Calcium acetate pharmaceutical composition and preparation method and application thereof

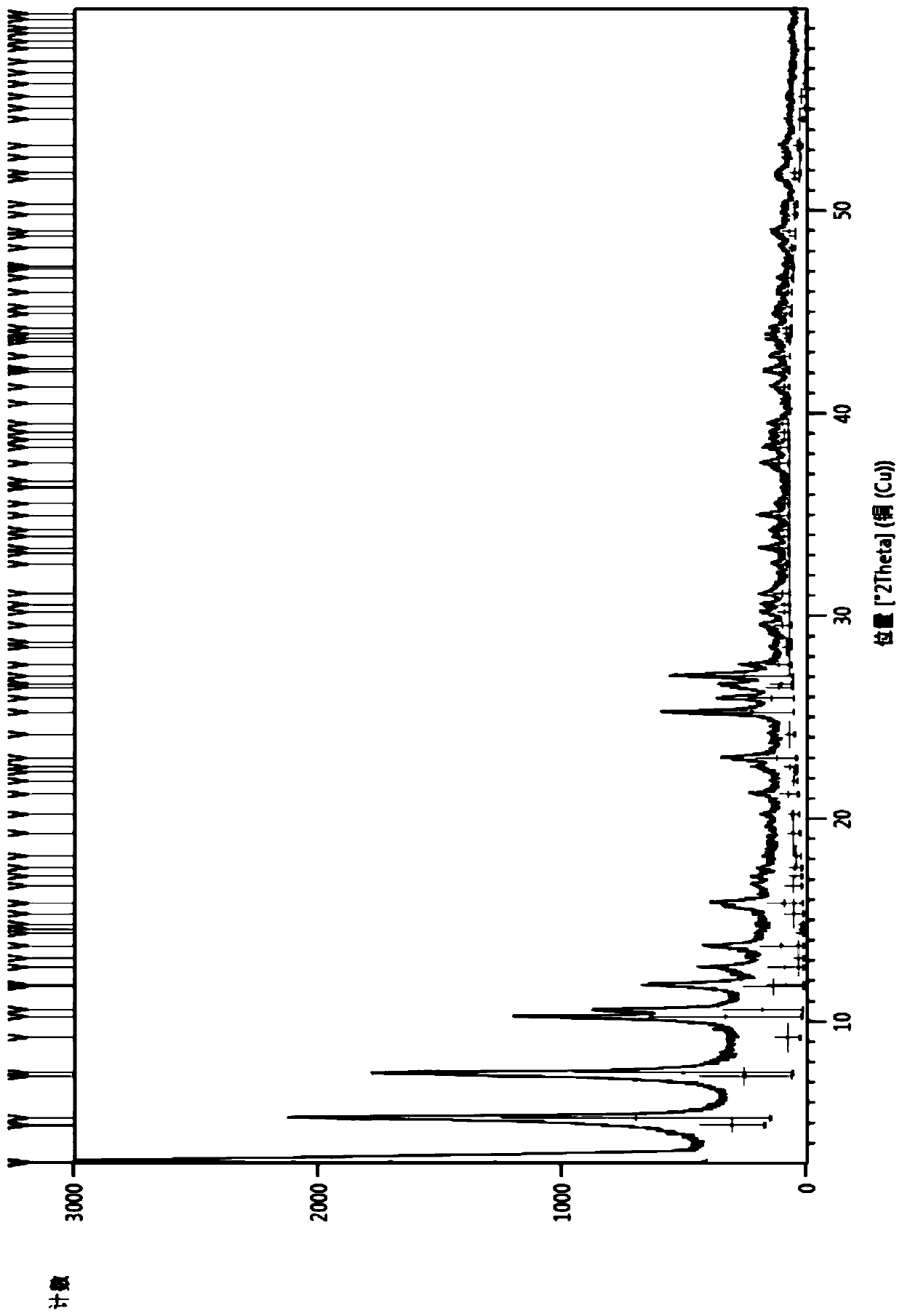

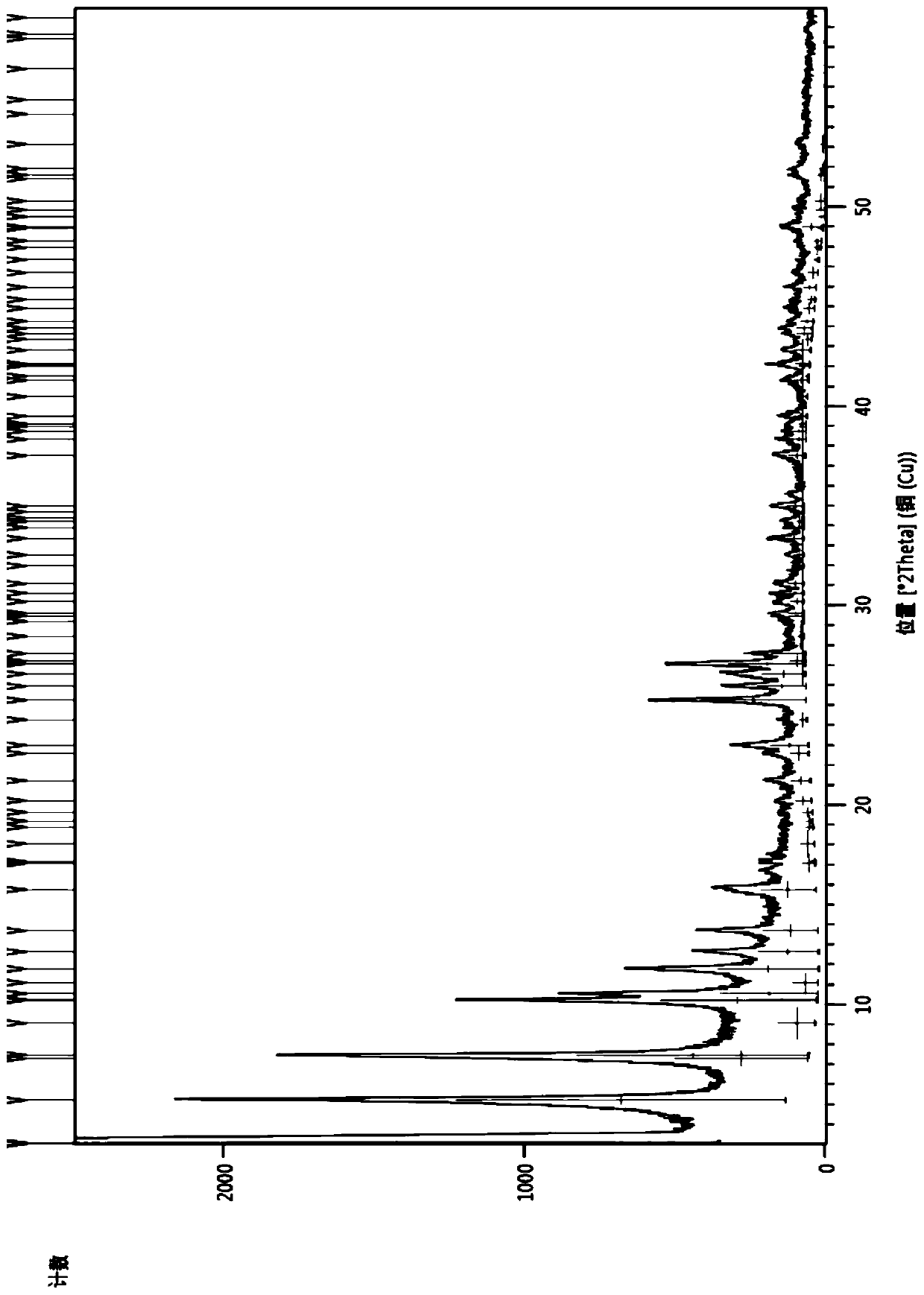

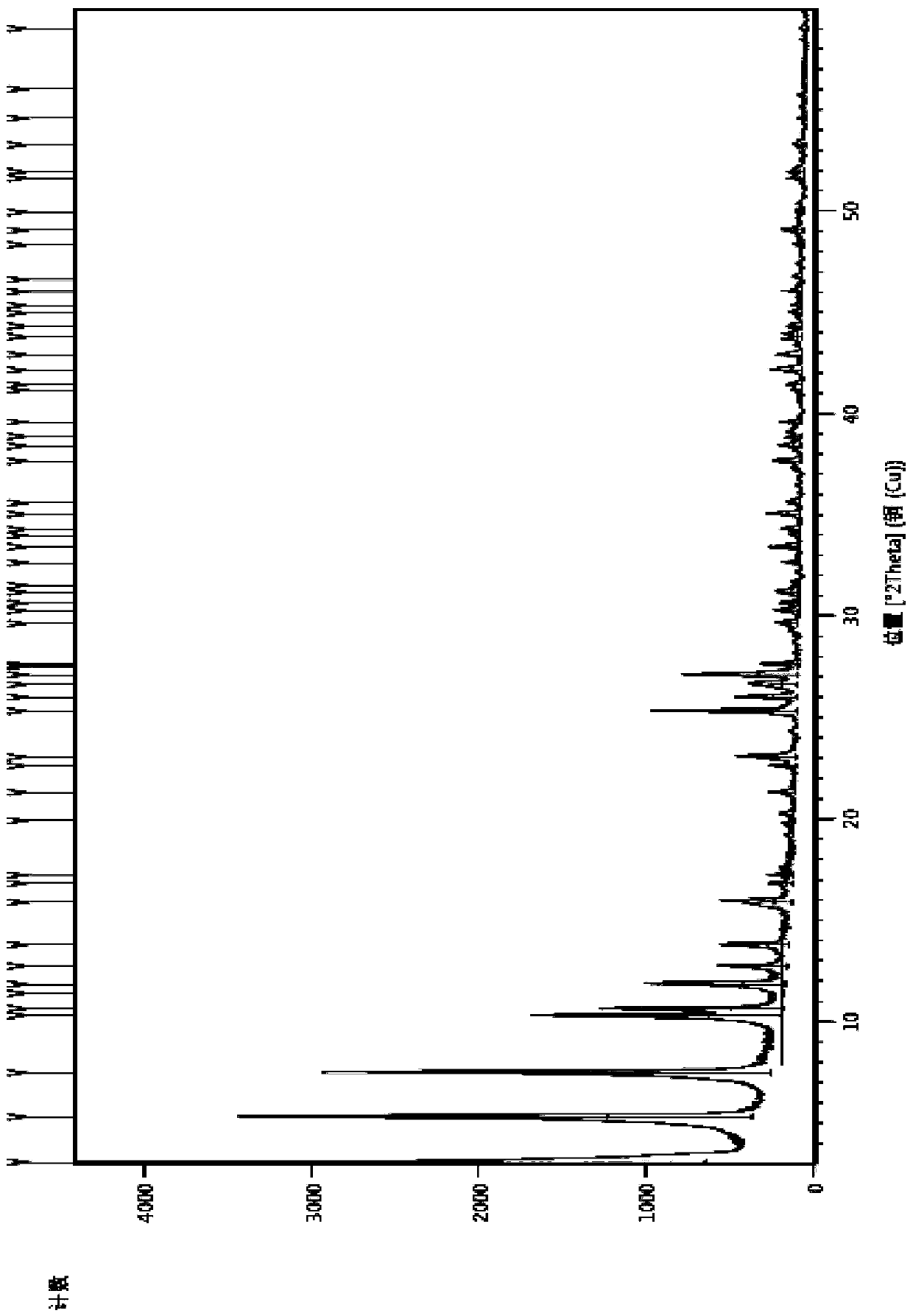

A technology of calcium acetate and composition, applied in the field of calcium acetate pharmaceutical composition and preparation thereof, can solve problems such as inconsistent crystal forms, and achieve the effects of ensuring stability and avoiding dissolution behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] In yet another specific embodiment of the present invention, a method for preparing a calcium acetate pharmaceutical composition through crystal transformation is provided, and the operation steps are as follows:

[0042] (1) Take calcium acetate raw material according to the prescription, place it in a wet granulator, add 30%-95% ethanol to granulate, and the granulation state is that the granules are wet and bonded into agglomerates;

[0043] (2) Seal the wet granules, place them at room temperature for 0.5h-24h, and then wet the granules;

[0044] (3) The sized granules are dried at 60° C. to 150° C., and the moisture content is controlled to be 5% to 6.5%, and the granules are sized.

[0045] (4) Mix the obtained dry granules with the added excipients and lubricant in the prescription ratio evenly, and press into tablets to obtain calcium acetate tablets.

[0046] In yet another specific embodiment of the present invention, a method for preparing a calcium acetate ...

Embodiment 1

[0054] Calcium acetate tablet prescription: specification 667mg (in C 4 h 6 CaO 4 meter), the prescription quantity is 1000 tablets.

[0055] name Single dose mg / tablet g / 1000 tablets calcium acetate 667 700.321 polyethylene glycol 8000 10 10.003 Magnesium stearate 3.5 3.505

[0056] Preparation:

[0057] (1) Take calcium acetate raw material according to prescription, place in wet granulator, add 50% ethanol 320ml and carry out granulation, the state of granulation is that granule is wet, bonded into agglomerate;

[0058] (2) Seal the wet granules, place them at room temperature for 6 hours, and then wet the granules;

[0059] (3) Dry the sized granules at 130° C. for 2 hours, control the moisture range to 5%-6.5%, and granulate.

[0060] (4) Mix the obtained dry granules with polyethylene glycol 8000 and magnesium stearate according to the prescription ratio, and press into tablets to obtain calcium acetate tablets.

Embodiment 2

[0062] Calcium acetate tablet prescription: specification 667mg (in C 4 h 6 CaO 4 meter), the prescription quantity is 1000 tablets.

[0063]

[0064]

[0065] Preparation:

[0066] (1) Take calcium acetate raw material according to prescription, place in wet granulator, add 50% ethanol 300ml and carry out granulation, granulation state is that granule is wet, sticks into agglomerate;

[0067] (2) Seal the wet granules, place them at room temperature for 12 hours, and then wet the granules;

[0068] (3) Dry the sized granules at 120° C. for 6 hours, control the moisture range to 5%-6.5%, and granulate.

[0069] (4) Mix the obtained dry granules with polyethylene glycol 8000 and magnesium stearate according to the prescription ratio, and press into tablets to obtain calcium acetate tablets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com