Self-healing hydrogel electrolyte film, and preparation method and application thereof

An electrolyte film and hydrogel technology, which is applied in the field of self-healing hydrogel electrolyte film and its preparation, can solve the problems of less cycles of fracture/repair, low mechanical properties of hydrogel electrolyte, and low energy, etc. Achieve good flexibility and repeatability, excellent self-healing properties, and high tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] To achieve the above purpose, the present invention provides a self-healing hydrogel electrolyte film and a preparation method thereof. The self-healing hydrogel electrolyte film of the present invention has broad application prospects in flexible electronic devices such as flexible stretchable supercapacitors.

[0029] The preparation method of the above-mentioned self-healing hydrogel electrolyte film comprises the following steps:

[0030] (1) Disperse [2-(methacryloyloxy)ethyl]dimethyl-(3-sulfonic acid propyl)ammonium hydroxide and methacrylic acid in deionized water, at 22~26°C at 200rpm Stir at a speed of / min~500rpm / min until a uniform and transparent solution A is obtained;

[0031] (2) Add a thermal initiator to solution A in step (1), and stir at a speed of 200 rpm / min to 500 rpm / min at 22 to 26 ° C until a uniform and transparent solution B is obtained;

[0032] (3) inject solution B in step (2) into glass molds with an interval of 500 μm to 1500 μm, and po...

Embodiment 1

[0035] Preparation of self-healing hydrogel electrolyte film

[0036] Step (1): Add 0.5g of [2-(methacryloyloxy)ethyl]dimethyl-(3-sulfonic acid propyl)ammonium hydroxide (DMAPS) monomer into 3ml of water;

[0037] Step (2): Add 2 g of methacrylic acid (AAc) into the solution in step 1, and stir at a speed of 200 rpm / min to 500 rpm / min for more than 10 min to obtain a uniform and transparent monomer aqueous solution.

[0038] Step (3): Add initiator 0.0126g ammonium persulfate to the mixed solution in step (2), and stir for 10 minutes.

[0039] Step (4): The mixed solution obtained in step (3) was injected into a glass mold with an interval of 1000 μm with a pipette gun, and polymerized at 60° C. for 6 hours to obtain a hydrogel.

[0040] Step (5): The hydrogel obtained in step (4) was swelled in 1M phosphoric acid aqueous solution for 24 hours until equilibrium, and a self-healing hydrogel electrolyte was obtained.

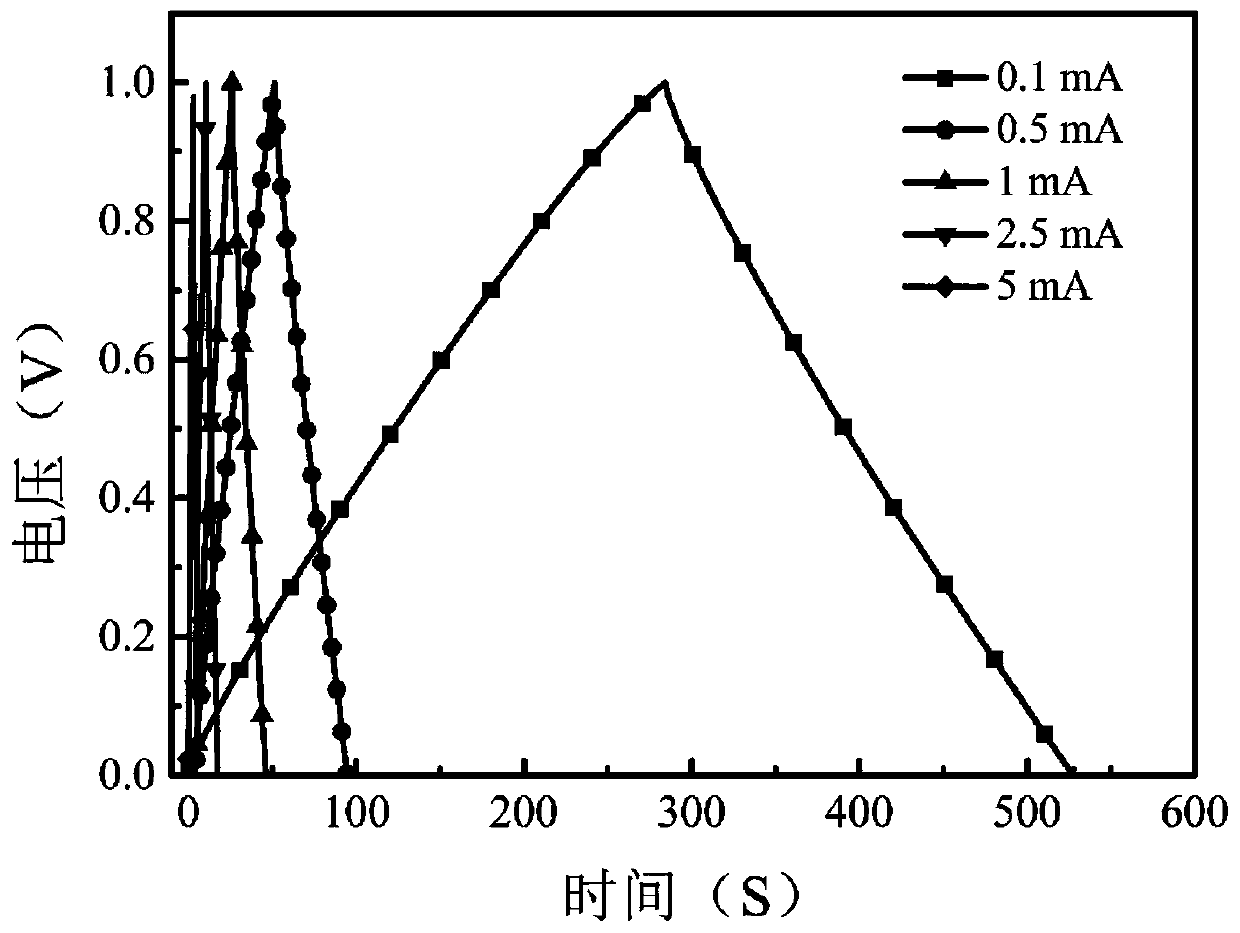

[0041] After the above steps, the self-healing polyelectro...

Embodiment 2

[0043] Preparation of self-healing hydrogel electrolyte film

[0044] Repeat Example 1 with the same steps, the difference is that in the step (5) by changing the phosphoric acid aqueous solution of different concentration to soak, obtain the hydrogel soaked with different concentration.

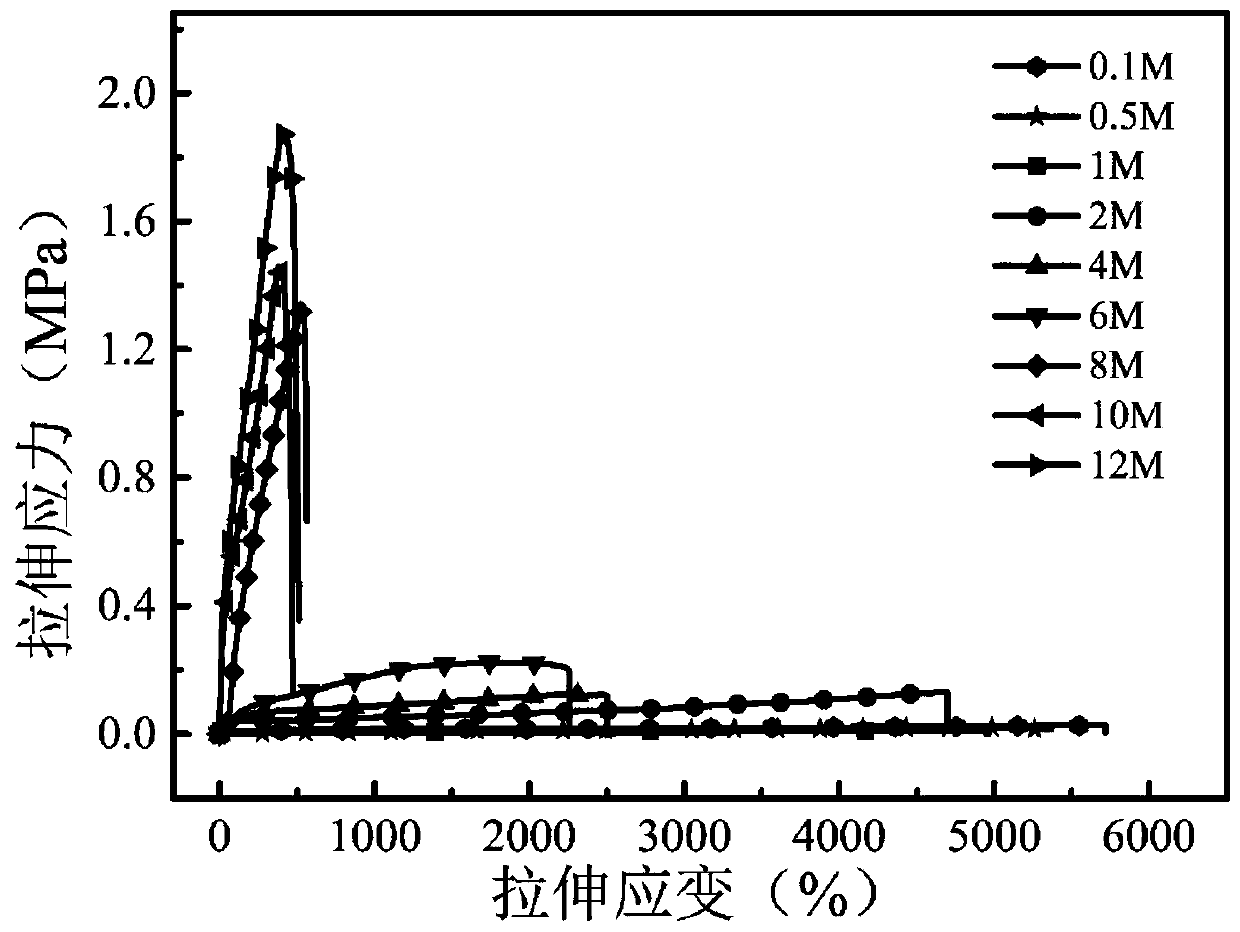

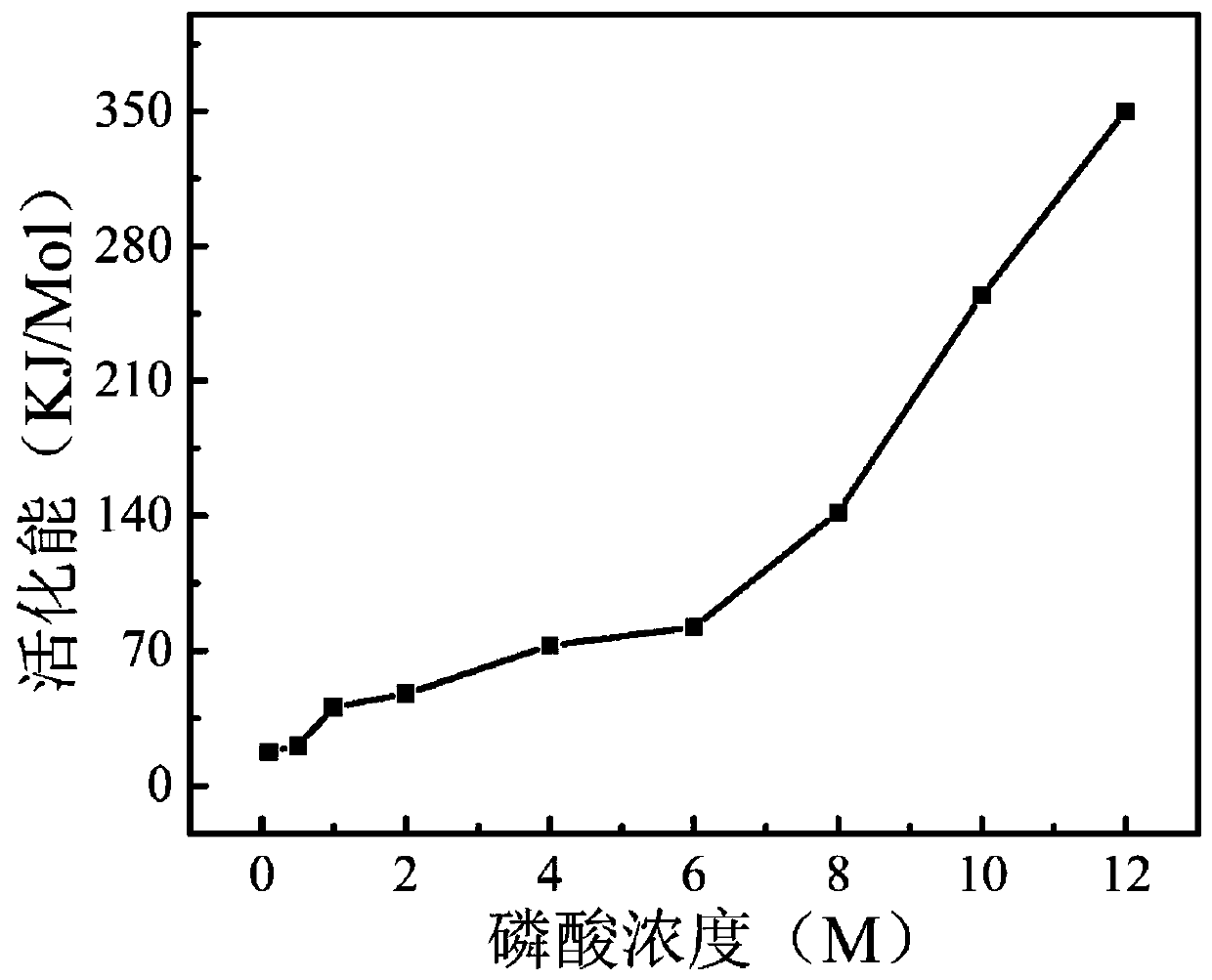

[0045] After the above steps, the modulus and volume of the hydrogel will change after soaking in different concentrations of phosphoric acid aqueous solution. As the concentration of phosphoric acid increases, the modulus of the hydrogel becomes larger and the stretchability becomes worse. ,like figure 1As shown, the stress-strain curves of the hydrogel soaked in different molar concentrations of phosphoric acid solutions, at 1M, the hydrogel can be stretched to 50 times the original, and the tensile modulus is 0.01MPa; when the concentration reaches 4M , the hydrogel can be stretched to 25 times the original, and the tensile modulus is 0.2MPa; when soaked in a low-concentration phosphoric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com