A high-strength and strain-sensitive polyvinyl alcohol ion hydrogel sensing material and its preparation method and application

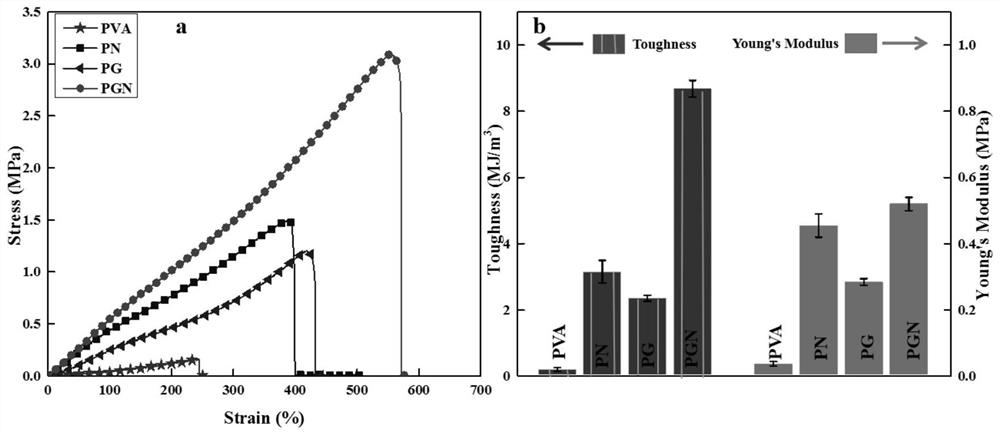

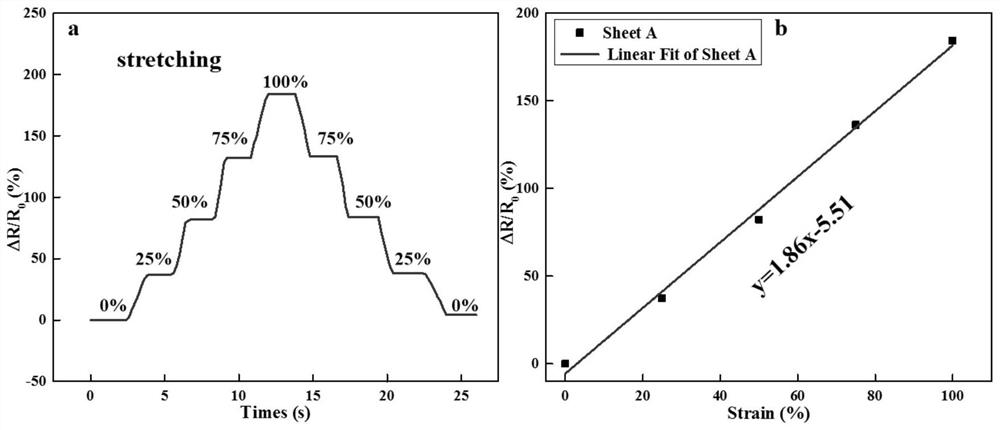

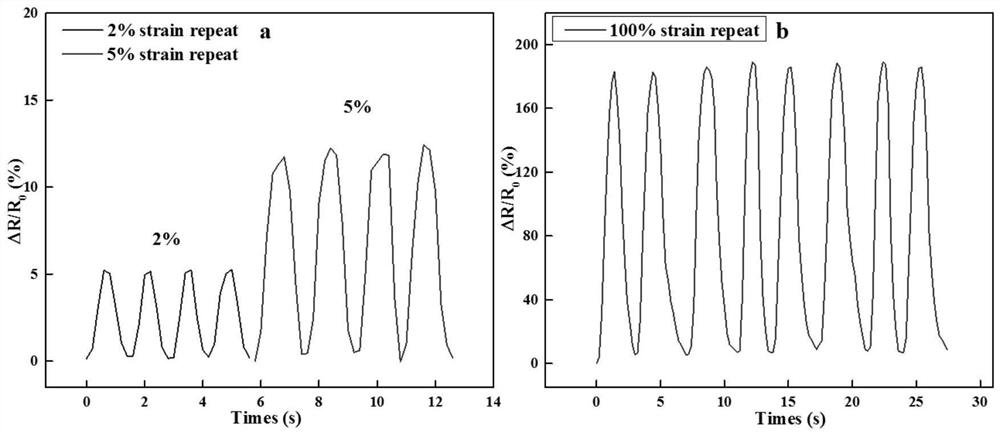

A technology of polyvinyl alcohol and sensing materials, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement devices, etc., can solve the problems of poor strength, toughness and strain sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of a polyvinyl alcohol ion PVA-Glycerol-NaCl (PGN) high-strength hydrogel sensing material of the present embodiment comprises the following steps:

[0036] (1) Add 2.4g of 1797 type polyvinyl alcohol (PVA) to 20g of a mixed solvent composed of deionized water and glycerol (Glycerol), then stir at 100°C for 2.5h to completely dissolve the polyvinyl alcohol to obtain PVA-Glycerol mixed solution; wherein: the mass ratio of deionized water and glycerol is 4:6.

[0037] (2) Transfer the PVA-Glycerol mixed solution obtained in step (1) to a cylindrical mold, and cool it at -20°C for 12 hours, take it out after the cold treatment, and thaw it at room temperature for 3 hours to obtain the PVA-Glycerol hydrogel Glue; Wherein: described cylinder mold height is 50mm, and bottom surface diameter is 3.5mm.

[0038] (3) The PVA-Glycerol hydrogel obtained in step (2) was fully soaked in a saturated sodium chloride (NaCl) solution for 2 hours to obtain a PVA-Gl...

Embodiment 2

[0040] The preparation method of a polyvinyl alcohol ion PVA-Glycerol-NaCl (PGN) high-strength hydrogel sensing material of the present embodiment comprises the following steps:

[0041](1) Add 3g of 1797-type polyvinyl alcohol (PVA) to 36g of a mixed solvent composed of deionized water and glycerol (Glycerol), and then stir at 95°C for 2.5h to completely dissolve the polyvinyl alcohol to obtain PVA - Glycerol mixed solution; wherein: the mass ratio of deionized water and glycerin is 7:3.

[0042] (2) Transfer the PVA-Glycerol mixed solution obtained in step (1) to a cylindrical mold, and cool it at -20°C for 15 hours, take it out after the cold treatment, and thaw it at room temperature for 2 hours to obtain the PVA-Glycerol hydrogel Glue; Wherein: described cylinder mold height is 50mm, and bottom surface diameter is 3.5mm.

[0043] (3) The PVA-Glycerol hydrogel obtained in step (2) was fully soaked in a saturated sodium chloride (NaCl) solution for 2 hours to obtain a PVA-...

Embodiment 3

[0045] The preparation method of a polyvinyl alcohol ion PVA-Glycerol-NaCl (PGN) high-strength hydrogel sensing material of the present embodiment comprises the following steps:

[0046] (1) Add 6g of 1797-type polyvinyl alcohol (PVA) to 50g of a mixed solvent composed of deionized water and glycerol (Glycerol), and then stir at 100°C for 4 hours to completely dissolve the polyvinyl alcohol to obtain PVA- Glycerol mixed solution; wherein: the mass ratio of the deionized water and glycerin is 3:7;

[0047] (2) Transfer the PVA-Glycerol mixed solution obtained in step (1) to a cylindrical mold, and cool it at 0°C for 24 hours, take it out after the cold treatment, and thaw it at room temperature for 2 hours to obtain a PVA-Glycerol hydrogel ; Wherein: the height of the cylinder mold is 50mm, and the diameter of the bottom surface is 3.5mm.

[0048] (3) The PVA-Glycerol hydrogel obtained in step (2) was fully soaked in a saturated sodium chloride (NaCl) solution for 4 hours to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com