Processing method for improving tenderness of beef short ribs by using micro-organism fermentation

A technology of microbial fermentation and processing method, which is applied in the field of processing to improve the tenderness of cowboy bones, and can solve problems such as difficult chewing, heavy fishy smell, and hard meat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

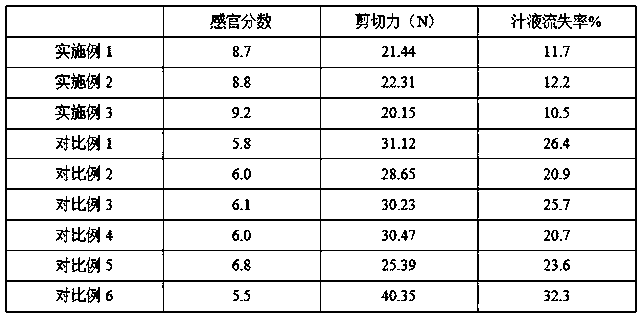

Examples

Embodiment 1

[0046] A processing method for improving the tenderness of cowboy bone by microbial fermentation, comprising the following steps:

[0047] Step 1: Cut the frozen cowboy bone (1kg) into small pieces of cowboy bone with a thickness of 1.0cm, a length of 8cm, and a width of 2cm with a bone saw machine (the blade of the bone saw machine is perpendicular to the muscle fiber of the cowboy bone), and then put it into Soak in an ultrasonic cleaner filled with alkaline electrolyzed water with a pH value of 8.0 (the mass ratio of small cowboy bones to alkaline electrolyzed water is 1:2, and the temperature of alkaline electrolyzed water is 10°C), supplemented by ultrasonic treatment (The power of ultrasonic treatment is 300W, and intermittent operation is adopted. The time of each ultrasonic treatment is 10min, and the time interval between two ultrasonic treatments is 5min). Concentration is 1g / L and the aseptic saline solution that contains edible salt mass concentration is 6g / L rinse...

Embodiment 2

[0053] A processing method for improving the tenderness of cowboy bone by microbial fermentation, comprising the following steps:

[0054] Step 1: Cut the frozen cowboy bone (1kg) into small pieces of cowboy bone with a thickness of 1.2cm, a length of 10cm, and a width of 4cm with a bone saw machine (the blade of the bone saw machine is perpendicular to the muscle fiber of the cowboy bone), and then put it into Soak in an ultrasonic cleaner filled with alkaline electrolyzed water with a pH value of 9.5 (the mass ratio of small cowboy bones to alkaline electrolyzed water is 1:3, and the temperature of alkaline electrolyzed water is 20°C), supplemented by ultrasonic treatment (The power of ultrasonic treatment is 400W, intermittent operation is adopted, the time of each ultrasonic treatment is 15min, and the time interval between two ultrasonic treatments is 5min), until the center temperature of the small cowboy bone is 1~5℃, and then use a mass of sodium bicarbonate Concentrat...

Embodiment 3

[0060] A processing method for improving the tenderness of cowboy bone by microbial fermentation, comprising the following steps:

[0061]Step 1: Cut the frozen cowboy bone (1kg) into small pieces of cowboy bone with a thickness of 1.1cm, a length of 9cm and a width of 3cm with a bone saw machine (the blade of the bone saw machine is perpendicular to the muscle fiber of the cowboy bone), and then put it into Soak in an ultrasonic cleaner filled with alkaline electrolyzed water with a pH value of 9.0 (the mass ratio of small cowboy bones to alkaline electrolyzed water is 1:2.5, and the temperature of alkaline electrolyzed water is 15°C), supplemented by ultrasonic treatment (The power of ultrasonic treatment is 350W, and intermittent operation is adopted. The time of each ultrasonic treatment is 12.5min, and the time interval between two ultrasonic treatments is 5min). Mass concentration is 1.5g / L and the aseptic saline solution that contains edible salt mass concentration is 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com