Production method of electronic-grade glass fiber cloth

A technology of glass fiber cloth and production method, which is applied in fiber treatment, glass furnace equipment, glass manufacturing equipment, etc., and can solve the problem of affecting the mechanical properties, electrical properties and processing properties of copper clad laminates, weakening the tensile strength of glass fibers, and electronic cloth fish problems such as mesh and white spots, to achieve the effect of ensuring excellent performance, improving relative stability, and improving impregnation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

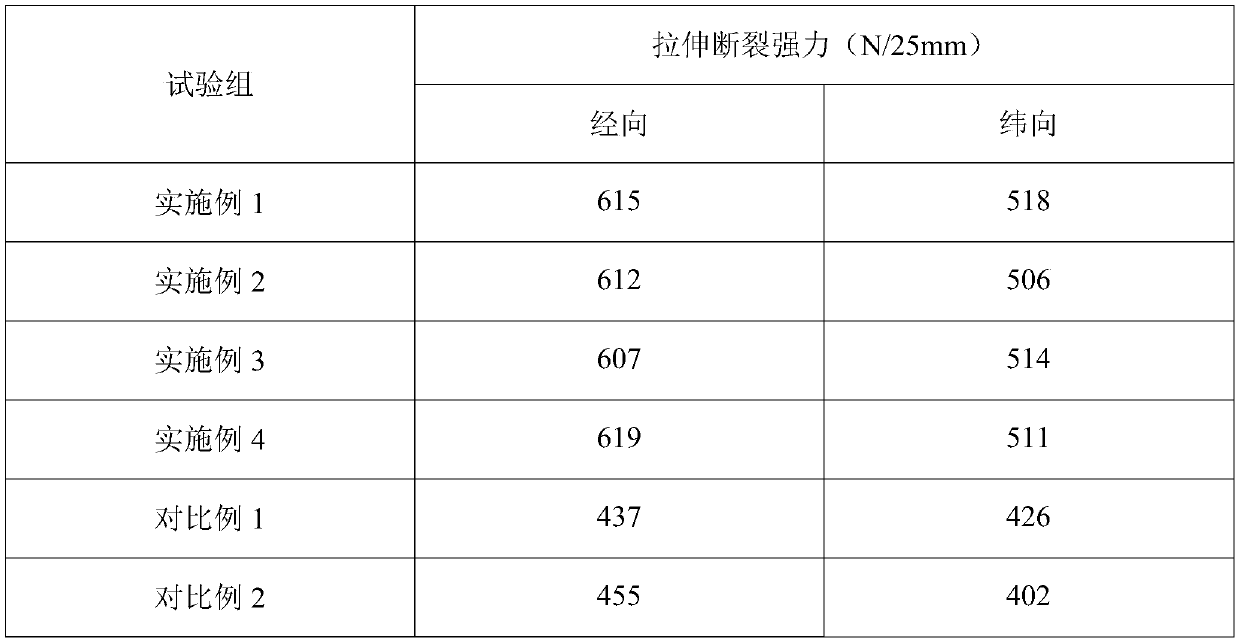

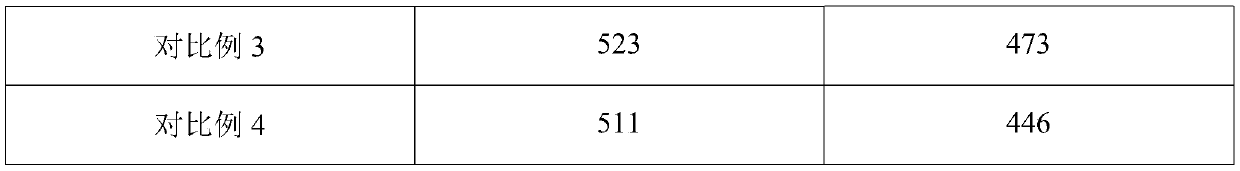

Examples

Embodiment 1

[0042]In this embodiment, the composition of the wetting agent is: 0.06% of quaternary ammonium salt, 5% of bisphenol A epoxy resin (M=8000), 0.3% of isooctyl alcohol, 0.5% of polyurethane emulsion, dodecyl trimethoxy Silane 0.3%, the rest is deionized water;

[0043] The preparation method of wetting agent is as follows:

[0044] S1: Preparation of silane coupling agent solution:

[0045] Put half of the total amount of deionized water in the wetting agent preparation tank, adjust the pH value to about 3.5 with acetic acid, slowly add dodecyltrimethoxysilane at a stirring speed of 150rpm, stir for 40min, the solution is clear, the surface No oil flower, indicating that the hydrolysis is complete, measure the pH value;

[0046] S2: Control the stirring speed of 150rpm, add quaternary ammonium salt, isooctyl alcohol, bisphenol A epoxy resin, polyurethane emulsion, and the remaining deionized water to the prepared silane coupling agent solution in sequence, and adjust the pH v...

Embodiment 2

[0056] In this embodiment, the composition of the wetting agent is: 0.05% of quaternary ammonium salt, 3% of bisphenol A epoxy resin (M=8000), 0.1% of isooctyl alcohol, 0.4% of polyurethane emulsion, dodecyl trimethoxy Silane 0.5%, the rest is deionized water;

[0057] The preparation method of wetting agent is:

[0058] S1: Preparation of silane coupling agent solution: put deionized water with half the total water consumption in the wetting agent preparation tank, adjust the pH value to about 3.0 with acetic acid, slowly add dodecyl trimethoxy at a stirring speed of 50rpm Silane, stir for 30 minutes, the solution is clear, no oily flowers on the surface, indicating that the hydrolysis is complete, measure the pH value;

[0059] S2: Control the stirring speed of 100rpm, add quaternary ammonium salt, isooctyl alcohol, bisphenol A epoxy resin, polyurethane emulsion, and the remaining deionized water to the prepared silane coupling agent solution in sequence, and adjust the pH ...

Embodiment 3

[0069] In this embodiment, the composition of the wetting agent is: 0.1% of quaternary ammonium salt, 6% of bisphenol A epoxy resin (M=8000), 0.5% of isooctyl alcohol, 0.6% of polyurethane emulsion, cetyl trimethoxy Silane 0.5%, the rest is deionized water;

[0070] The preparation method of wetting agent is as follows:

[0071] S1: Preparation of silane coupling agent solution:

[0072] Put half of the total amount of deionized water into the wetting agent preparation tank, adjust the pH value to about 4.0 with acetic acid, slowly add hexadecyltrimethoxysilane at a stirring speed of 200rpm, and stir for 60min. The solution is clear and the surface No oil flower, indicating that the hydrolysis is complete, measure the pH value;

[0073] S2: Control the stirring speed of 200rpm, add quaternary ammonium salt, isooctyl alcohol, bisphenol A epoxy resin, polyurethane emulsion, and the remaining deionized water to the prepared silane coupling agent solution in sequence, and adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com