Environment-friendly composite material capable of realizing sorted recovery of metal, plastic and paper, and preparation method thereof

A composite material and environment-friendly technology, applied in the field of packaging materials, can solve the problems of high recycling cost, no fully degradable adhesive layer, and difficult treatment of separated waste liquid, and achieve low cost, good application and market prospects, The effect of green raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

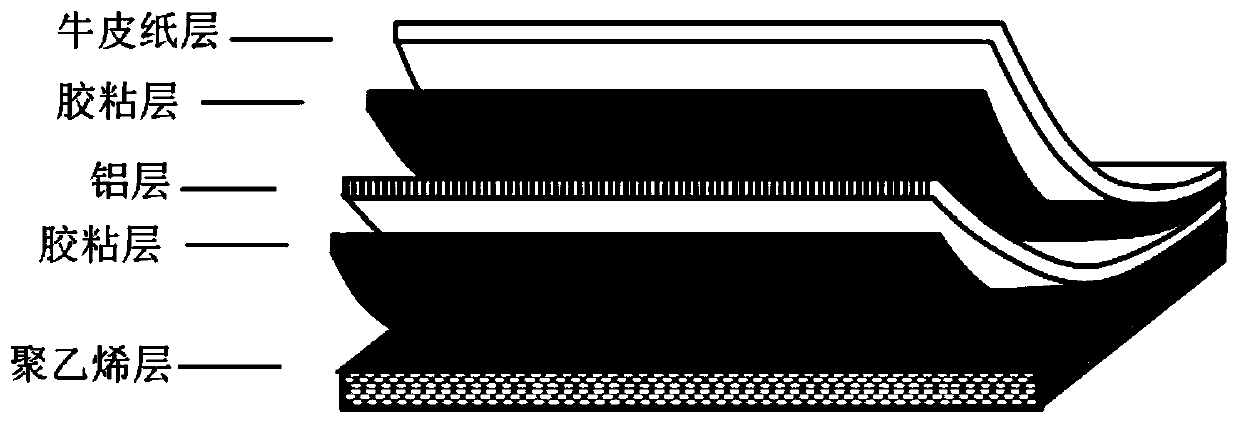

[0054] An environment-friendly composite material, which sequentially comprises a kraft paper layer, an adhesive layer, an aluminum layer, an adhesive layer, and a polyethylene layer; the thickness of the kraft paper layer is 30 μm, the thickness of the adhesive layer is 50 μm, the aluminum The thickness of the layer is 6 μm, and the thickness of the polyethylene layer is 100 μm;

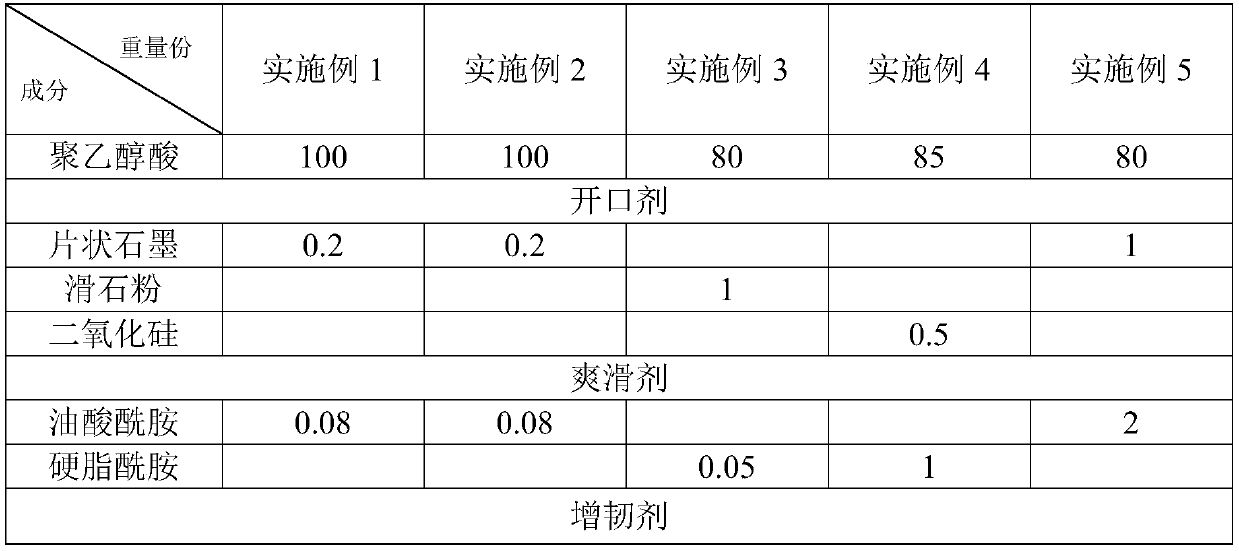

[0055] The adhesive layer is formed of modified polyglycolic acid, and the composition of the modified polyglycolic acid is shown in Table 1.

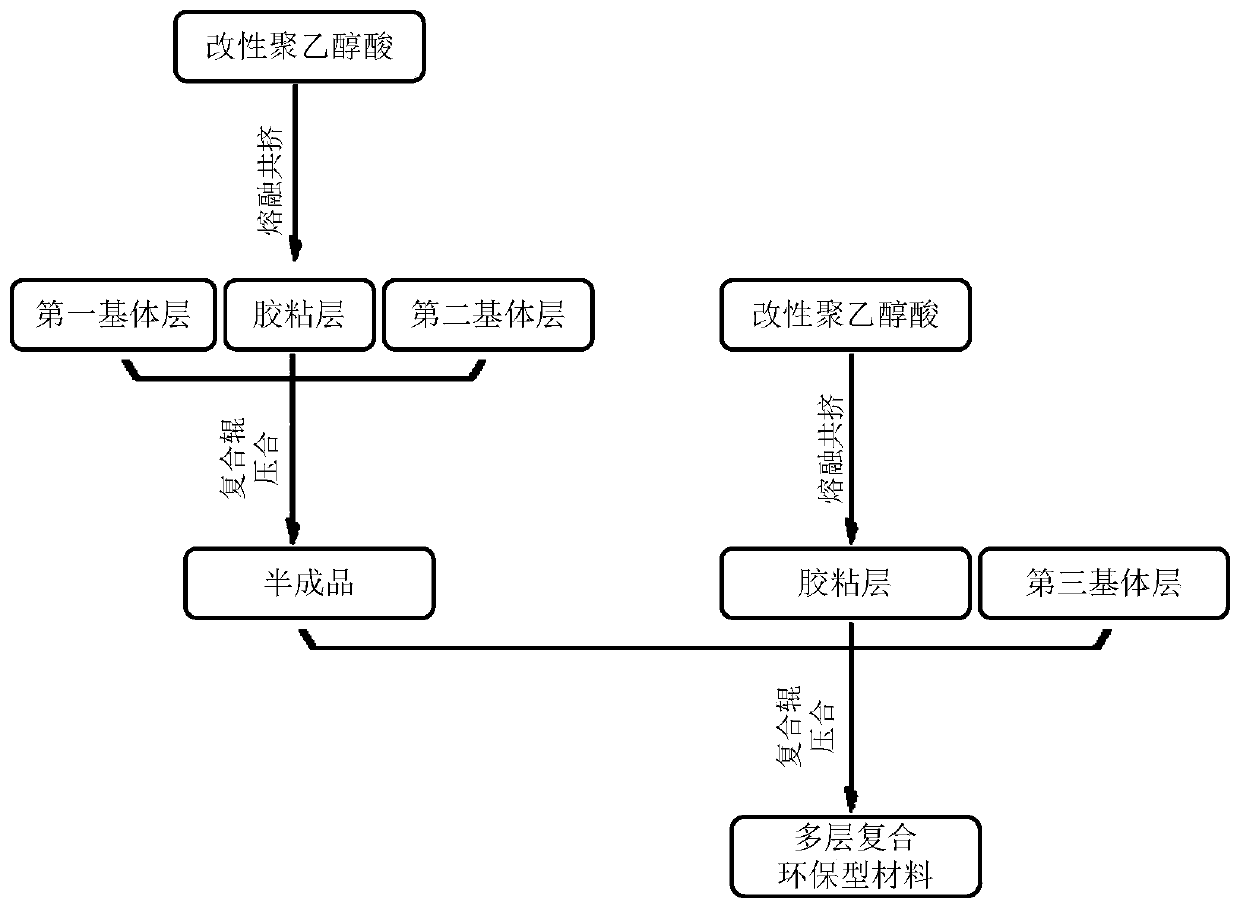

[0056] The preparation method of the above-mentioned environment-friendly composite material includes:

[0057] S1: Input the modified polyglycolic acid pellets into the first sub-screw extruder in the double co-extrusion composite production line, make the pellets form a uniform fluid at a melting temperature of 250-350°C, and then pass through the flat die Extruded to form a cast film as an adhesive layer;

[0058] S2: Stretch and transfer the cast film ...

Embodiment 2

[0063] An environment-friendly composite material, which successively comprises an oil paper layer, an adhesive layer, an aluminum layer, an adhesive layer, and a polyethylene layer; the thickness of the oil paper layer is 100 μm, the thickness of the adhesive layer is 15 μm, the aluminum The thickness of the layer is 7 μm, the thickness of the polyethylene layer is 80 μm;

[0064] The adhesive layer is formed of modified polyglycolic acid, and the composition of the modified polyglycolic acid is shown in Table 1.

[0065] The preparation method of the above-mentioned environment-friendly composite material includes:

[0066] S1: Input the modified polyglycolic acid pellets into the first sub-screw extruder in the double co-extrusion composite production line, make the pellets form a uniform fluid at a melting temperature of 250-350°C, and then pass through the flat die Extruded to form a cast film as an adhesive layer;

[0067] S2: Stretch and transfer the cast film obtaine...

Embodiment 3

[0072] An environment-friendly composite material, which successively comprises a cellophane layer, an adhesive layer, an aluminum layer, an adhesive layer, and a polyethylene layer; the thickness of the cellophane layer is 150 μm, the thickness of the adhesive layer is 20 μm, the aluminum The thickness of the layer is 9 μm, and the thickness of the polyethylene layer is 120 μm;

[0073] The adhesive layer is formed of modified polyglycolic acid, and the composition of the modified polyglycolic acid is shown in Table 1.

[0074] The preparation method of the above-mentioned environment-friendly composite material includes:

[0075] S1: Input the modified polyglycolic acid pellets into the first sub-screw extruder in the double co-extrusion composite production line, make the pellets form a uniform fluid at a melting temperature of 250-350°C, and then pass through the flat die Extruded to form a cast film as an adhesive layer;

[0076] S2: Stretch and transfer the cast film o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com