High-toughness silk fibroin gel preparation method

A silk fibroin and high-toughness technology, which is applied in the field of high-toughness gel and its preparation, can solve the problems of damaging the biocompatibility of the gel, achieve the effects of small inflammatory response, improve biological safety, and increase work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

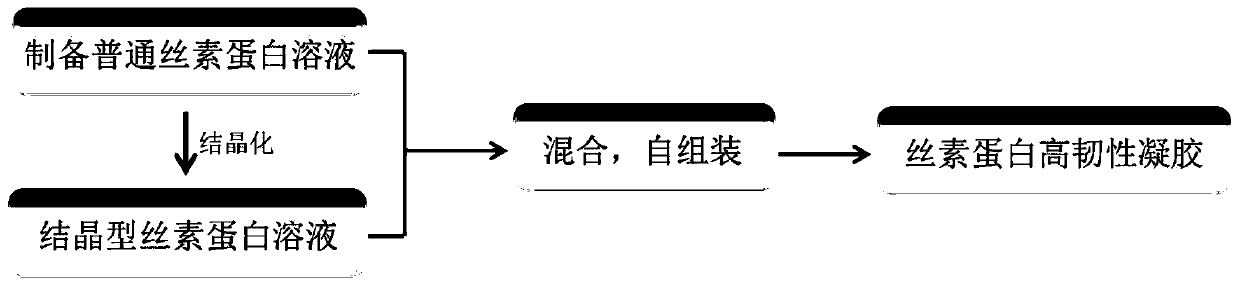

Method used

Image

Examples

Embodiment 1

[0028] Prepare silk fibroin solution. Specifically: put 10g silk in 0.02M Na 2 CO 3 Boil in the solution at 100°C for 30 minutes to remove sericin on the outside of the silk, rinse with deionized water, repeat the above operation 3 times, and then dry the silk at 60°C. 27 g of the degummed silk after the above treatment was weighed and dissolved in 100 mL of LiBr solution with a concentration of 9.3 mol / L, and dissolved at 60° C. for 6 hours. Then use a dialysis bag with a molecular weight cut-off of 3500 to soak in deionized water for dialysis for 3 days, during which the water is changed every two hours to remove LiBr in the solution, thereby obtaining a pure silk fibroin solution.

[0029] After the silk fibroin solution was concentrated to 30% at 60°C, it was diluted to 1% with deionized water, placed in an oven for 24 hours, and then ultrasonicated for 30 seconds with an ultrasonic cell disruptor to obtain a silk fibroin nanofiber solution.

[0030] Adjust the concentr...

Embodiment 2

[0033] The pure silk fibroin solution and the silk fibroin nanofiber solution were prepared by the same method as in Example 1.

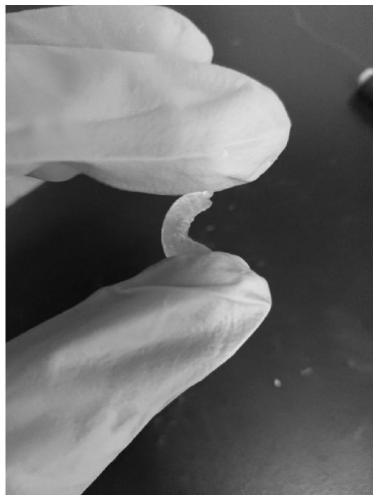

[0034] Adjust the concentration of ordinary silk fibroin solution to 9%, and then mix it with 1% crystalline silk fibroin solution at room temperature at a volume ratio of 1:1, and then suck it into a cylindrical mold, and obtain silk after standing still. Vegan Protein Gel Sticks. Take out the gel stick and bend both ends, the gel stick can be bent without breaking.

[0035] See figure 2 , figure 2 It is the anti-bending condition image of silk fibroin high tenacity gel. From figure 2 It can be seen that the gel has strong toughness.

Embodiment 3

[0037] The pure silk fibroin solution and the crystalline silk fibroin solution were prepared by the same method as in Example 1.

[0038] Dilute the ordinary silk fibroin solution to 3%, and then mix it with 1% crystalline silk fibroin solution at a volume ratio of 1:1 at 60°C to obtain a silk fibroin high-toughness hydrogel.

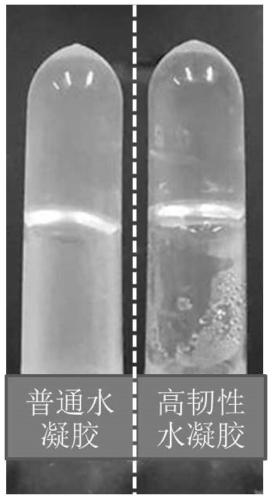

[0039] The 2% ordinary silk fibroin solution is ultrasonically treated, and the ordinary silk fibroin hydrogel is obtained after standing still.

[0040] See image 3 , image 3 It is a comparison chart of silk fibroin high-toughness gel with the same protein concentration described in Example 3 and ordinary silk fibroin gel. The high-toughness gel has higher transparency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com