High-adhesion silane-modified polyether sealant for prefabricated building and preparation method of sealant

A technology for silane-modified polyether and construction, applied in polyether adhesives, non-polymer adhesive additives, adhesives, etc., can solve problems such as high bonding strength and fracture, and achieve simple and convenient preparation process The effect of using and solving the problem of fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] The present invention also provides the above-mentioned preparation method of the modified polyether sealant for prefabricated buildings with high adhesiveness, which is characterized by comprising the following steps:

[0066] Component A and Component B are prepared, and the order of preparing Component A and Component B is not limited;

[0067] The preparation method of component A is as follows: adding nano-calcium carbonate, heavy calcium carbonate and amino-terminated polyether to the reaction kettle, blending for 1-2 hours under vacuum conditions, and then adding silane-modified polyether polymer, bicarbonate Joint agent I, vinyltrimethoxysilane, thixotropic agent and anti-aging agent are blended under vacuum conditions for 0.5 to 1 hour to obtain component A;

[0068] The preparation method of component B is as follows: adding epoxy resin, flexible diluent, coupling agent II, and catalyst into the reaction kettle, and blending for 1-2 hours under vacuum conditio...

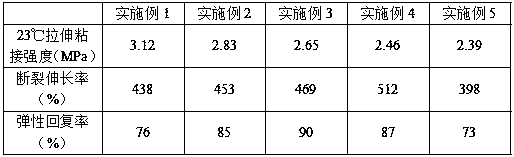

Embodiment 1

[0072] 5 parts of amino-terminated polyether T-3000, 20 parts of nano calcium carbonate, and 30 parts of heavy calcium carbonate were dehydrated and blended for 1 hour in a vacuum state, and then 50 parts of silane-modified polyether polymer 201S, 3 parts of Gamma-aminopropyltrimethoxysilane, 5 parts hydrogenated castor oil, 1 part amine light stabilizer RIASORB UV-770 and 1 part phenolic antioxidant RIANOX 245 and 1 part vinyltrimethoxysilane mixture, in vacuum Dewatering and blending for 0.5 hours to obtain component A of the weather-resistant sealant for prefabricated concrete joints; 15 parts of epoxy resin E-44SMF6101, 5 parts of polyethylene glycol diglycidyl ether, 3 parts of 3-(2,3 -Glycidoxy)propyltrimethoxysilane, 2 parts of chelated tin and 1 part of DMP-30 mixed catalyst are blended for 1 hour under vacuum protection to obtain component B of the weather-resistant sealant for prefabricated concrete joints. The A component and the B component are mixed for 15 minutes...

Embodiment 2

[0074] 5 parts of amino-terminated polyether D-2000, 20 parts of nano-calcium carbonate, and 10 parts of heavy calcium carbonate were dehydrated and blended for 2 hours in a vacuum state, and then 40 parts of silane-modified polyether polymer 201S, 3 parts of Gamma-aminopropyltriethoxysilane, 4 parts polyamide wax, 0.5 part amine light stabilizer RIASORB UV-770 and 0.5 part phenolic antioxidant RIANOX 245 and 1 part vinyltriethoxysilane mixture, Dehydration and blending in a vacuum state for 0.7 hours to obtain component A of the weather-resistant sealant for prefabricated concrete joints; 10 parts of epoxy resin SMF170, 2 parts of polypropylene glycol diglycidyl ether, 2 parts of 2-(3,4-ring A mixture of oxycyclohexyl)ethyltriethoxysilane, 1 part of an organic titanium compound and 1 part of DMP-30 was blended for 1 hour under vacuum protection to obtain component B of a weather-resistant sealant for prefabricated concrete joints. The A component and the B component are mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com