Preparation method of amic acid emulsion, and method for modifying surface of glass fiber with amic acid emulsion

A glass fiber and surface modification technology, which is applied in the preparation of amic acid emulsion and the surface modification of glass fiber, can solve the problems of poor interface temperature resistance and resin bonding effect, and achieve good heat resistance, less pollution, and good The effect of interface temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

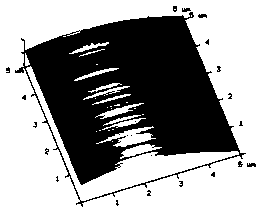

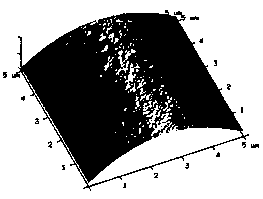

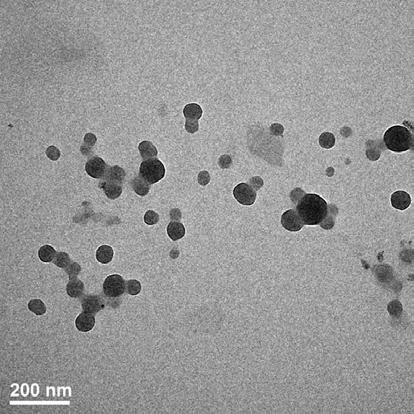

Image

Examples

Embodiment 1

[0032] This embodiment provides a preparation method of amic acid emulsion and its surface modification effect on glass fiber, including: 3,3',4,4'-benzophenonetetracarboxylic dianhydride, 4,4'-di Diphenyl ether, N,N'-dimethylformamide, polyvinylpyrrolidone and water. The mass percentage of each component in the total mass of the emulsion is expressed as follows:

[0033] (1) 3,3',4,4'-benzophenonetetracarboxylic dianhydride 0.2%

[0034] (2) 4,4'-Diaminodiphenyl ether 0.1%

[0035] (3) Polyvinylpyrrolidone 0.1%

[0036] (4) N,N'-dimethylformamide 25%

[0037] (5) The balance is deionized water.

[0038] The preparation method of the amic acid emulsion of this embodiment includes the following steps:

[0039] Step 1. Weigh each component raw material as required

[0040] Step 2: Dissolve 0.2g of 3,3',4,4'-benzophenonetetracarboxylic dianhydride in 25ml of N,N'-dimethylformamide at a temperature of 25℃, stir until the solid is fully dissolved, and then add 0.1g 4,4'-diaminodiphenyl ether...

Embodiment 2

[0050] This embodiment provides a preparation method of amic acid emulsion and its surface modification effect on glass fiber, including: pyromellitic anhydride, 4,4'-diaminodiphenyl ether, N,N'-dimethyl Formamide, polyethylene glycol and water. The mass percentage of each component in the total mass of the emulsion is expressed as follows:

[0051] (1) Pyromellitic anhydride 0.227%

[0052] (2) 4,4'-Diaminodiphenyl ether 0.173%

[0053] (3) Polyethylene glycol 0.05%

[0054] (4) N,N-Dimethylformamide 20%

[0055] (5) The balance is deionized water.

[0056] The preparation method of the amic acid emulsion of this embodiment includes the following steps:

[0057] Step 1. Weigh each component raw material as required

[0058] Step 2: Dissolve 0.227g of pyromellitic anhydride in 20ml of N,N'-dimethylformamide at a temperature of 20℃, stir until the solid is fully dissolved, then add 0.173g of 4,4'-diaminodiphenyl Ether, stir until the solid is fully dissolved and then stand for 5 min to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com