Latex dispersion preparation method and kit

A technology of dispersion and latex, which is applied in the field of dispersion of latex for protein carriers, can solve the problems of low production efficiency and long production time, and achieve the effects of increased production capacity, good detection sensitivity and improved working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

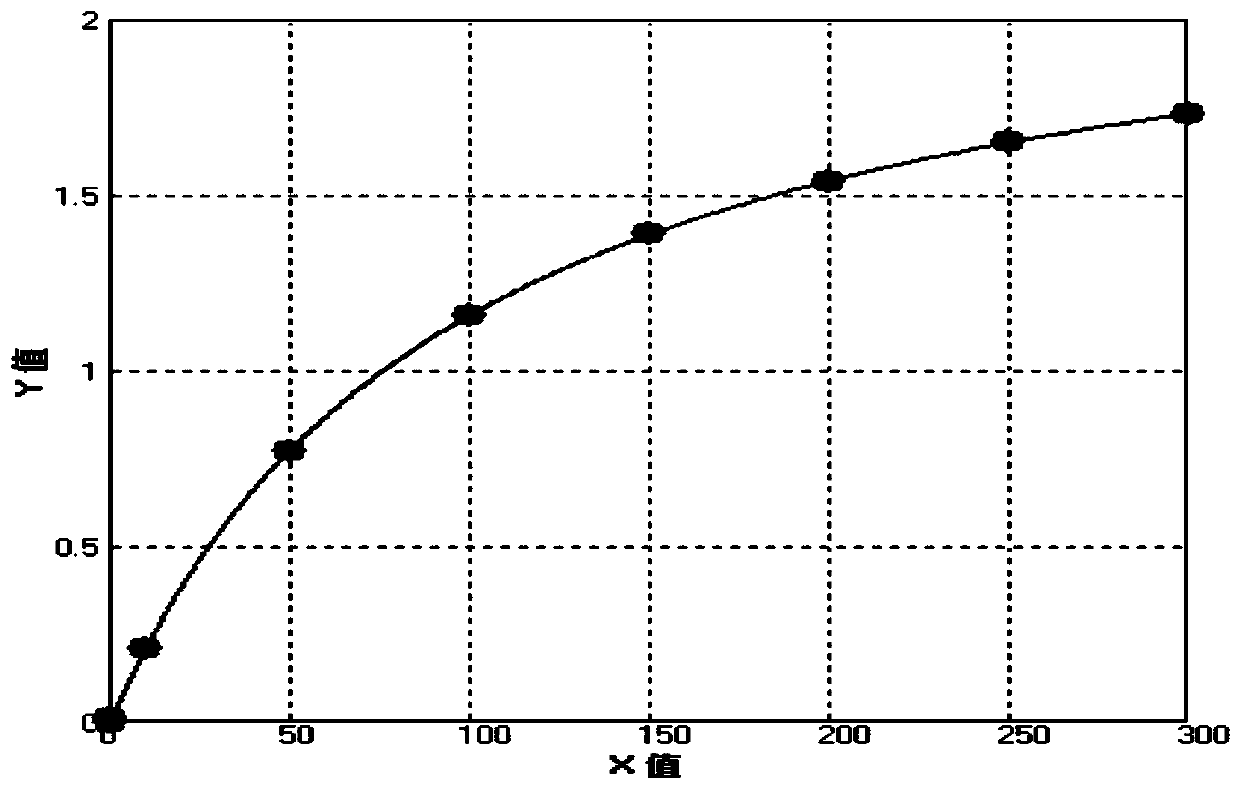

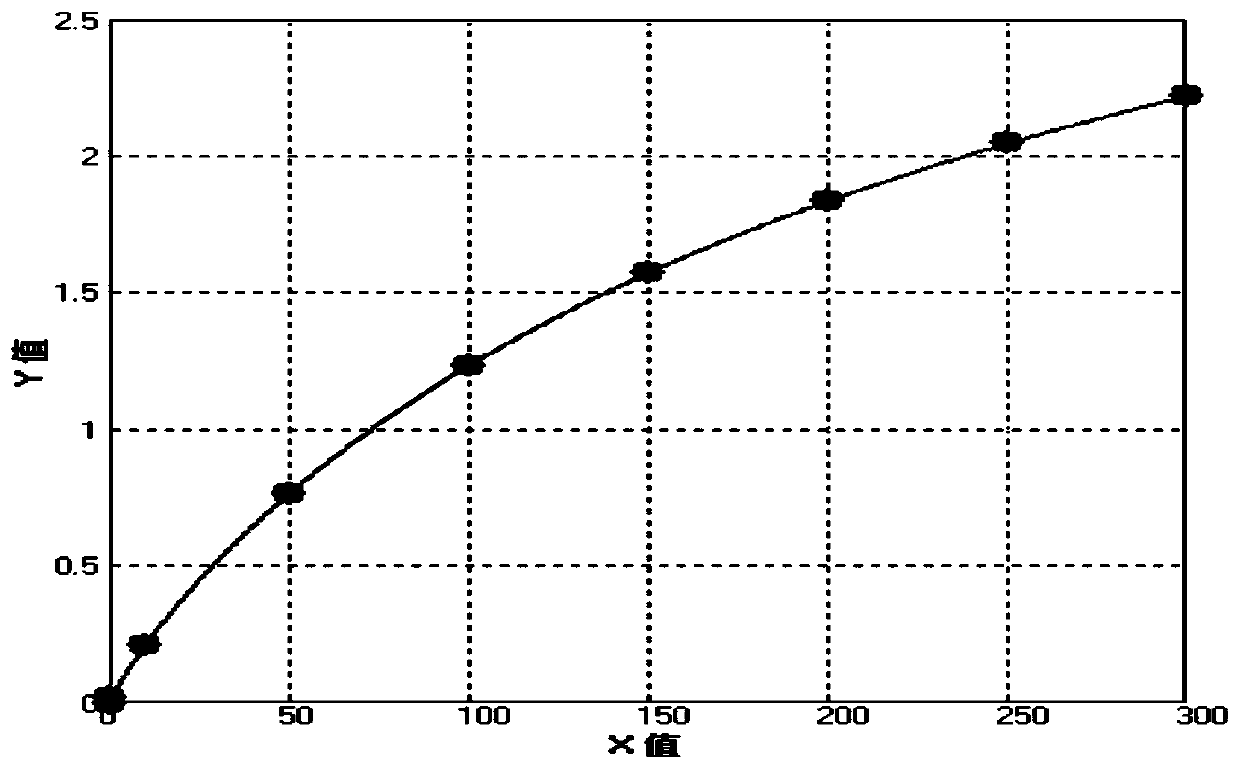

Image

Examples

Embodiment 1

[0102] 1) Preparation of latex precipitate:

[0103] The latex obtained by styrene-based polymerization is activated with NHS and EDC, and then chemically coupled with the corresponding antibody after the treatment. The latex conjugate with large particles was collected, and the latex solution was processed by centrifugation to obtain about 10 L of latex precipitate.

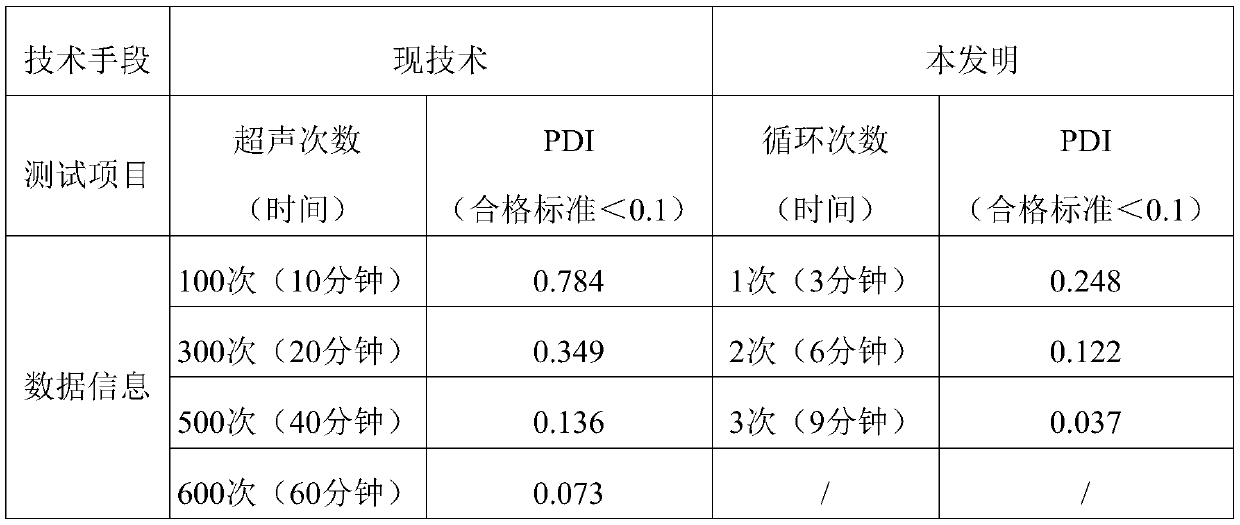

[0104] 2) The latex sediment is broken up:

[0105] The latex precipitate in 1) is equally divided into two parts (0.5 L per part), one part adopts the current technology (magnetic stirring or manual milling) to process, and the other part adopts the high-speed shearing machine of the present invention to carry out mechanical milling. With the same processing capacity, the present invention breaks up the processing time for about 5 to 6 minutes, while the prior art requires at least 2 hours for processing. After processing, it is large particle latex.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com