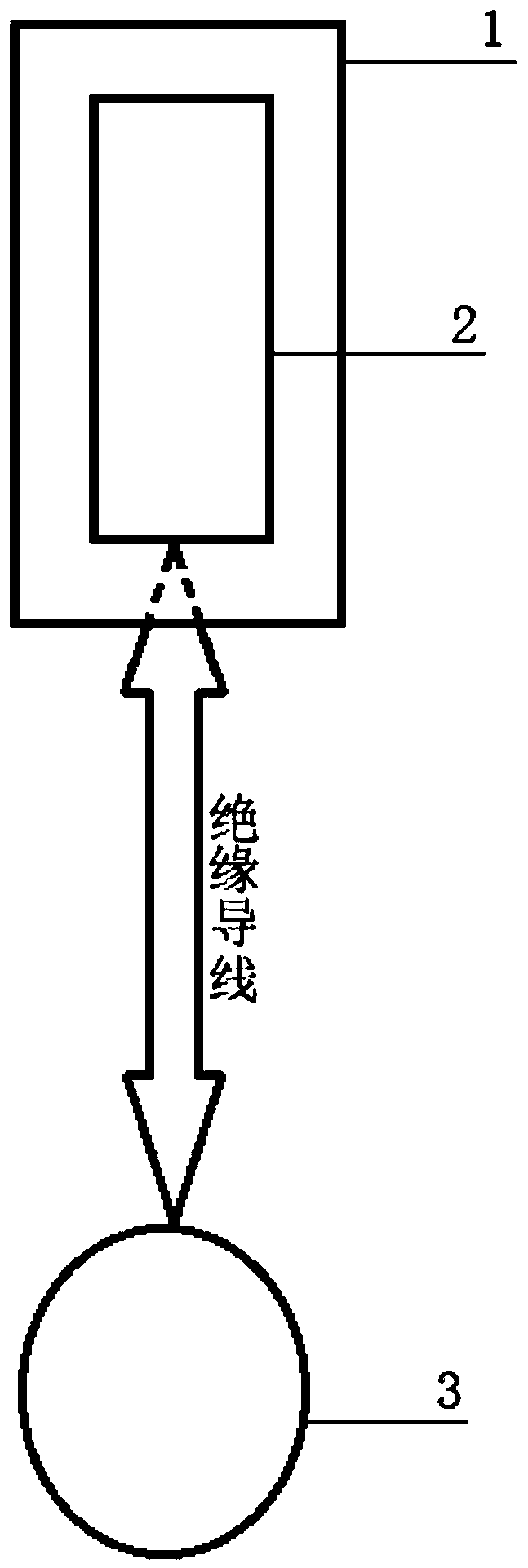

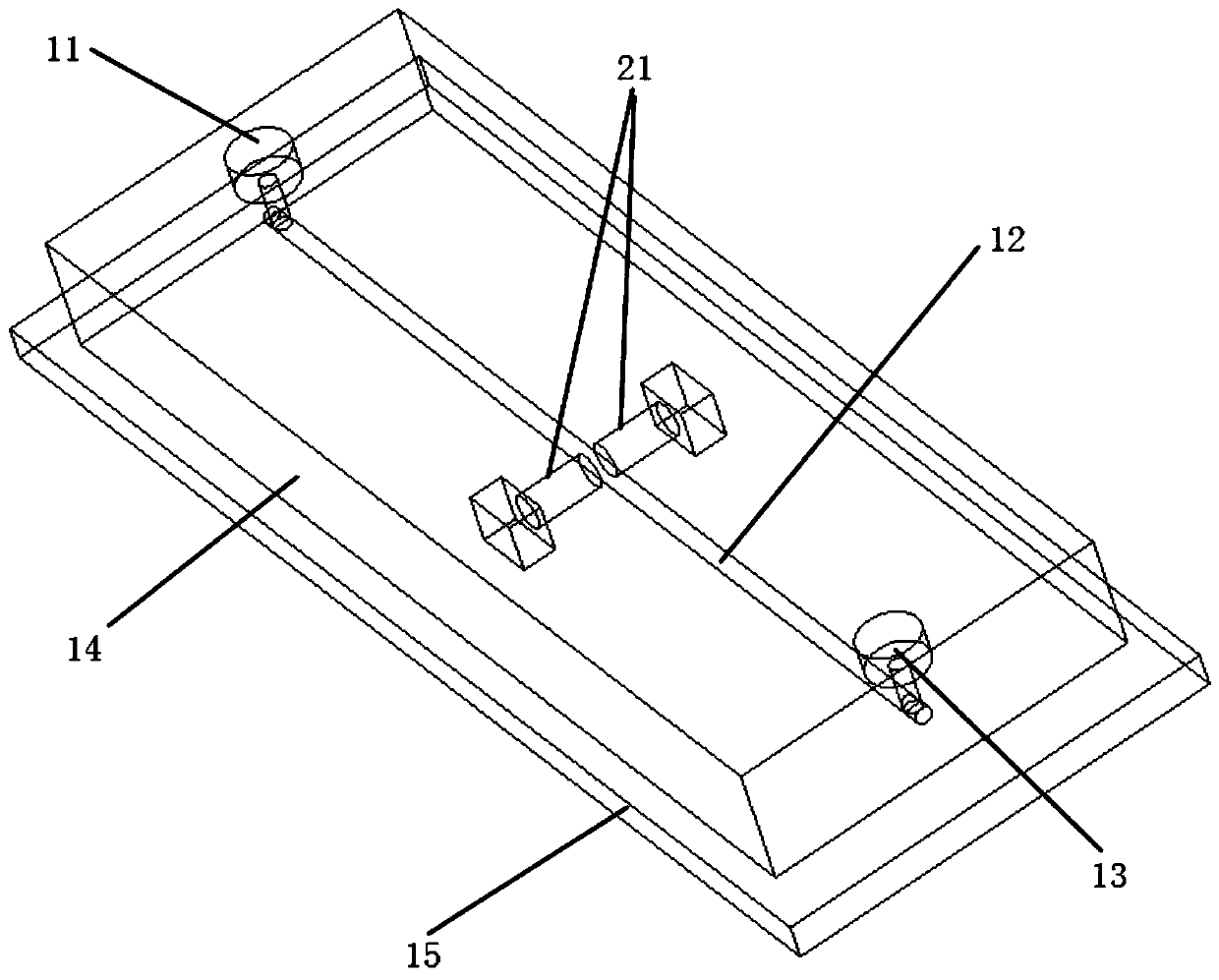

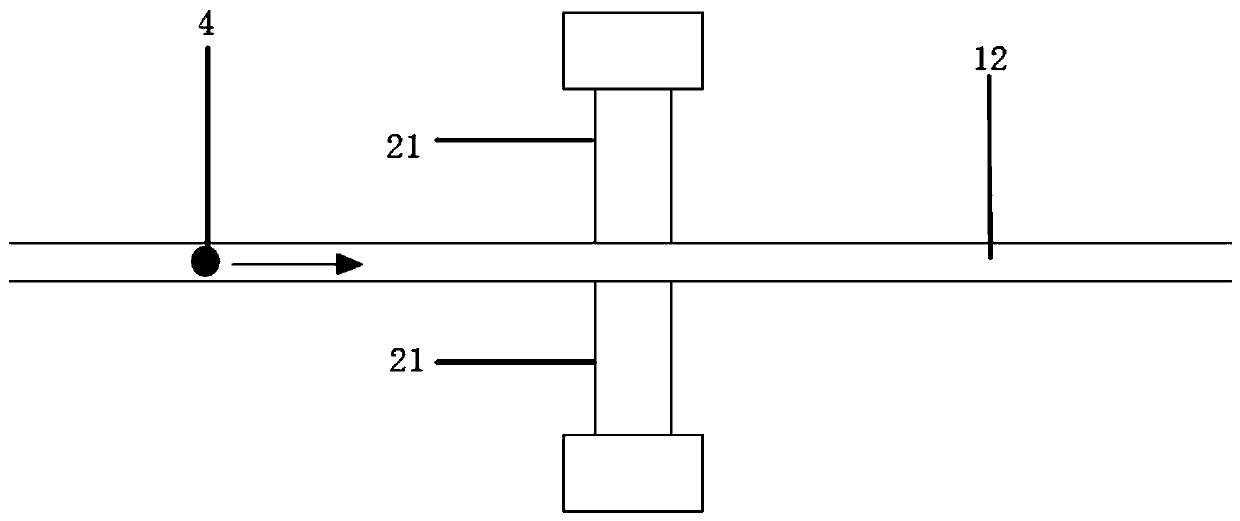

[0047] In this embodiment, a cylindrical capacitive detection device with a distance between two cylindrical capacitive plates set to 300 microns is used, and the excitation unit is connected to the cylindrical capacitive detection unit embedded in the microfluidic detection chip through an insulated wire. The detection microchannel in the microfluidic detection chip passes through the middle of the two cylindrical capacitance plates and is close to the microchannel. When detecting microplastic particles in seawater, the microplastic particles are first driven into the detection device through the sample inlet, flow through the cylindrical capacitor plate through the microchannel, and finally go from the microchannel to the sample outlet. The cylindrical capacitor plate and the LCR are precise The LCR precision meter provides the excitation voltage and frequency, and finally reads the data on the computer. At the same time, the capacitor plate is connected to the microscope to ...

Embodiment 2

[0049] The difference between this embodiment and Embodiment 1 is that in this embodiment, a cylindrical capacitive detection device with a distance between two cylindrical capacitive plates set to 200 microns is used, and the excitation unit is connected by an insulated wire and embedded in a microfluidic device. Detect the cylindrical capacitive detection unit in the chip. The detection microchannel in the microfluidic detection chip passes through the middle of the two cylindrical capacitance plates and is close to the microchannel. When detecting microplastic particles in seawater, the microplastic particles are first driven into the detection device through the sample inlet, flow through the cylindrical capacitor plate through the microchannel, and finally go from the microchannel to the sample outlet. The cylindrical capacitor plate and the LCR are precise The LCR precision meter provides the excitation voltage and frequency, and finally reads the data on the computer. A...

Embodiment 3

[0051] The difference between this embodiment and Embodiment 1 is that in this embodiment, a cylindrical capacitive detection device with a distance between two cylindrical capacitive plates set to 200 microns is used, and the excitation unit is connected by an insulated wire and embedded in a microfluidic device. Detect the cylindrical capacitive detection unit in the chip. The detection microchannel in the microfluidic detection chip passes through the middle of the two cylindrical capacitance plates and is close to the microchannel. When detecting microplastic particles in seawater, the microplastic particles are first driven into the detection device through the sample inlet, flow through the cylindrical capacitor plate through the microchannel, and finally go from the microchannel to the sample outlet. The cylindrical capacitor plate and the LCR are precise The LCR precision meter provides the excitation voltage and frequency, and finally reads the data on the computer. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com