Method of efficiently degrading water-produced hydrogen based on conjugated porous organic photocatalyst

A photocatalyst and water splitting technology, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of low hydrogen production performance and uncertain hydrogen source. Methanol, unable to promote the separation of photogenerated electrons and holes, etc., to achieve the effect of promoting separation, improving hydrogen production performance, and promoting effective dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

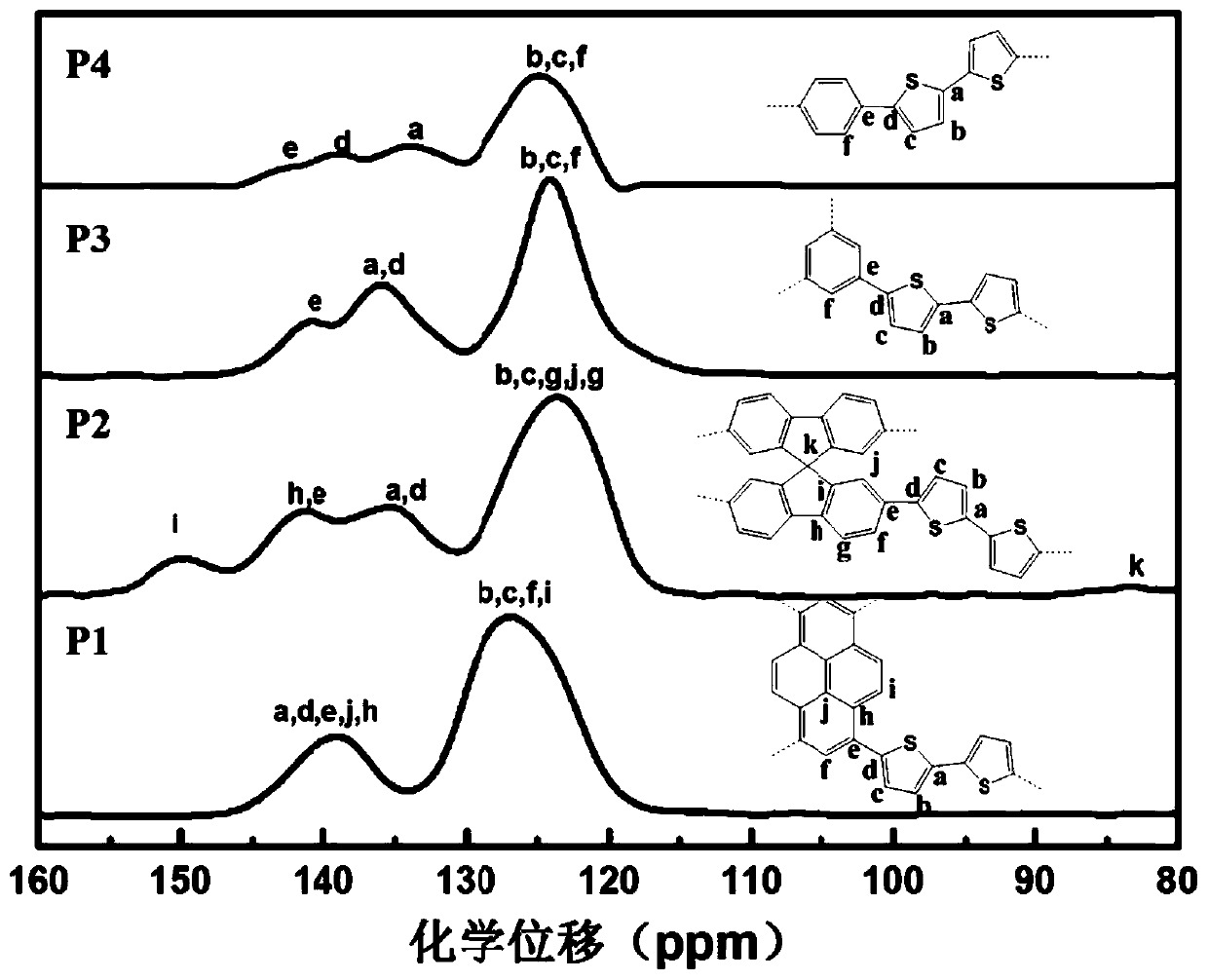

[0037] Preparation Example 1 Preparation of Conjugated Porous Organic Photocatalyst P1

[0038] In a 25mL Schlenk tube, add 1,3,6,8-tetrabromopyrene (0.386mmol, 200.0mg), 5,5′-bis(trimethyltinyl)-2,2′-bithiophene (0.772mmol , 379.9mg), P(o-MeOPh) 3 (0.039mmol, 10.9mg), Pd 2 dba 3 (0.015mmol, 14.1mg) and 10ml of a mixture of toluene / DMF (19:1, v / v). The mixture was degassed under the thawing of the refrigeration pump, purged with argon, stirred at 110°C for 48h, cooled to room temperature and poured into CH 2 Cl 2 , and filtered to obtain the crude product. The resulting crude product was extracted and separated, and CH was added successively. 2 Cl 2 , methanol, NaF solution, water and methanol to purify, remove inorganic salts, unreacted raw materials and other impurities in the reactant, and vacuum-dry the resulting solid product to obtain a conjugated porous organic semiconductor material, denoted as P1.

preparation example 2

[0039] Preparation Example 2 Preparation of Conjugated Porous Organic Photocatalyst P2

[0040] In a 25 mL Schlenk tube, add 2,2′,7,7′-tetrabromospirofluorene (0.386 mmol, 243.9 mg), 5,5′-bis(trimethyltinyl)-2,2′-bithiophene (0.772 mmol, 379.9 mg), P(o-MeOPh)3 (0.039 mmol, 10.9 mg), Pd2dba3 (0.015 mmol, 14.1 mg) and 10 ml of a mixture of toluene / DMF (19:1, v / v). The mixture was degassed under the thawing of the refrigeration pump, purged with argon, stirred at 110°C for 48h, cooled to room temperature and poured into CH 2 Cl 2 , and filtered to obtain the crude product. The resulting crude product was extracted and separated, and CH was added successively. 2 Cl 2 , methanol, NaF solution, water and methanol to purify, remove inorganic salts, unreacted raw materials and other impurities in the reactant, and vacuum-dry the resulting solid product to obtain a conjugated porous organic semiconductor material, denoted as P2.

preparation example 3

[0041] Preparation Example 3 Preparation of Conjugated Porous Organic Photocatalyst P3

[0042] In a 25mL Schlenk tube, add 1,3,5-tribromobenzene (0.515mmol, 162.0mg), 5,5′-bis(trimethyltinyl)-2,2′-bithiophene (0.772mmol, 379.9 mg), a mixture of P(o-MeOPh)3 (0.039mmol, 10.9mg), Pd2dba3 (0.015mmol, 14.1mg) and 10ml of toluene / DMF (19:1, v / v). The mixture was degassed under the thawing of the refrigeration pump, purged with argon, stirred at 110°C for 48h, cooled to room temperature and poured into CH 2 Cl 2 , and filtered to obtain the crude product. The resulting crude product was extracted and separated, and CH was added successively. 2 Cl 2 , methanol, NaF solution, water and methanol purification to remove inorganic salts, unreacted raw materials and other impurities in the reactant, vacuum-dry the resulting solid product to obtain a conjugated porous organic semiconductor material, denoted as P3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com