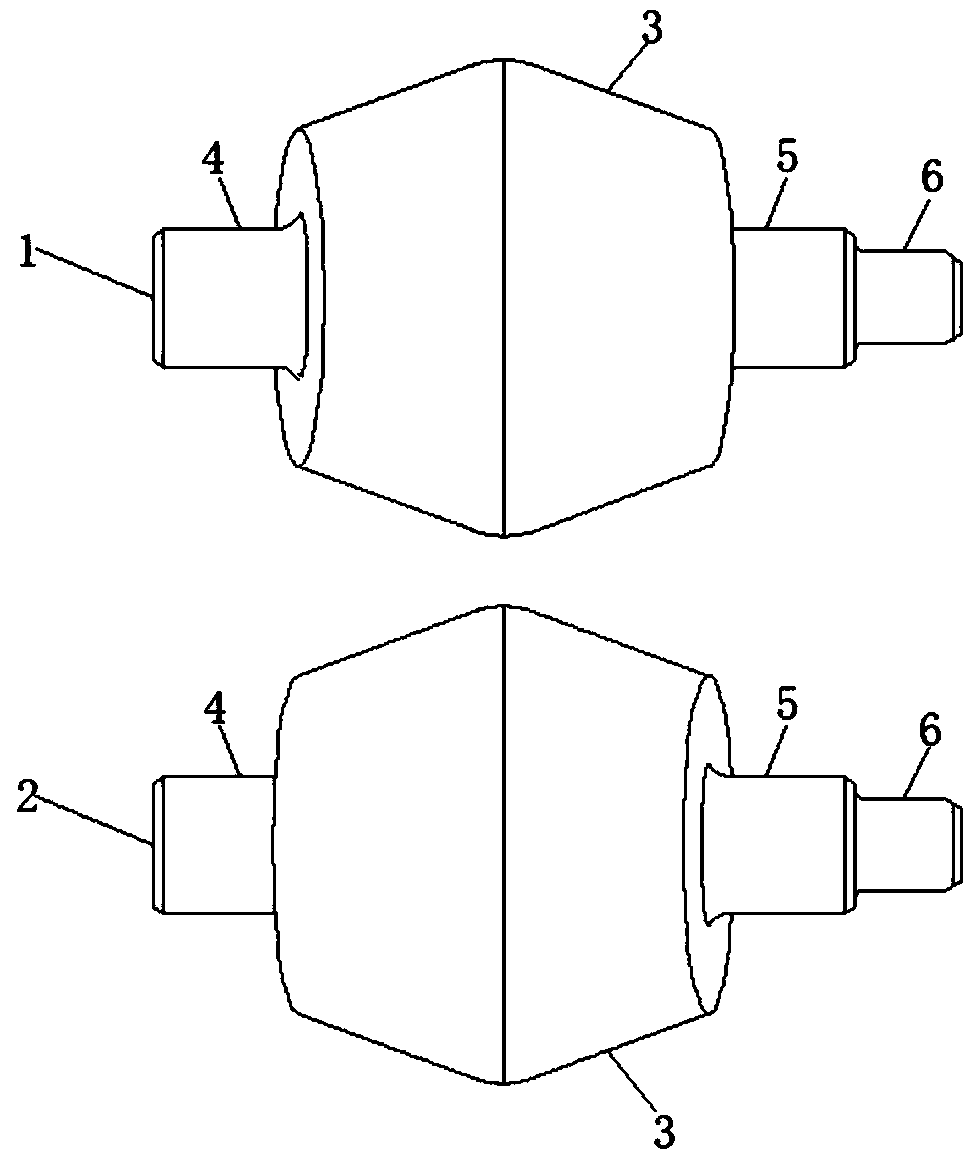

Improved semi-steel material seamless steel pipe slanting roller and processing technology thereof

A technology of seamless steel pipe and processing technology, which is applied in the field of rolls, can solve problems such as short service life, and achieve the effects of improving wear resistance, increasing density, and refining microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, a processing technology of an improved semi-steel seamless steel pipe skew roll, comprising the following steps:

[0030] S1. Determine the chemical composition: the chemical composition of the upper roll 1 and the lower roll 2 is C: 1.35%; Si: 0.35%; Mn: 0.80%; P: 0.010%; S: 0.010%; Ni: 1.50%; Cr : 1.20%; Mo: 0.50%; V: 0.20%;

[0031] S2. Smelting: Melt semi-steel in an intermediate frequency induction furnace, during which a 40-mesh slagging agent is added for slagging (the slagging agent is made by mixing quartz sand, block lime and fluorite powder in a ratio of 7:2.5:0.5), when When the temperature of the molten steel reaches 1450°C and the scum is white, slag occurs, and then when the steel temperature is 1520°C, 2kg / t yttrium-based heavy rare earth molten steel modifier is added, and when the steel temperature reaches 1540°C, the steel is tapped and blown with argon to shake to obtain molten steel ;

[0032] S3. Pouring: calm the molten steel produ...

Embodiment 2

[0035] Embodiment 2, an improved processing technology of semi-steel material seamless steel pipe skew roll, comprising the following steps:

[0036] S1. Determine the chemical composition: the chemical composition of the upper roll 1 and the lower roll 2 is C: 1.40%; Si: 0.55%; Mn: 1.00%; P: 0.020%; S: 0.015%; Ni: 2.50%; Cr : 1.50%; Mo: 0.60%; V: 0.30%;

[0037] S2. Smelting: Melt semi-steel in an intermediate frequency induction furnace, during which a 50-mesh slagging agent is added for slagging (the slagging agent is made by mixing quartz sand, block lime and fluorite powder in a ratio of 7:2.5:0.5), when When the temperature of the molten steel reaches 1450°C and the scum is white, slag occurs, and then 2.5kg / t yttrium-based heavy rare earth molten steel modifier is added when the steel temperature reaches 1520°C, and when the steel temperature reaches 1540°C, the steel is tapped and blown with argon to shake it to obtain molten steel;

[0038] S3. Pouring: calm the molte...

Embodiment 3

[0041] Embodiment 3, an improved processing technology of semi-steel material seamless steel pipe skew roll, comprising the following steps:

[0042] S1. Determine the chemical composition: the chemical composition of the upper roll 1 and the lower roll 2 is C: 1.60%; Si: 0.75%; Mn: 1.50%; P: 0.030%; S: 0.020%; Ni: 3.50%; Cr : 1.80%; Mo: 0.70%; V: 0.4%;

[0043] S2. Smelting: Melt semi-steel in an intermediate frequency induction furnace, during which a 70-mesh slagging agent is added for slagging (the slagging agent is made by mixing quartz sand, lump lime and fluorite powder in a ratio of 7:2.5:0.5), when When the temperature of the molten steel reaches 1450°C and the scum is white, slag occurs, and then 3kg / t yttrium-based heavy rare earth molten steel modifier is added when the steel temperature reaches 1520°C. ;

[0044] S3. Pouring: calm the molten steel produced in step S2 for 12 minutes, pour it into the roll casting mold when the steel temperature reaches the liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com