Method and device for treating rosin modified phenolic resin industrial wastewater

A technology of phenolic resin and industrial wastewater, applied in multi-stage water treatment, water/sewage treatment, natural water treatment, etc., can solve the self-built biochemical method site, capital, technical difficulty, one-time investment and land occupation of biochemical method Large size, odor and other problems, to achieve the effect of small footprint of the implementation equipment, easy operation, and reduced consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

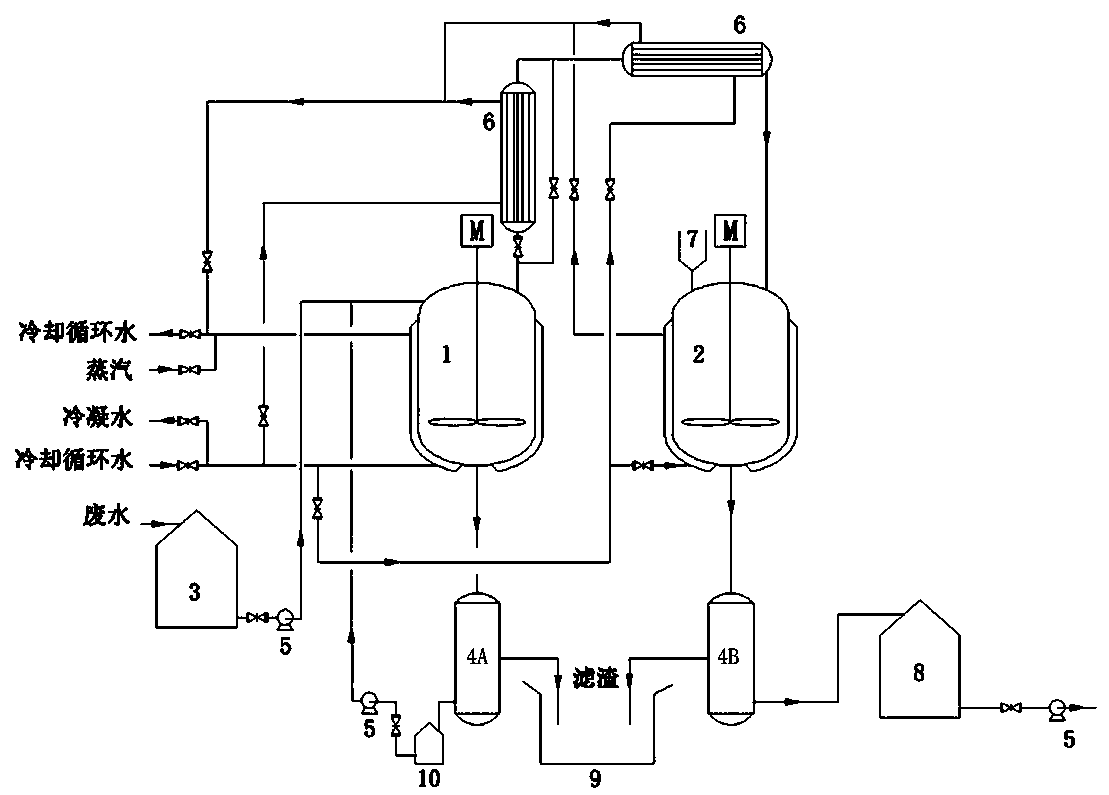

Method used

Image

Examples

Embodiment 1

[0042] Rosin modified phenolic resin wastewater, COD Cr The content of formaldehyde is 50000 mg / L, the content of formaldehyde is 80 g / L, the content of volatile phenol is 2 g / L, and the content of NaCl is 70 g / L. Pump the waste water into the pre-reactor, put in 5% CaO of the waste water, start stirring, and pass superheated steam into the jacket of the pre-reactor to keep the temperature of the waste water at 89°C and reflux for 4 hours. Open the bypass valve, evaporate the waste water at 97°C, and condense the waste water into the reactor. When the total amount of condensed waste water evaporated reaches 70% of the waste water, the jacket of the pre-reaction kettle is replaced with circulating cooling water. When the temperature of the waste water in the kettle drops to 40°C, the bottom valve is opened, filtered, and the filtrate is drained. into the pre-reaction kettle, and the filter residue is placed in the filter residue temporary storage tank. Condensed waste water C...

Embodiment 2

[0044] Rosin modified phenolic resin wastewater, COD Cr The content of formaldehyde is 34000 mg / L, the content of formaldehyde is 70 g / L, the content of volatile phenol is 1.5 g / L, and the content of KCl is 60 g / L. The waste water was pumped into the pre-reactor, and after inputting 4% KOH of the waste water quality, stirring was started, and superheated steam was introduced into the jacket of the pre-reactor to keep the temperature of the waste water at 87°C and reflux for 4 hours. Open the bypass valve, evaporate the waste water at 96 °C, and condense the waste water into the reactor. When the total amount of condensed waste water evaporated reaches 70% of the waste water, the jacket of the pre-reaction kettle is replaced with circulating cooling water. When the temperature of the waste water in the kettle drops to 40°C, the bottom valve is opened, filtered, and the filtrate is drained. into the pre-reaction kettle, and the filter residue is placed in the filter residue tem...

Embodiment 3

[0046] Rosin modified phenolic resin wastewater, COD Cr 25000 mg / L, formaldehyde content 60 g / L, volatile phenol content 1.2 g / L, MgCl 2 Content 60 g / L. Pump the waste water into the pre-reactor, put in 2% NaOH of the waste water, start stirring, and pass superheated steam into the jacket of the pre-reactor to keep the temperature of the waste water at 85°C and reflux for 4 hours. Open the bypass valve, evaporate the waste water at 98 °C, and condense the waste water into the reactor. When the total amount of evaporated condensate reaches 70% of the waste water, the jacket of the pre-reaction kettle is replaced with circulating cooling water. When the temperature of the waste water in the kettle drops to 40°C, the bottom valve is opened, filtered, and the filtrate is drained. into the pre-reaction kettle, and the filter residue is placed in the filter residue temporary storage tank. In the condensed wastewater in the reactor, adjust the pH value to 4 with sulfuric acid, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com