A method of using solid waste to melt glass at high temperature to make building materials

A high-temperature melting and solid waste technology, which is applied to the removal of solid waste, chemical instruments and methods, transportation and packaging, etc., can solve problems such as poor volume stability, and achieve the effect of increasing added value and utilization channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

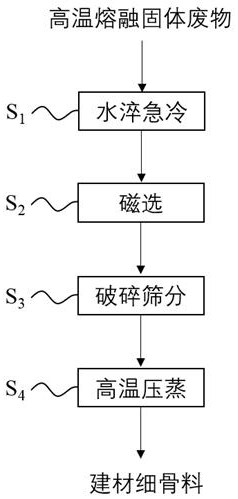

[0019] A method of using solid waste to melt glass at high temperature to make building materials of the present invention comprises the following steps:

[0020] S 1 :Water quenching: domestic waste incineration fly ash is melted and liquefied at high temperature in the plasma melting furnace, and the molten liquid continuously overflows to the outside of the furnace, and is rapidly cooled in mid-air by 0.3Mpa slag quenching water and falls into the slag pool. The clear water in the slag pool further cools the water-quenched slag and reacts with free calcium oxide and free magnesium oxide in the water-quenched slag. The water-quenched slag stays in the slag pool for half an hour and is discharged from the discharge device. The particle size distribution is between 1 and 10 mm.

[0021] S 2 : Magnetic separation: use magnetic separation device to separate the magnetic metal substances in the water-quenched slag.

[0022] S 3 : Crushing and screening: The water-quenched sla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com