Vanadium dioxide composite thin film with adjustable transmissivity, and preparation method thereof

A technology of vanadium dioxide and composite thin film, which is applied in liquid chemical plating, metal material coating technology, coating, etc., can solve the problems of complex thin film system, cumbersome regulation and preparation process, etc., achieve a wide range of applications, and avoid easy oxidation , Improve the effect of phase transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

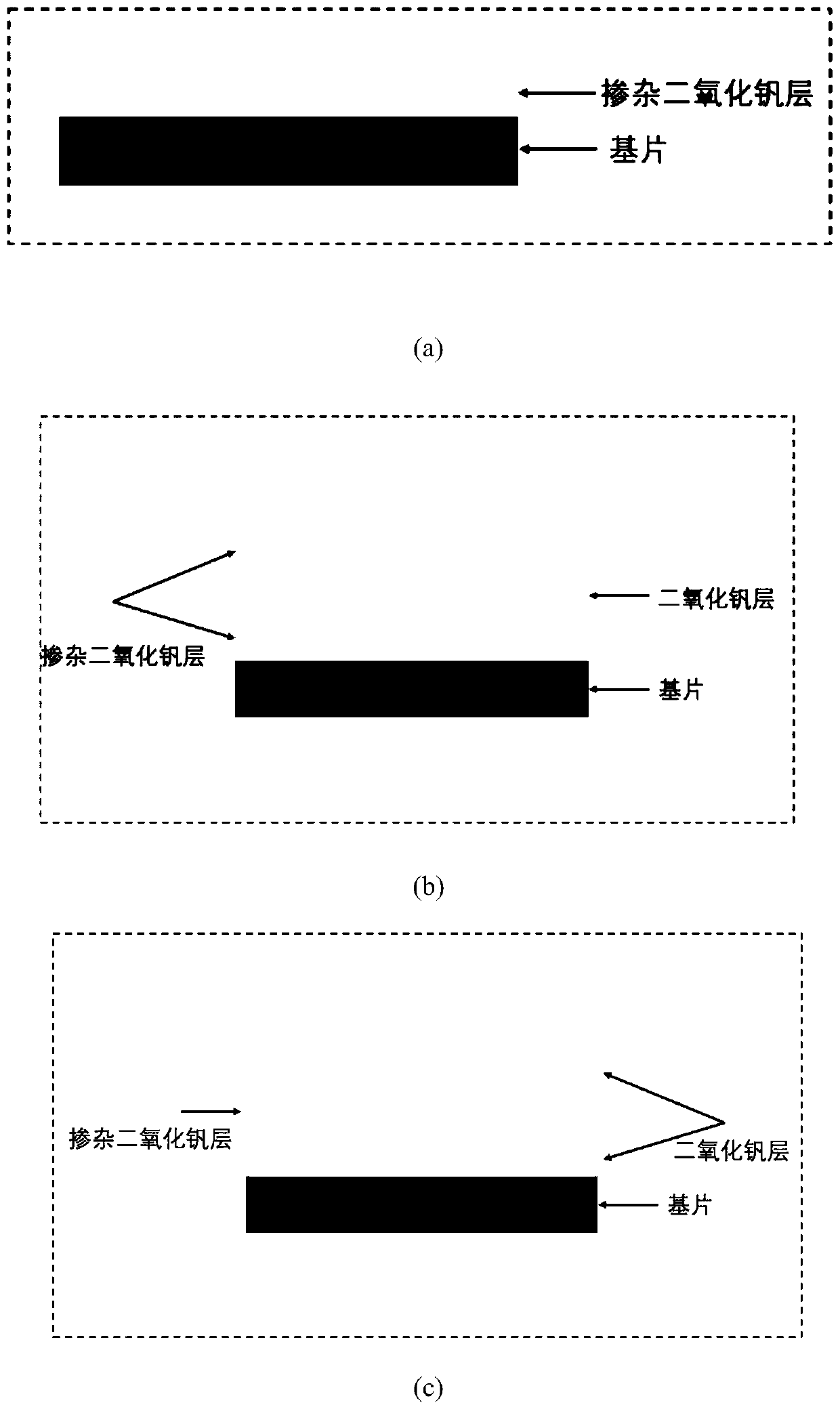

[0037] A method for preparing a vanadium dioxide composite film with adjustable transmittance, specifically comprising the following steps:

[0038] Step 1: Configure vanadium ion precursor solution and tungsten ion precursor solution by PAD (Polymer assisted deposition) method;

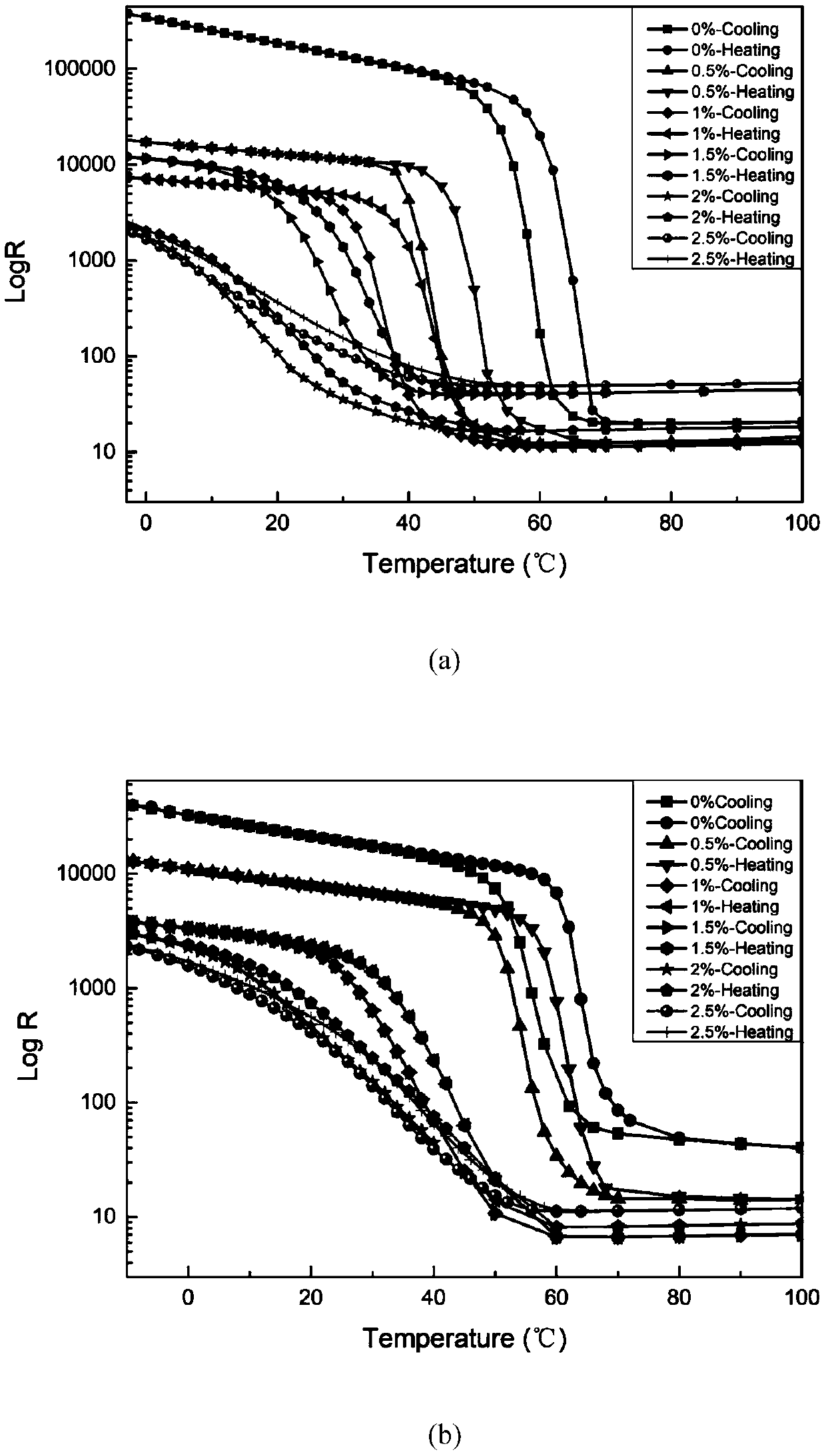

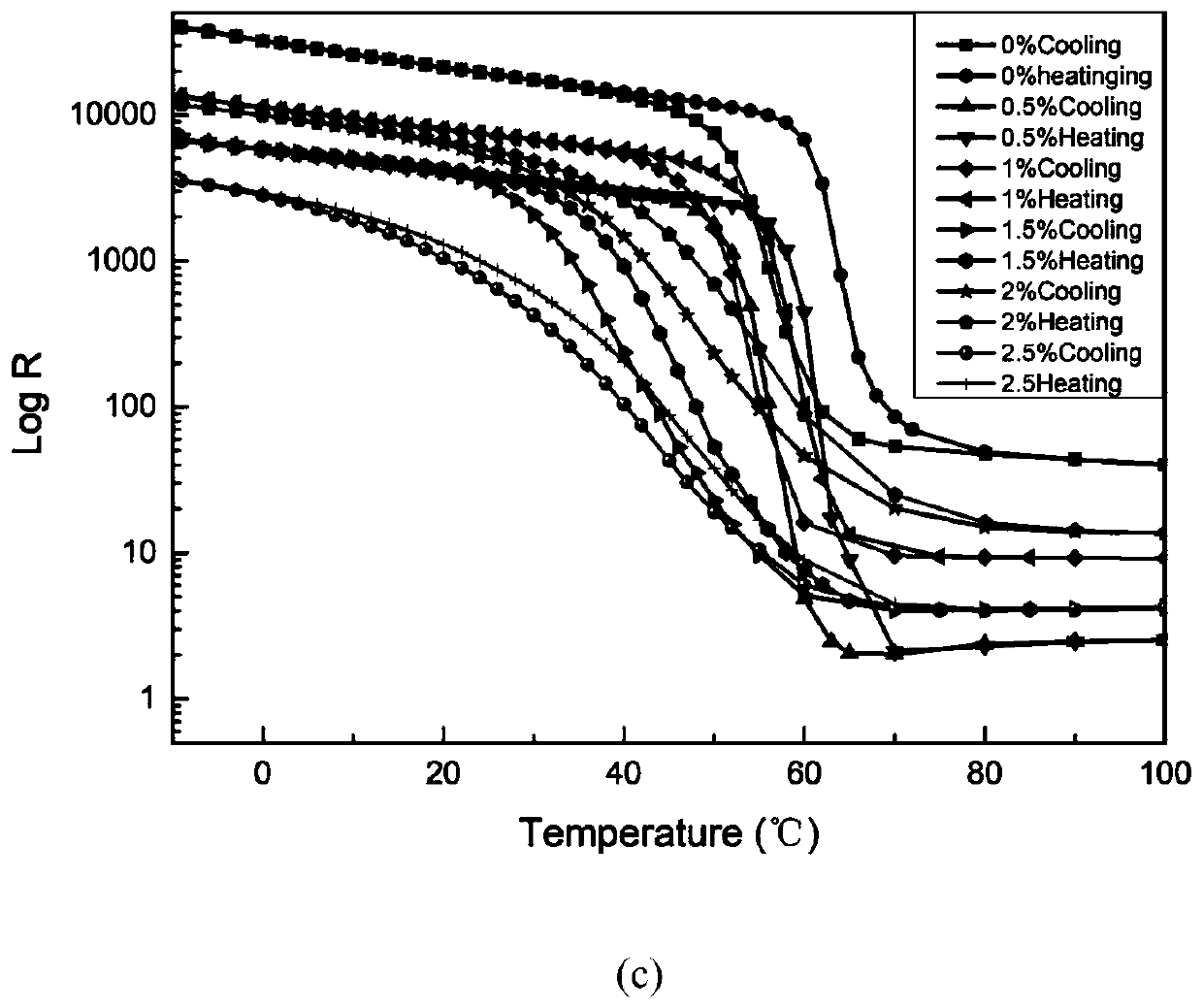

[0039] Step 2: Mix the vanadium ion precursor solution and the tungsten ion precursor solution in proportion to obtain a mixed solution, wherein the mass percentage of the tungsten ion precursor solution in the mixed solution is 0.5%, 1%, 1.5%, 2% and 2.5% ;

[0040] Step 3: Ultrasonic clean the substrate with acetone, absolute ethanol and deionized water for 10 minutes, and then dry it with nitrogen for later use;

[0041]Step 4: Spin-coat the mixed solution prepared in step 2 on the cleaned sapphire substrate by spin coating, keep it at a speed of 650r / min for 12s at a low speed, and keep it at a speed of 7000r / min for 40s at a high speed;

[0042] Step 5: Put the substrate spin-coated in step 4 ...

Embodiment 2

[0048] A method for preparing a vanadium dioxide composite film with adjustable transmittance, specifically comprising the following steps:

[0049] Step 1: Configure vanadium ion precursor solution and tungsten ion precursor solution by PAD (Polymer assisted deposition) method;

[0050] Step 2: Mix the vanadium ion precursor solution and the tungsten ion precursor solution in proportion to obtain a mixed solution, wherein the mass percentage of the tungsten ion precursor solution in the mixed solution is 0.5%, 1%, 1.5%, 2% and 2.5% ;

[0051] Step 3: Ultrasonic clean the substrate with acetone, absolute ethanol and deionized water for 10 minutes, and then dry it with nitrogen for later use;

[0052] Step 4: Spin-coat the vanadium ion precursor solution prepared in step 1 on the cleaned sapphire substrate, keep it at a low speed of 650r / min for 12s, and high speed at a speed of 7000r / min for 40s;

[0053] Step 5: Put the substrate spin-coated in step 4 into a tube furnace, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com