Preparation method and application of functionalized graphene-based aerogel

A technology of airgel and graphene, which is applied in the field of preparation of functionalized graphene-based airgel, can solve problems such as unsatisfactory adsorption performance, and achieve the effects of high specific surface area, increased adsorption capacity, and high adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

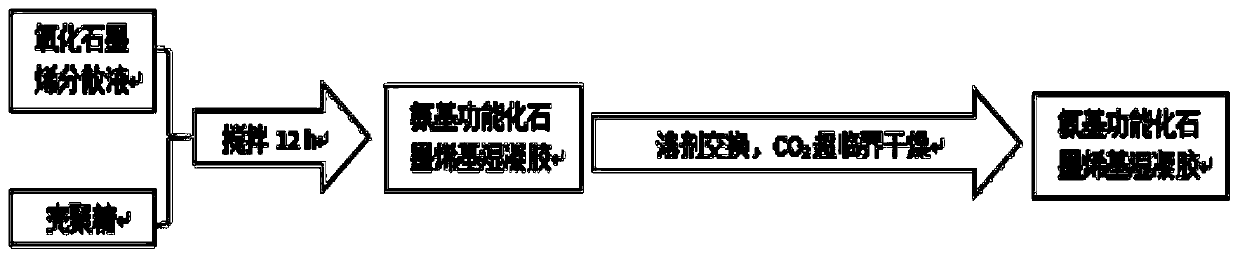

[0029] A preparation method of functionalized graphene-based airgel, comprising the following steps:

[0030] Step 1. Add 60 mg of chitosan to 30 mL of graphene oxide dispersion, then adjust the pH to 6-7 with 1 mol / L hydrochloric acid, and stir to obtain a mixed solution; the concentration of the graphene oxide dispersion is 2 mg / mL ;

[0031] Step 2, adding the mixed solution into a high-pressure reactor for hydrothermal reaction to obtain a wet gel; the temperature of the hydrothermal reaction is 180° C., and the reaction time is 12 hours;

[0032] Step 3: Soak the wet gel in alcohol and acetone for 3 times in sequence, 24 hours each time, and finally use CO 2 Functionalized graphene-based aerogels were obtained by supercritical drying.

Embodiment 2

[0034] A preparation method of functionalized graphene-based airgel, comprising the following steps:

[0035] Step 1, add 120mg chitosan in 30mL graphene oxide dispersion liquid, then adopt 1mol / L hydrochloric acid to adjust pH to 6~7, stir, obtain mixed liquid; The concentration of described graphene oxide dispersion liquid is 2mg / mL ;

[0036] Step 2, adding the mixed solution into a high-pressure reactor for hydrothermal reaction to obtain a wet gel; the temperature of the hydrothermal reaction is 180° C., and the reaction time is 12 hours;

[0037]Step 3: Soak the wet gel in alcohol and acetone for 3 times in sequence, 24 hours each time, and finally use CO 2 Functionalized graphene-based aerogels were obtained by supercritical drying.

Embodiment 3

[0039] A preparation method of functionalized graphene-based airgel, comprising the following steps:

[0040] Step 1, add 240mg chitosan in 30mL graphene oxide dispersion liquid, then adopt 1mol / L hydrochloric acid to adjust pH to 6~7, stir, obtain mixed liquid; The concentration of described graphene oxide dispersion liquid is 2mg / mL ;

[0041] Step 2, adding the mixed solution into a high-pressure reactor for hydrothermal reaction to obtain a wet gel; the temperature of the hydrothermal reaction is 180° C., and the reaction time is 12 hours;

[0042] Step 3: Soak the wet gel in alcohol and acetone for 3 times in sequence, 24 hours each time, and finally use CO 2 Functionalized graphene-based aerogels were obtained by supercritical drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com