A closed treatment process and equipment for organic sludge

A closed treatment, organic matter technology, used in dewatering/drying/concentrating sludge treatment, grain treatment, lighting and heating equipment, etc., can solve the problems of large heat loss, non-circulating operation, high energy consumption, and achieve production area occupation. Small area, energy saving, compact and reasonable process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

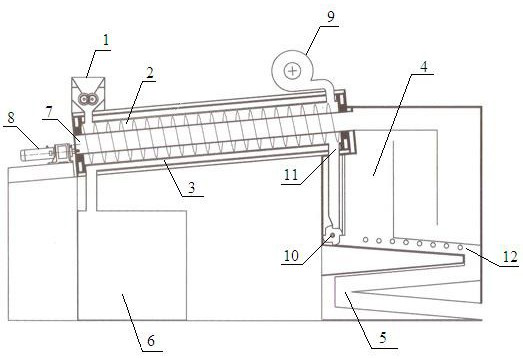

Image

Examples

Embodiment 1

[0039] The closed treatment process of organic sludge of the present invention comprises the following steps:

[0040] (1) Crush the sludge to a particle size below 5mm, and enter the drying pipe from the feeder;

[0041] (2) The sludge is subjected to the direct heat transfer of 600~800°C high-temperature combustion gas in the drying pipe and the indirect heat transfer of the inner and outer pipe walls. At the same time, the negative pressure of -30~-5kpa in the drying pipe is controlled to make the moisture in the sludge Evaporate at about 75~95℃, and after 20~30 minutes, the water in the sludge is completely dry;

[0042] (3) The dried sludge enters the combustion chamber. The combustion chamber is a negative pressure vertical furnace with electric and gas heating as the auxiliary heat source. The combustion chamber maintains a temperature of 850~880°C. The sludge enters the combustion section from the outlet end of the inner tube of the drying tube. Fully contact with the...

Embodiment 2

[0048] The closed treatment process of organic sludge of the present invention comprises the following steps:

[0049] (1) Crush the sludge to a particle size below 5mm, and enter the drying pipe from the feeder;

[0050] (2) The sludge is subjected to the direct heat transfer of 650~750°C high-temperature combustion gas in the drying pipe and the indirect heat transfer of the inner and outer pipe walls. Evaporate at about 90~95℃, and after 20~30 minutes, the water in the sludge is completely dry;

[0051] (3) The dried sludge enters the combustion chamber. The combustion chamber is a negative pressure vertical furnace, with electric and gas heating as the auxiliary heat source. The combustion chamber maintains a temperature of 860~870°C. The sludge enters the combustion section from the outlet end of the inner tube of the drying tube. Fully contact with the air and burn, the residence time is not less than 20 seconds, and completely burn the organic matter in the sludge. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com