Optical fiber liquid level sensor and optical fiber liquid level sensing method

A technology of liquid level sensor and optical fiber, which is applied in the directions of liquid level indicators, instruments, machines/engines, etc. It can solve the problems of safety considerations such as the application restrictions of electric measuring devices, and achieve the effect of low cost and adjustable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

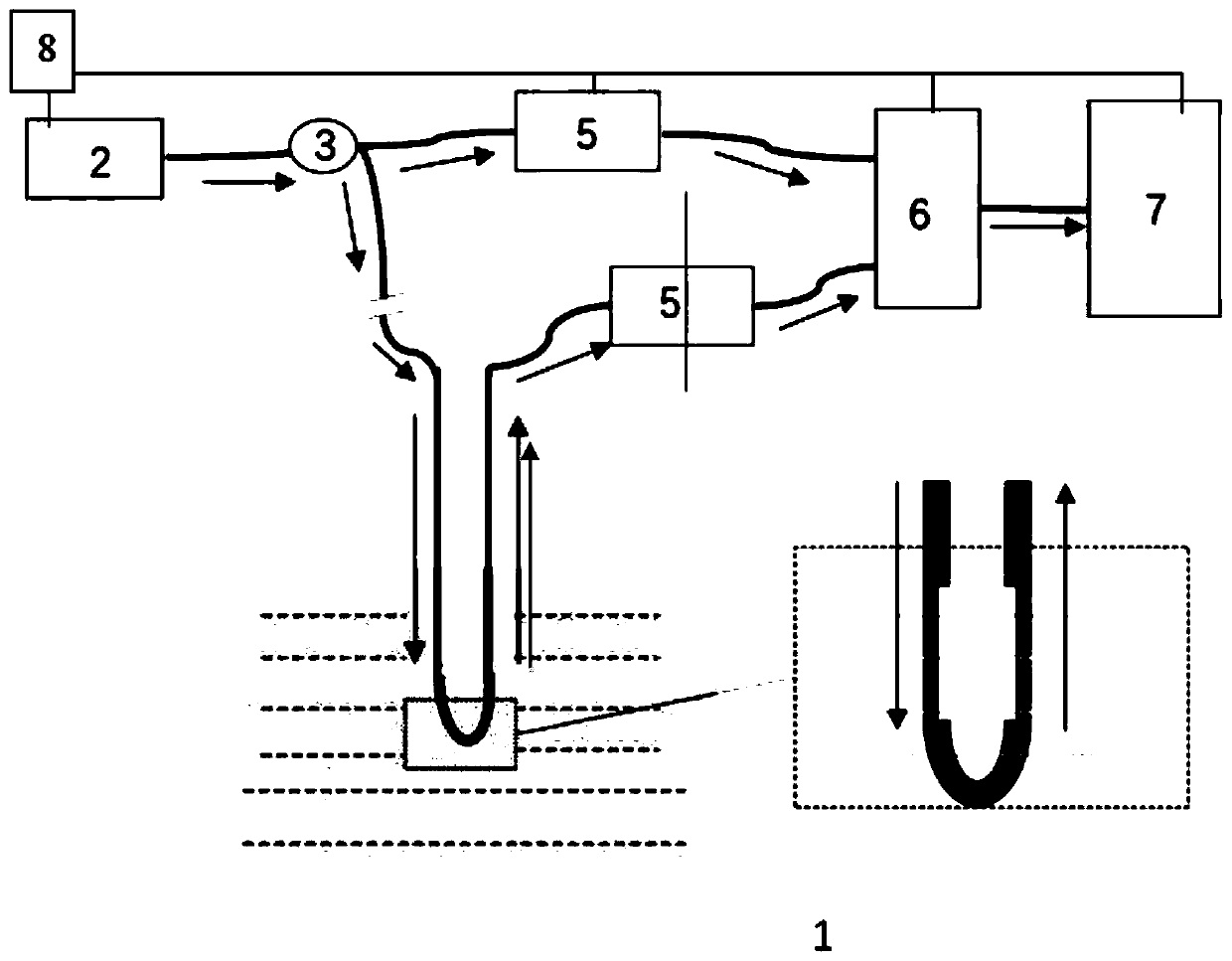

[0018] Such as figure 1 As shown, the arrow indicates the transmission direction of light or electrical signal, the present invention is realized in this way, it comprises a U-shaped optical fiber probe 1 that has been removed part of the cladding and is immersed in the liquid, and a monochromatic light source 2, Y Type optical coupling beam splitter 3, two photoelectric converters 5 for proportional detection, signal conditioning circuit 6, output and display module 7. The light that light source 2 outputs is coupled to Y-type optical coupling beam splitter 3, and one connects photoelectric converter 5 after the power ratio beam by 50:50, and the measured optical power is I 0 ; The other is connected to the input end of fiber optic probe 1. The U-shaped bending part of the fiber optic probe 1 has been uniformly and continuously removed part of the fiber cladding, and light will leak outward when it is transmitted to the fiber part where the cladding is removed. The U-shaped ...

Embodiment 2

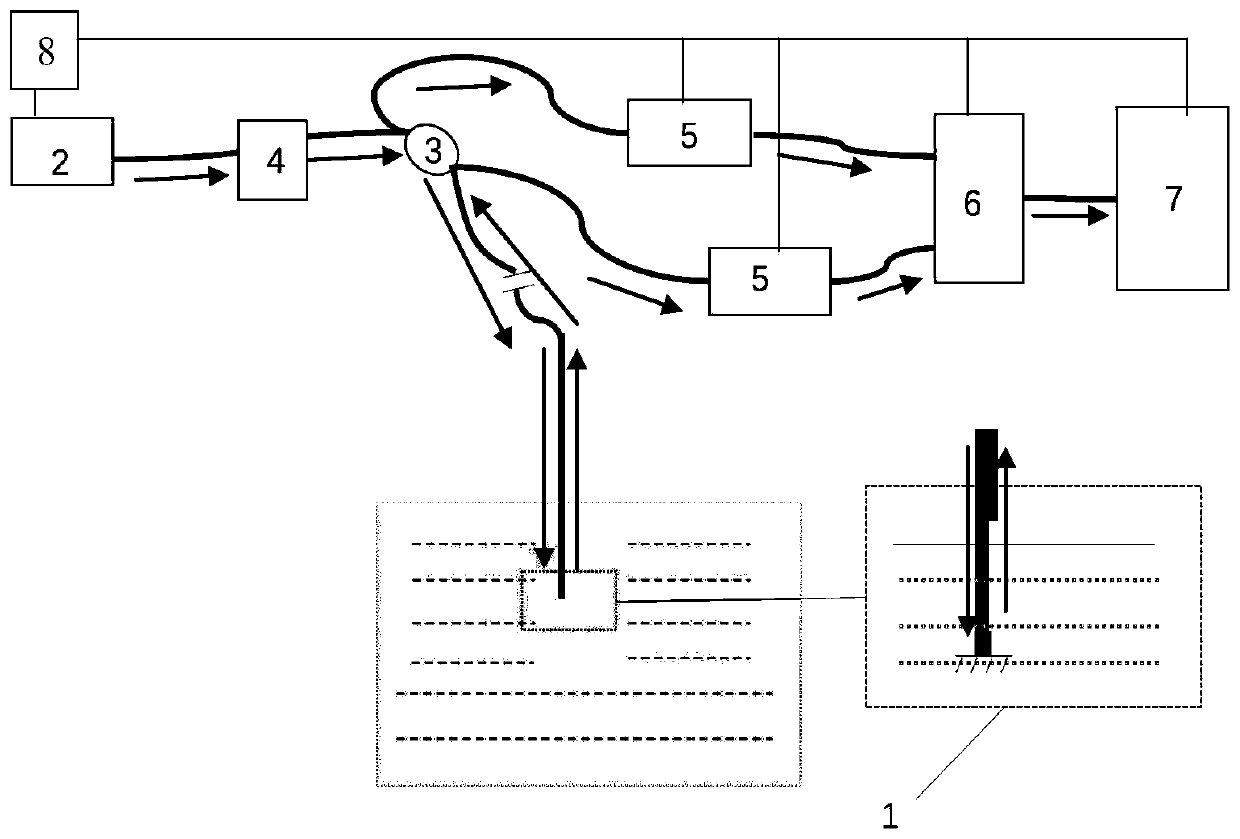

[0021] Such as figure 2 As shown, the arrow indicates the transmission direction of light or electrical signals. The device of the present invention includes an optical fiber probe 1 that has been removed part of the cladding near the end face and is submerged in the liquid upright at one end, and a monochromatic light source 2, 2 ×2 type optical coupling beam splitter 3, optical isolator 4, two photoelectric converters 5 for proportional detection, signal conditioning circuit 6, output and display module 7. The light output by the light source 2 is connected to one of the input ends of the optical coupling beam splitter 3 after the optical isolator 4, and the output end of the beam splitter is connected to the photoelectric converter 5, and the measured optical power is I 0 ; The other output end is connected to one end of fiber optic probe 1. The other end of the optical fiber probe 1 is evenly and continuously removed part of the fiber cladding, and a reflector is pasted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com